Jalil Shaik is COO of UniPixel of the US and used to be with Atmel before that company’s touch business was acquired by UniPixel. He talked about UniPixel’s metal mesh technology which is used for touch sensors

Jalil Shaik is COO of UniPixel of the US and used to be with Atmel before that company’s touch business was acquired by UniPixel. He talked about UniPixel’s metal mesh technology which is used for touch sensors

The touch sensor market has a $7 billion total available market (TAM) and the market segments that UniPixel operates in have a TAM of $5 billion, Shaik said. The firm believes it is the market leader in tablets, laptops and “2 in 1″s. The firm’s metal mesh is based on copper, which helps with resistivity.

The smartphone touch sensor market is worth $3.6 billion, tablets $1.1 billion and notebooks at $136 million (based on 20% penetration) and Shaik said that Unipixel’s technology could really help the 20% penetration in notebooks get much closer to 100%.

The firm had 26 design wins in 2016 and a big factor in that success is the support of stylus operation (used in Microsoft Surface and becoming more important to system suppliers).

The automotive market was 29 million units in 2013, but is expected to grow to 60 million markets in 2018, Shaik said, based on forecasts from IHS

Unipixel’s Touch Solution

UniPixel makes the touch sensor component and these are supplied to module makers who laminate them onto the final display and fit the cover glass.

The company’s technology has 90% transmission and the borders can be very thin because of the low resistivity, so tracking can be done from one side, rather than two in the case of ITO-based sensors. The low resistivity helps to get very low sheet resistance which improves sensitivity and noise resistance. The single sided tracking allows single routing of the signals around the edge of the display.

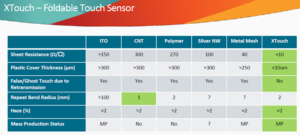

Unipixel presented this table of benefits that highlights why Unipixel has been getting design wins.

There were twenty or thirty suppliers who were looking to develop metal mesh solutions, but that number is now down to three – two of whom are shipping “everything they can make” – the others gave up because of the difficulties of entering the market. With low resistivity materials such as copper (<10Ω/sq), just 4% of the display area is covered by the conductors, so good optical efficacy can be achieved. The metal mesh material is bendable and it has good moisture resistance.

UniPixel thinks that every flexible display will have to have touch. If the display bends, the touch sensor will bend. Shaik believes that every touch display will, one day, also need stylus support – it has been very important on the Microsoft Surface.

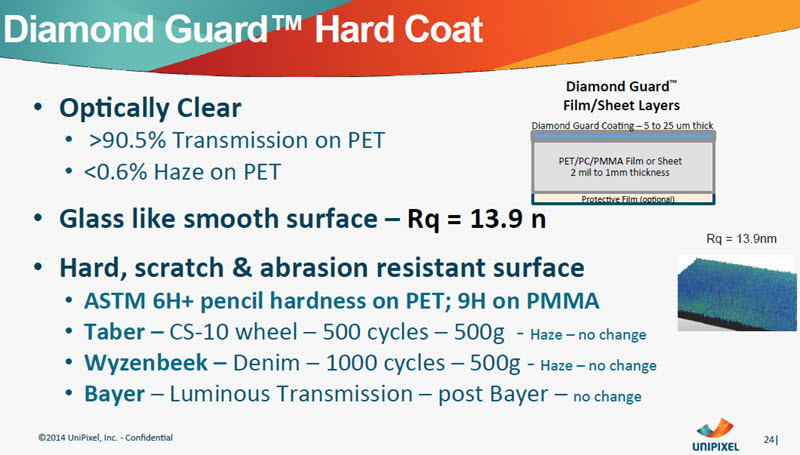

To meet the need to be flexible, the cover lens has to be very thin. Unipixel’s proprietary XTouch sensor pattern overcomes challenge of re-transmission, Shaik said. The company has also DiamondGuard resin material which can be used on the cover lens to increase hardness and abrasion resistance, while maintaining flexibility.

Shaik said the firm has tested displays over 200K bends at 2mm radius without any performance degradation in resistance.

Materials used for touch also need low haze and there other requirements.

The DiamondGuard material is said to be very optically clear with low haze (<0.6% on PET) and have tested for hardness to 6H+

DiamondGuard is said to be very optically clear.

DiamondGuard is said to be very optically clear.

In the panel session that followed the talks, Shaik said that touch is a problem when glass gets as thin as 0.4mm or using film at 0.2mm. Flexible will need thin substrates, although UniPixel believes it has a solution to this challenge.