Martin Chien is from Microlite Screen which has a new technology for projection screens for wide viewing angles. It is a new company, but Chien has more than ten years experience in screens.

Projection is the cheapest display technology per diagonal inch, but there are drawbacks because of the problems of ambient light. You really need a screen with increased luminance and high gain and with rejection of ambient light for successful projection. There is a gain and viewing angle trade-off with traditional projection screens. If you want high gain, you lose viewing angle. In an ideal world, the image would be the same wherever it is viewed from, and in any ambient light conditions. Also, all the details of the image have to be seen at all times, Chien said.

In the market now, you have to have special room setups to control ambient light. You can find screens with ambient light rejection, but you typically lose viewing angle, and there tends to be a loss of colour accuracy or an introduction of colour distortion.

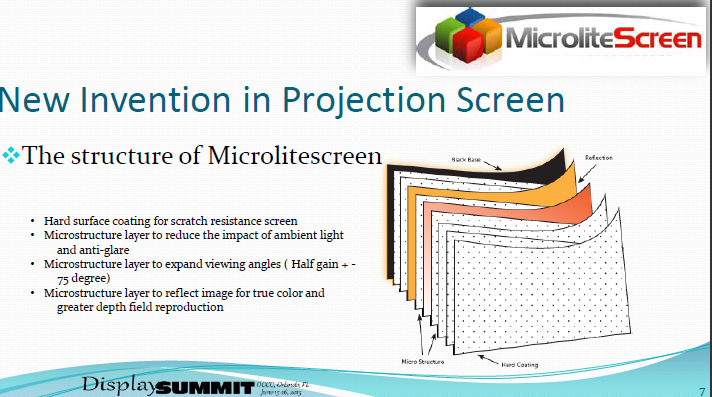

Microlite has developed a new technology – based on the question of whether you could use the ideas from the way an LCD works? With an LCD, you go through a number of films. Could you do the same with a screen?

Microlite took four years to develop the screen system – two to develop the concept and two to get to mass production. There is a hard coating on the outside of the film and inside are microstructure layers to reject ambient light, to increase viewing angle and to reflect. The half gain point is >150° – nearer to 160º, Chien said that the screen has 5 micron detail structures so even 8K is no problem – in fact, even 20K is possible.

Microlite is now ready for mass production and has five films developed, three for front projection and two for rear (two are specially optimised for rear-projection). The firm also said that it can make an “infinite series” of panels that can be arranged in an arbitrary pattern to create very large screens, although the maximum size without joins, currently, is 144″. The firm is capable of making 5,000 M per day (up to 500 complete screens) and is looking at wider microsculpture machines to enable wider displays.

The company will develop a range of different products with 16:9 fixed, motorised, no edge, portable pull up, curved and also a modular system to allow any size.

This kind of screen may be helpful for lower power projectors – even a 300 lumen would be OK for a 70″ and a 500 lumen projection would look OK on a 100″, Chien said. For 200″ diagonal, a 2K lumen unit would be needed.

In conclusion, the screen offers a wide viewing angle, speckle free images with full colour and ambient light rejection. In the future, the technology can be made with an R2R process so it is possible to cost reduce and in a couple of years could be as low as a matt white screen if there is enough volume.

In response to a question, Chien said that the maximum width is 1.9m wide because the micro sculpting machine has a maximum 2M width, but might be able to go to 3M. However, joints cannot be seen from more than 3M. The screen is not polarising preserving, so needs 6P or active technology for 3D.

For UST, there are two different versions, it’s not quite as good wide viewing angle but half brightness is >100 degrees.

Analyst Comment

We looked at the screen at the main Infocomm show. The screen was good, but we’re not convinced that it was rejecting light enough to radically transform the market. It would have been good to see the screen in better conditions at the Summit, but after the first day it was removed and that point we hadn’t got round all the demos! (BR)