Lutz Nehrhoff von Holderberg is from Barco where he looks after the control room business. He has been in Barco for twenty years. Barco has a new 24/7 control room projector using lasers (not laser phosphor, he said). This is for the critical infrastructure market particularly security and surveillance, traffic and transport. Barco also sells into applications in natural resources, automotive and universities as well as utilities and process control. Barco offers LCD, LED and rear projection cubes in these segments. Holderberg gave an overview of the strengths and weaknesses of the three technologies.

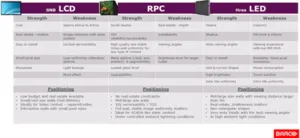

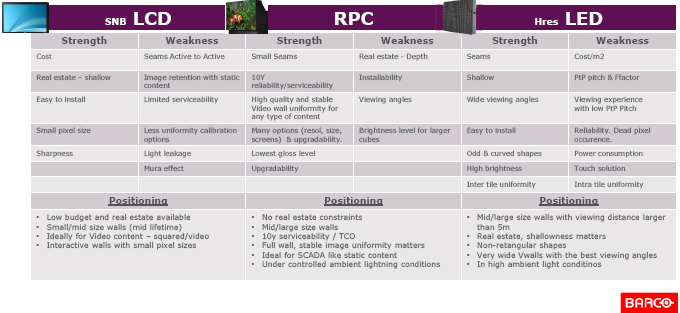

Barco’s control room displays analysis. Click for higher resolution

Barco’s control room displays analysis. Click for higher resolution

LCDs with very narrow bezels are popular and the cost is good per unit with installations often in 10s or 100s of units. Customers buy on a cost per m² basis. There is still a gap to other displays, but there is a declining gap. The weakness is the visible seams, with active to active image distances of 2.4 to 2.8mm and around 3mm once installed. (you have to leave a gap for thermal expansion – Man. Ed.)

A weakness is image sticking with often the same image shown for years. Brightness uniformity can be a problem and that can look like a seam from a distance. Fitting to a particular space can be challenging as LCDs are less flexible, they are only really available in 55″. You also may need to rely on software to scale character sizes. Light leakage can be an issue, round the edge of the panel or from gaps in the bezel. Mura effects can be poor especially in 24/7 applications.

Rear projection cubes (RPCs) have ‘no gap’ seams which allows a basically seamless view, although the depth of cubes can be an issue.

Long life is good for RPCs and 10 years is typical in the market. Viewing angles may be limited but are usually good enough. Brightness was difficult, but has been getting better.

Small pixel pitch LED solves the brightness issue and can be seamless, but it’s expensive at the moment. Holderberg surprised delegates at the event by saying that LED has ‘disappeared again from control rooms’ because of cost per m², after two years of activity (this was not echoed by any of the vendors that we spoke to on the show floor about this – Man. Ed.)

LEDs can be any shape and size, but are sometimes too bright and it is difficult to get good image quality dim because of the difficulty in the digital driving. Intra-tile uniformity can be difficult. The fill factor is tiny and Holderberg said that 1mm pitch is perceived as 1.3 to 1.5. Resolution to match RPCs and LCD is still a little way away. Dead pixels can be an issue with LEDs and these are simply not acceptable in some control room applications.

In summary, if budget is an issue, go LCD while RPC is a safe choice. LED is great for a ‘wow effect’. (sometimes what looks like a control room is not really a control room but a marketing feature!)

Laser light sources are an opportunity for innovation and Barco has been developing laser technology for a long time. The question was how to exploit it in this application.

Holderberg re-iterated the RPC benefits and added that if TCO is important, the technology often has the lowest TCO because of good power consumption. LED is currently the golden standard for RPV light sources.

However, laser can meet all the issues you need in RPCs. With lasers, you can double brightness and lifetime is good with 11 years uninterrupted use possible. The better matching to optics means a saving of 25% of power and you can get ‘library level’ noise. Because there are a lot of individual lasers, you get multiple redundancy and easy motorised alignment.

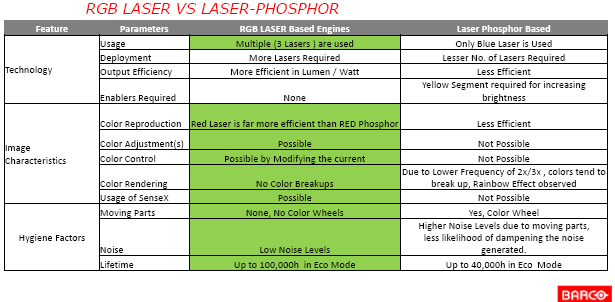

Barco looked at laser phosphor as well as RGB laser and Holderberg said that LP was to solve a lamp problem. However, RPC has been LED for five years. Matching of colours is difficult because of the yellow segment and therefore Barco went to an RGB modulating laser.

With this architecture, you get separation of light source and image generator. That means you can control the colour of the light source.

There is a desire in some markets for Rec. 709 support, which was not available in the industry, but Barco now has 170% of Rec 709 which means that you can select different smaller gamuts e.g. you can match 3500K for TV studio use.

The engine that Barco has developed uses 200W but produces 1600 lumens. Holderberg said that he ‘loves colornits’ (talked about by QD Vision DS18 QD Vision Proposes ColorNits, but seeing some criticism) as it reflects the typical 25% boost in perceived brightness from the HK effect. Etendue is the key to the system efficiency with lasers as LED has a challenge in coupling to the DMD. LP has some etendue issues and the laser means that optics get a lot smaller and cheaper.

But it’s not just about the specification, for example a big issue for how easy to install? The brightness also means that control rooms don’t have to be dark any more, which is popular with architects.

The lowe power consumption means it’s easier to make quiet displays and the cubes are in the ‘mid 30 dbs’ of noise. Holderberg said that Barco might not be ‘the laser guys’, but the cooling guys as the cooling has a big impact on the noise and life time.

In questions, Holderberg confirmed that the red and blue channels were generated by direct lasers, but green is still produced using phosphor conversion, but does not have a colour wheel, it uses a pulsed laser, but he seemed coy about details. (I was quite sure that he showed a graph of the spectral distribution which had narrow red and blue, but a relatively broad green, but this was not in the handout)

He also said that different RP screen technologies are enabled by the higher brightness available. Also in response to a question about relative pricing, he said that rear projection is double the price of LCD and LED is double the price of RPC.