We published, a couple of weeks ago, a press release from the developer of organic TFTs, Smartkem that announced that it has signed a Joint Development Agreement (JDA) with RiTdisplay, a Taiwanese company that is dedicated to OLED manufacturing. That’s an interesting development, so I caught up with Ian Jenks, CEO of Smartkem to get more background.

But first, as Arthur would say, a bit of background. Smartkem is a developer of organic TFTs that have better performance than amorphous silicon but that can be processed at low temperature but which can be deposited using existing amorphous TFT production lines. They can even be made on colour filter production lines, with a bit of extra sputtering equipment. That’s important because existing improvements on standard amorphous (A-si) transistors typically mean a switch to LTPS which is expensive and needs substrates that can stand a lot of heat as the silicon is re-crystalised or oxides which have proved much more difficult to bring into mass production than expected. Ian Hendy (as well as Ken and I) has written on Display Daily about other approaches such as those by Amorphyx, but it’s tricky to get the display industry to go in a new direction with new architectures. The Smartkem uses similar transistors to existing displays, but different materials.

Active matrix OLEDs need better transistors because as well as controlling the luminance of pixels, they have to pass the current produce the energy to create the image, unlike LCDs where the energy for the light comes from the backlight, so the transistor is just a controller or switch. Without an active matrix, you are limited in the resolution and performance that you can produce. Large LCDs use amorphous TFTs which are good enough for switching, but not for driving the right amount of energy for OLEDs.

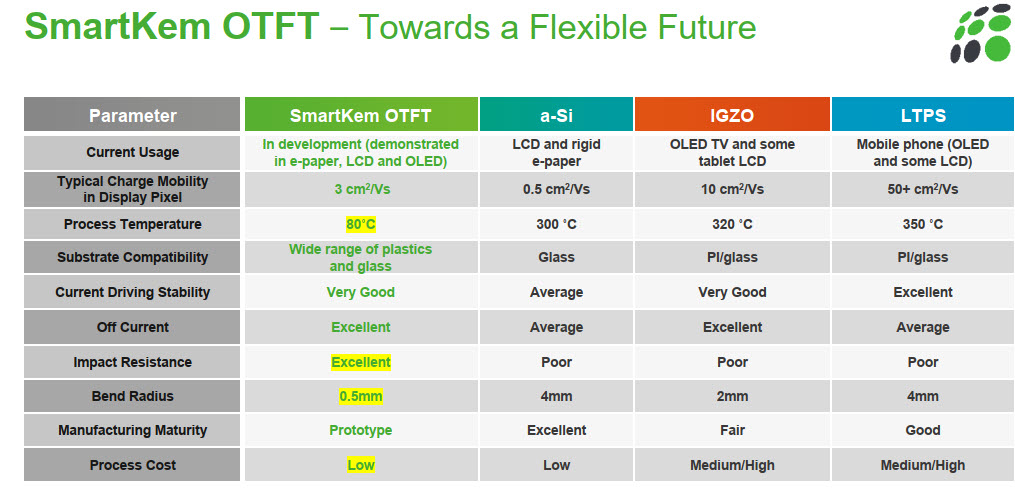

Bev Brown of Smartkem showed this chart at Display Week this year highlighting the Smartkem advantages

Bev Brown of Smartkem showed this chart at Display Week this year highlighting the Smartkem advantages

I remember seeing examples of OLEDs driven by amorphous backplanes created by AUO and as long ago as 2003, UDC showed prototype OLEDs based a-Si backplanes from AUO. However, the technology went nowhere as performance and stability were just not good enough.

RiTdisplay Has Focused on PMOLEDs

There is a market for passive OLEDs for small and low resolution displays and typically monochrome ones, and that is a market that RiTdisplay has pursued and developed. That is not to say that RiTdisplay has not been interested in AMOLEDs. We reported more than a decade ago that the firm was planning to develop AMOLEDs and in 2012 the firm showed an AMOLED using compensation circuits from Ignis Innovation. However, the project did not really develop and the firm focused back on PMOLEDs. It has continued to develop the technology and was the first firm to sign up to use the Kyulux TADF material.

Anyway, back to the deal. Jenks is, of course, enthusiastic. I can understand that. RiTdisplay looks to me to be a great partner for Smartkem as it has a clear idea of ‘what doesn’t work’ in AMOLED based on its previous experience. It’s also not one of the vertically-integrated behemoths that might be a bad mis-match in scale with a still small start-up like Smartkem. It also has access to good potential early markets for simpler displays than the high end flexible and rigid smartphones that are the bulk of the current AMOLED market. The Smartkem technology works well on very low cost plastic substrates because of the ability to be processed at very low temperatures. That’s appealing for two reasons.

First, there are plenty of people making devices that would love to have a low cost, robust, but higher resolution and full colour display. Think of the billions of smart devices and household appliances that could make use of such a display. The displays don’t have to be huge, but just better than the current solutions – and cheap. That’s the first kind of application that the firms are working on and there could be prototypes as early as next year, Jenks told me.

(Students of disruptive technologies will recognise the classic approach – do something cheap and simple to get you started with a business and to provide customers and experience to develop your business and technology! Jenks is a very experienced executive in a range of different high tech industries, so I’m not putting this approach down to luck! To find out more about his background, you might enjoy the interview I did with him around the SID CEO Forum this summer.)

(Students of disruptive technologies will recognise the classic approach – do something cheap and simple to get you started with a business and to provide customers and experience to develop your business and technology! Jenks is a very experienced executive in a range of different high tech industries, so I’m not putting this approach down to luck! To find out more about his background, you might enjoy the interview I did with him around the SID CEO Forum this summer.)

RiTdisplay has done work on smartwatch OLEDs and that is another potential application for the Smartkem transistors.

Adding Transistors to Existing OLEDs

It turns out that there is a second advantage of the low temperature processing. The Smartkem transistors can be processed onto an existing display as an additional layer without damaging it because of the 80°C processing temperature. So, you could take an OLED made using other technologies and then add organic transistors for sensor functions – for example to develop fingerprint sensors that cover the whole surface of the display. Other types of sensors can also be developed. There will be more from the firm about this in the future (and this article is already long enough!)

Driving LEDs

In our discussion, we switched topics. I was very impressed with what Smartkem has been doing to use its technology to create an active matrix for miniLEDs and microLEDs both for backlights and, later, for direct view. The technology has the advantage that the substrates that the transistors can be mounted on are extremely low cost. That means that where you have a ‘sparse matrix’ – a relatively high ratio of area between transistor clusters and the area of the transistors – the technology has distinct advantages.

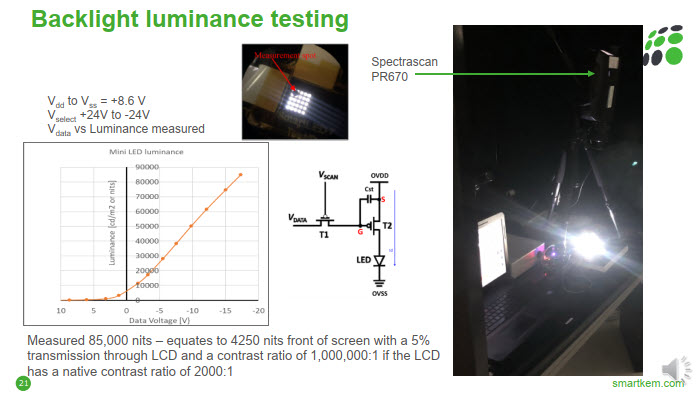

Smartkem showed this chart of backlight output – but we heard that the tests were pushed to even higher extremes

Smartkem showed this chart of backlight output – but we heard that the tests were pushed to even higher extremes

Jenks told me in the summer that the firm had been able to drive extremely high brightness from miniLEDs to allow the development of backlights using an active matrix. This time he told me that he has been working very closely with Dolby on aspects of HDR with an eventual aim of getting to displays with a surprising level of brightness of even above the 10K cd/m² of the PQ tone curve. Of course, you can do this using technology such as LTPS, but that is difficult and expensive for larger displays. Smartkem has been very impressed with the level of understanding of how humans and displays interact by Dolby and has a lot of interest in the work. He emphasised that Dolby is not looking to get seriously into the device business, but is still exploring HDR and vision with the aim of enabling future technologies. (BR)

Thanks to Smartkem for covering the cost of moving the article outside the paywall so that it does not use one of the free allowance.