Ken Li is from Wavien and he started by introducing the company. The company develops IP in displays, especially in lamps and light sources.

He talked about Wavien’s concept of putting laser-excited phosphor into liquid. Heat is an issue in laser-phosphor displays (LPDs) and liquid can help cool the phosphor. With careful design, you cold make inkjet-like phosphor cartridges allowing them to be easily replaced and providing an on-going income stream, while extending the life of the projector for customers.

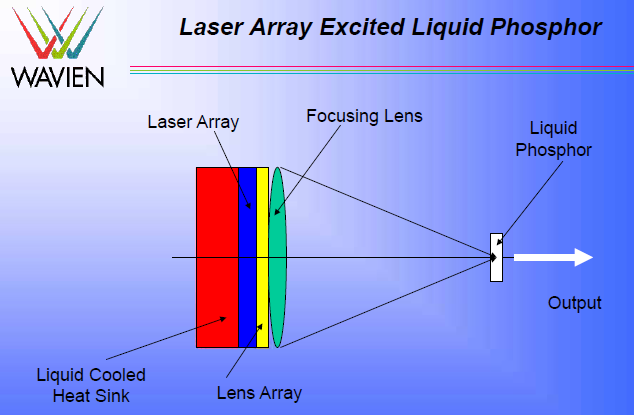

Wavien has designed a closed loop system using a peristaltic pump to move liquid. The system can make reflective or transmissive displays.

The company has tried different concentrations of materials and different viscosity mediums with a range of results. Adding the phosphor to the liquid is easy. Looking at the spectrum, you can get to CRI 82 with different phosphors, Li said. Mixing yellow and other phosphors gets you different spectrum spreads, depending on the application.

Reflective displays can use a heat sink. In theory, Li said, you could make a 600W 20 x 20 array from 1.5W lasers with collimating lenses to create a 600W laser that can focus onto the phosphor. Wavien has tested high power by simulating a high power density of 40/50W/mm². This is powerful enough to burn the phosphor, but is around ten times more than what you really need in practice. Liquid cooling stopped the burning in the Wavien tests. 30,000 lumens on the screen needs 90,000 in the correct etendue, Li said and that needs 180K lumens at the light source – which needs 600W of laser power. 600W of laser output needs 3KW of electricity.

In testing for temperature effects, Li said that up to 150º C there is no real problem with keeping phosphor working as it should.

Phosphor aging is well understood for electron-excited phosphor, partly because of the history of CRTs, but not really known for laser-excited materials and so more research is needed there. You could add dye to the phosphor to modify the colour performance, Li said, but it is probably not needed.

Wavien is looking for commercial partners who want to replace mechanical phosphor wheels with liquid cells. The company will offer exclusive licences for different imagers and systems.

For small systems, you could probably make a low power version with a piezo pump, Li said. This avoids the need for a motor for the wheel and doesn’t count as a mechanically driven system.

There was a question about whether you could make a QD version and Li said that you could.