I make no apology for returning to a 20 year topic in the display industry, blue for OLEDs. Blue has often been a challenge for displays and optical devices because of the high energy needed to create blue light. Famously, it took many decades to create and commercialise blue LEDs and efficient deep blues have also been a long challenge for OLED makers.

Although blue has been created (indeed, Samsung’s QD OLED relies mainly on blue emitting materials), it has been very hard to get efficient output. For those that have not been watching what has been going on, there have been several different generations of OLED materials.

These are

- Fluorescent materials that enabled full colour OLEDs with red, green and blue but with 25% of the theoretical maximum emission giving an EQE of around 7%

- Phosphorescent materials that should be able to achieve 100% emission in red (2010-12) and green (2013), but with blue, so far, missing as a commercial material. Phosphorescent can provide around 22% EQE

- TADF materials which are also much more efficient than fluorescent. TADF materials in red and greeen are just becoming available, but blue is not quite ready, yet. These materials could achieve more than 22% EQE.

- Hyperfluorescence, which is seen as an extension of TADF but with better properties. The technology is said to be lower cost than phosphorescent, with narrower band emitters and high efficency

- Plasmonic phosphoresence – a future highly efficient and valuable material system, but still in the R&D stage. Barry wrote about this last week (The Next Generation of OLED Emitters Could be Plasmon PHOLEDs)

When the materials are at very different levels of efficiency, some engineering needs to be done to ensure a balance of colours that is suitable for the application. In the case of OLED technology such as WOLED, you have to balance the colours to some extent to create white and then ensure that the colour filters are matched to the light emitted to ensure balanced output. In the case of an RGB or side-by-side OLED, you need to balance the pixel sizes to get a good white. That typically means a structure that is not the same as a simple RGB stripe that you might see on an LCD, for example.

The use of different pixel structures then needs to be taken into account when creating images, especially text. Samsung has the ‘pentile’ structure in its RGB OLEDs to get the performance that it needs. In the case of its recent QD-OLED, there has been some controversy over whether the pixel structure it has chosen is optimal for text use.

Anyway, at Display Week, we heard from a number of companies in the industry about their developments.

- UDC is the leading supplier of materials and ip for emitters and confirmed that it is still on track for commercialisation of its blue phosphorescent material in 2024. As we said when the news first became public (An Inflection Point on Blue OLED Materials), this is a big deal. OLED was already doing well in the market, continuing to grow as LCD is faltering. and phosphorescent blue is a big, big jump for the technology. Still, there was no really new information from the firm at the event.

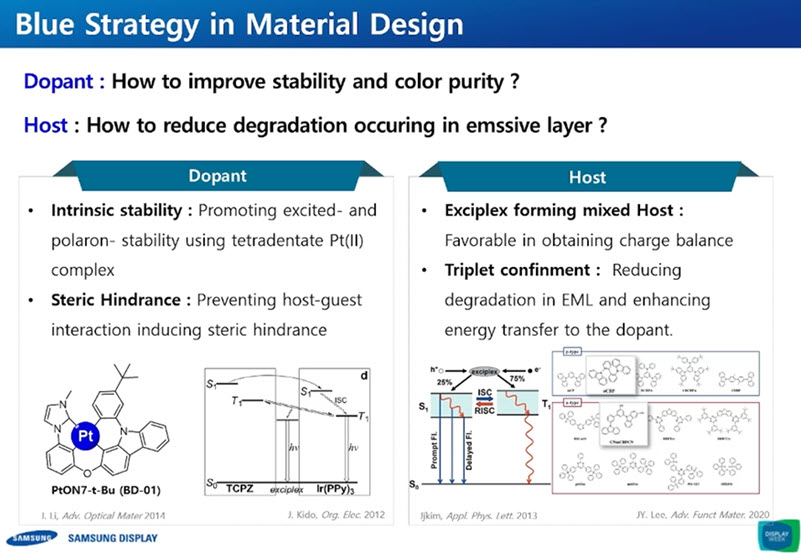

- Samsung spoke about what it has been doing to develop longer blue lifetimes for TADF and phosphorescent materials. Dr Sunghan Kim gave an oral presentation (no paper) #40.2 (A paper was published in Nature Photonics last year). As well as better materials, he emphasised the importance of light coupling. He covered the importance of the dipole emission of light and that a fast radiative decay rate leads to high performance. The firm tried to develop phosphorescent materials with a sharper spectrum than fluourescent materials, based on platinum complexes. In lifetime, there have been few publications recently and little progress in recent years. He pointed to the microsecond scale decay time of phosphorescent materials (and TADF) in comparison to the nanonsecond decay time for fluorescents. Stability and colour purity have not been possible at the same time. The Nature Photonics paper showed a 10X improvement in lifetime, with a short decay time and increased colour purity.

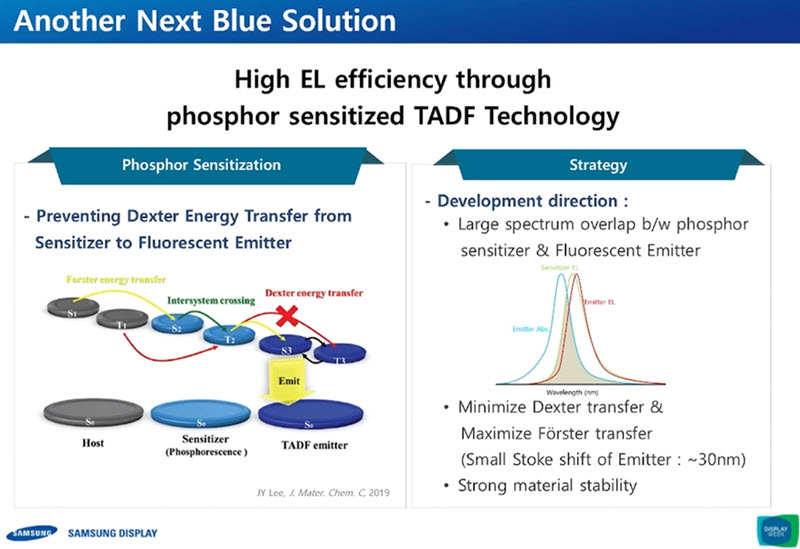

- Samsung is still working on a new material system with a new concept to minimise Dexter transfer and maximise Förster transfer. In questions, he admitted that bringing the <0.2 blue CIE y value that was achieved down to <0.1 caused challenges in lifetime and he said that the group is also working on another approach.

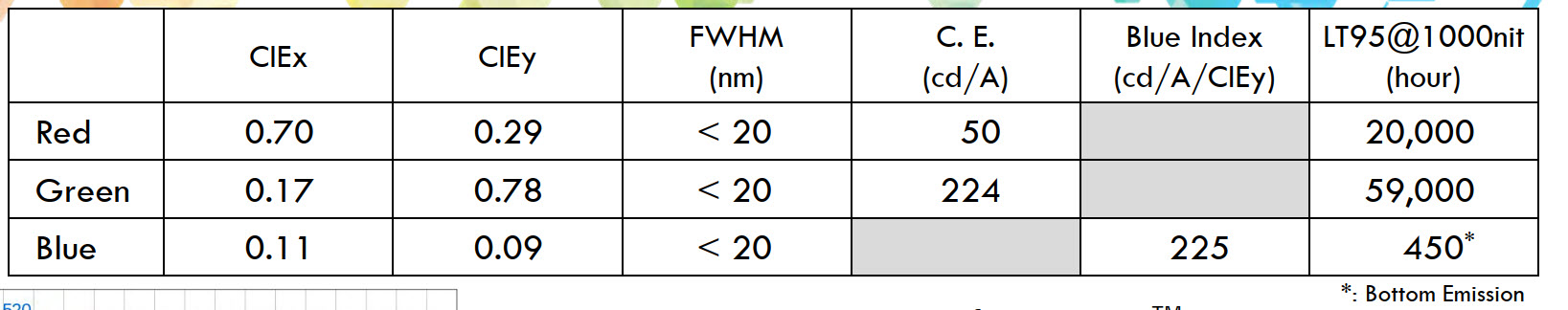

- Kyulux gave an update on its TADF material and hyperfluorescent material. The firm gave details of where its materials have got to as part of the virtual SID/DSCC Business Conference and although it’s blue is still short of the target lifetime for commercialisation, Jun Aduchi from the firm said that by the end of this year, he is confident that the firm will reach the target of T95 of 750 hours for his new blue material, which was at 250 hours a year ago and 450 hours now. That sounds like a very short lifetime, but typically display material life is quoted in terms of its lifetime to 50% emission, rather than 95%. Although some applications need very long lifetime in the tens of thousands of hours, there are many important ones, such as smartphones, wearables and automotive, where much shorter lifetimes are acceptable. Like UDC, Kyulux expects full mass production of blue in 2024 and the material is based on TADF with a fluorescent dopant. Red is very close to commercialisation and materials can have FWHM of <20 nanometres which allows wide colour gamut with a choice of colours for P3 coverage or to give more of Rec.2020. Green materials will be commercialised in Q3 of this year.

- Noctiluca covered its business model but we covered that recently here (Noctiluca Sets Out Its Stall for Advanced OLED Materials)

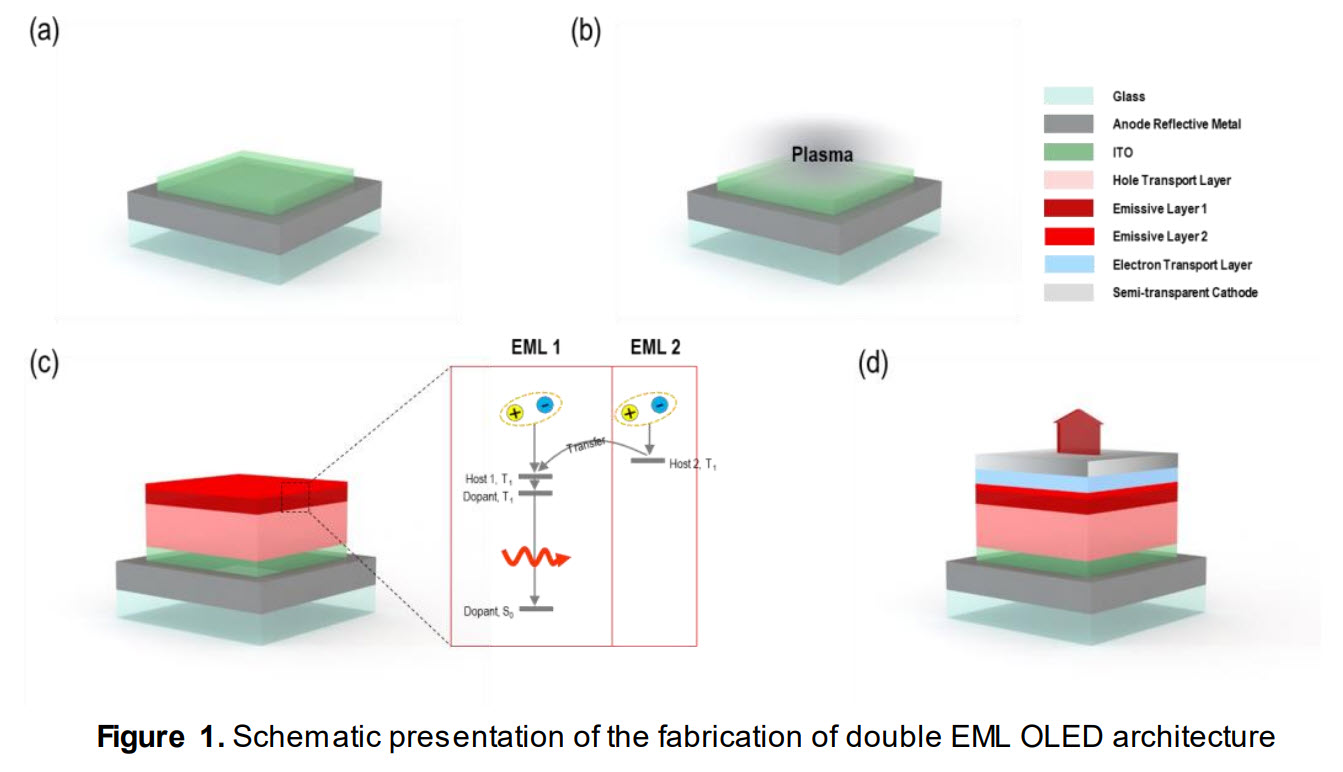

- Idemitsu of Japan presented a distinguished paper on its work to get Fluorescent blue materials to a level of around double the typical EQE of blue emitter materials by using a TADF-like dual emitting layer and optimising the light extraction. Doing this achieved 14% EQE, the paper reports. Realization of ultra-high-efficient fluorescent blue OLED

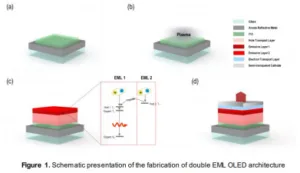

- LG Display gave a paper explaining how it had achieved nearly a 5% improvement in EQE by using a dual emitting layer – Double EML Structure for High Efficiency Organic Light Emitting Diode – 40.4 EH-Lee

I often say that what you don’t see can be as interesting as what you do see. I couldn’t help noticing, this year, the absence of German researcher, Cynora, which originally was ‘laser-focussed’ on blue TADF materials, but when the runway to develop the materials seemed to be stretching away, pivoted to start to try to commercialise other colours while it developed blue in the background. The company launched a development green TADF material in January 2021, but as far as I can see, did not present or exhibit at Display Week. No doubt the firm was there ‘in a back room’ somewhere! (BR)