Dyoptyka is a Dublin, Ireland-based company that makes deformable mirror systems that are designed to significantly reduce the amount of speckle in laser-based systems. Speckle reduction is important in laser-based displays and many other laser-based applications such as area illumination, microscope illumination, and interferometric optical systems. Speckle can be a problem in these systems regardless of whether the laser light is in free-space, fiber optics, light pipes or light guides such as the ones used in LCD backlights.

Dyoptyka has been around for about 10 years now. In 2015, they announced they were shutting down and selling of the company’s intellectual property. As Mark Twain reportedly said (but probably didn’t), “The reports of my death have been greatly exaggerated.”

Fergal Shevlin, founder of Dyoptyka and an Assistant Professor at Trinity College, Dublin, said about Meko’s story on the 2015 announcement:

“Your report accurately reflects our intention at the time [2015], having made insufficient progress towards commercialization of the technology. Our attempt to sell our IP/know-how resulted in several interesting conversations with prospective purchasers and some offers. However our analysis was that they undervalued the potential for our technology should higher power, higher efficiency, and lower cost laser diodes become available commercially at red and green wavelengths in particular. Therefore we decided not to sell, but to buy ourselves more time by further cutting expenditure. Three years later we have no regrets because great progress has been made by laser diode manufacturers. Consequently, there is renewed interest in our technology from prospective customers.”

Shevlin was the author of an article on the Dyoptyka technology titled “Phase randomization for spatiotemporal averaging of unwanted interference effects arising from coherence,” published as an open-access paper in the August 1, 2018 issue of Applied Optics. A pre-print of the article can also be downloaded from the Dyoptyka website. This article describes the technology of the deformable mirror and gives examples of speckle reduction in a variety of applications.

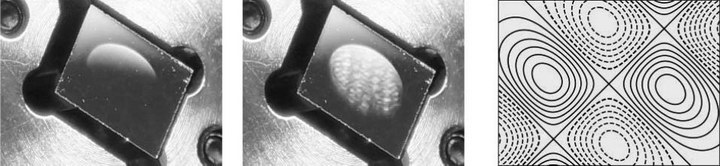

[Left pair] Small deformable mirror in inactive and active states. Elliptical central region is 3 mm× 4.5 mm. [Right] Contour plot of simulated surface wave heights with solid contour lines above the static plane and dashed lines below it. As heights change over time the curvature of each region is reversed. (Credit: Dyoptyka)

[Left pair] Small deformable mirror in inactive and active states. Elliptical central region is 3 mm× 4.5 mm. [Right] Contour plot of simulated surface wave heights with solid contour lines above the static plane and dashed lines below it. As heights change over time the curvature of each region is reversed. (Credit: Dyoptyka)

The Dyoptyka deformable mirror is a very thin membrane with a reflective coating on it. This membrane is driven by piezoelectric actuators to set up surface waves in the coating, as shown in the figure. The deformable mirror in this example is actuated at hundreds of kHz to excite randomly distributed surface deformations for angular divergence without diffraction losses. Reflection efficiency is approx. 99% and damage threshold is approx. 6 W. Power consumption depends on application requirements but is typically ≤100 mW. Dyoptyka has made devices as large as 40mm x 50 mm for use in laser-illuminated projection displays. This device could handle more than 100W of visible light optical power.

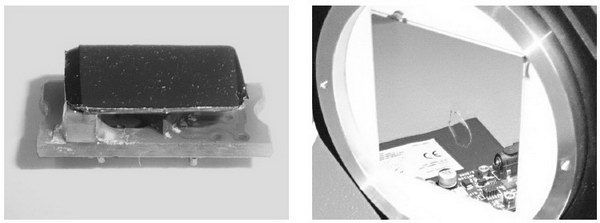

Left: 3.0 x 4.5mm elliptical active area deformable mirror with integrated electronics. Right deformable mirror with a 40 x 50 mm aperture for use in a projection display.

Left: 3.0 x 4.5mm elliptical active area deformable mirror with integrated electronics. Right deformable mirror with a 40 x 50 mm aperture for use in a projection display.

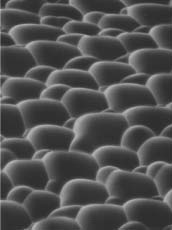

The contour plot of simulated surface wave heights shows smooth transitions between regions of convex and concave curvatures. In conventional diffusers, such as the ones used in moving-diffuser speckle reduction systems, there are abrupt surface angle changes between adjacent diffusing elements. These abrupt changes cause diffraction that can significantly reduce the efficiency of the system by diffracting some of the light out of the optical path.

Surface structure of an RPC Photonics Inc. engineered diffuser. Although it is smooth piecewise, its slopes are discontinuous such that diffraction occurs. (Credit: Dyoptyka)

Surface structure of an RPC Photonics Inc. engineered diffuser. Although it is smooth piecewise, its slopes are discontinuous such that diffraction occurs. (Credit: Dyoptyka)

According to Shevlin, the piezoelectric activators do not just set up a standing wave pattern in the deformable mirror. When I asked him about standing waves in the membrane, he said:

“You are correct about any fundamental modes of vibration excited in the surface: they are periodic standing waves. As such they are not good for the generation of uncorrelated speckle patterns over time so they are not good for speckle reduction. Therefore we developed a proprietary excitation strategy that results in a superposition of travelling and standing waves that are much more random in their spatial and temporal distribution.”

He added that these pseudo-random surface deformations provide much better speckle reduction.

At any given instant in time, a deformable mirror will produce a speckle pattern. For display applications, the human eye/brain combination averages a very large number different speckle patterns over a time period of 10s of milliseconds, a very long time compared to the hundreds of kHz of the mirror vibration speed, largely eliminating visible speckle.

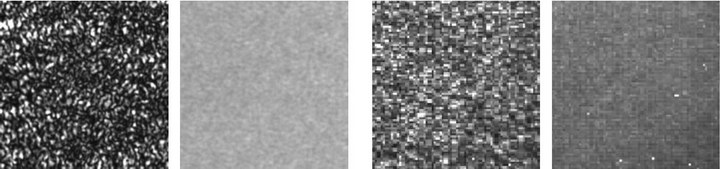

[Left pair] Semiconductor wafer inspection microscope image with 213 nm (DUV) laser illumination. [Right pair] Thermal infrared sensor calibration system image with 10.6 μm (LWIR) laser illumination. [Both pairs] Speckle (left) is reduced (right) by the deformable mirror. (Credit: Dyoptyka)

[Left pair] Semiconductor wafer inspection microscope image with 213 nm (DUV) laser illumination. [Right pair] Thermal infrared sensor calibration system image with 10.6 μm (LWIR) laser illumination. [Both pairs] Speckle (left) is reduced (right) by the deformable mirror. (Credit: Dyoptyka)

The Dyoptyka technology works over a very wide range of wavelengths, including the complete visible range, as shown in the image. The reflective coating and other properties of the deformable mirror need to be adjusted to accommodate different wavelength ranges.

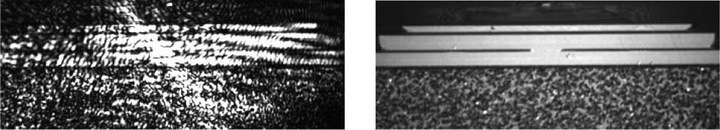

Magneto-optical Kerr microscope image of a magnetic storage disc recording head, with illumination from a 445 nm laser diode (Credit: Dyoptyka)

Magneto-optical Kerr microscope image of a magnetic storage disc recording head, with illumination from a 445 nm laser diode (Credit: Dyoptyka)

In addition to the reduction of speckle caused by CW lasers in display applications, the paper also presents data on speckle reduction on pulsed lasers and in systems where the detector has a much shorter integration time than the human eye. This is shown in the image where the imager integration time was 1mS. The paper also presents data showing speckle reduction from a speckle contrast of 40.7% to 5.5% when the imaging is done with a single 1µS laser pulse.

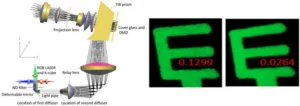

Left: layout of a laser-based DLP Picoprojector. Right: Speckle with the deformable mirror off and on. (Credit: National Chiao Tung University)

SID 2018 Paper 63.1 from National Chiao Tung University shows the speckle reduction in a laser-based DLP picoprojector using a Dyoptyka deformable mirror. With the base-line combination of non-moving diffusers tested and the deformable mirror turned off, speckle contrast for the system was 13.0%. With the mirror activated, the speckle contrast was reduced to 2.6%.

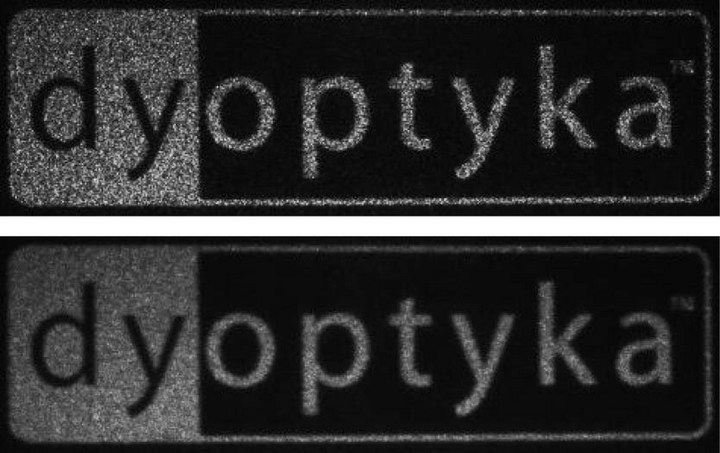

Holographic image of the Dyoptyka logo formed by a Jasper Display Corporation LCoS microdisplay with 1920 × 1080 pixel phase modulation. Speckle with the deformable mirror turned off (top) is reduced (bottom) by activating the deformable mirror (Credit: Dyoptyka)

Holographic image of the Dyoptyka logo formed by a Jasper Display Corporation LCoS microdisplay with 1920 × 1080 pixel phase modulation. Speckle with the deformable mirror turned off (top) is reduced (bottom) by activating the deformable mirror (Credit: Dyoptyka)

True holographic displays are a particularly difficult speckle challenge because a holographic display depends on the coherence of the laser beam to form the image. If the coherence of the illuminating beam is completely destroyed, there is no image. Typically this results in a lot of speckle in the holographic image. While the Dyoptyka technology does not eliminate this speckle, it does visibly reduce it, as shown in the image.

While the lifetime of the deformable mirrors is not specified, Shevlin said in his recent article:

“The only moving parts are piezoelectric actuators and sensors rated by their manufacturers for 100,000 h lifetimes, and the surface of the deformable mirror. We have not undertaken accelerated lifetime testing, but we do have devices active for over 50,000 h without failure. Our understanding is that the amplitude of surface motion is within the elastic limit of the material such that mechanical fatigue does not arise, as with MEMS resonators.”

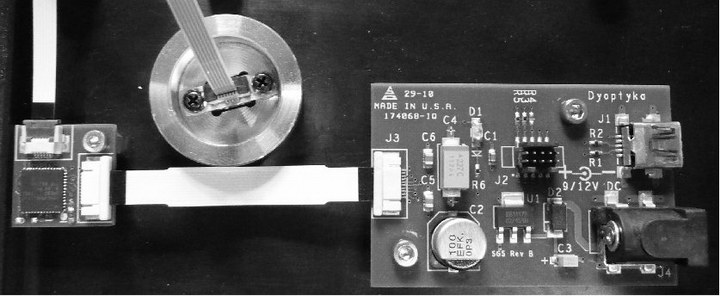

Dyoptyka evaluation system comprising a deformable mirror with application-specific size and coating, reconfigurable control electronics, and PC-hosted reconfiguration software. The circle on the upper left is the back of the mirror casing and the mirror itself is not visible. In this example kit, the deformable surface area is 4.5 x 3.0 mm² (elliptical) within a rectangular area of 7.0 x 5.0 mm². (Credit: Dyoptyka)

Dyoptyka evaluation system comprising a deformable mirror with application-specific size and coating, reconfigurable control electronics, and PC-hosted reconfiguration software. The circle on the upper left is the back of the mirror casing and the mirror itself is not visible. In this example kit, the deformable surface area is 4.5 x 3.0 mm² (elliptical) within a rectangular area of 7.0 x 5.0 mm². (Credit: Dyoptyka)

The company provides development kits and optical system design consultancy services for its deformable mirrors to potential customers. A sample development kit is shown in the image. When Shevlin was asked about these kits, he replied:

“We try to supply whatever sizes and coatings the customer needs for their application. Sometimes this requires the design and manufacture of special configurations. Because nearly every application is different and requires different configurations of deformable mirror and different levels of support, I’d rather not publicize any specific pricing. However it is absolutely in our strategic interest to help customers undertake evaluations so we try to keep the price barrier as low as possible.”

–Matthew Brennesholtz