For more than two decades, OLED has had a particularly big weakness. Like other LEDs, it has always had challenges with producing blue light. But OLED material maker UDC may have made a significant breakthrough.

It’s over two decades, since I made myself ‘persona non grata’ when an OLED developer in the UK held a very hyped press conference to talk about ‘rollable TVs on your wall’ and I asked a question “What about blue? When will you be able to make blue pixels?”. To be fair, the scientists at the firm were trying hard to understand the needed semiconductor mechanism that could have the energy gap to create blue light. But it has been tricky.

For those that might be new to OLEDs, there are two classes of emitter materials used in OLEDs. The first class are fluorescent materials. They were the first materials to be developed for OLEDs, but they have the disadvantage that they are not very efficient as only around 25% of the singlet excitons can be harvested and without clever optics, only around 5% of the power comes out as usable light (EQE).

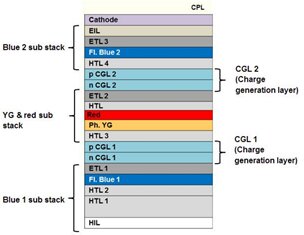

A much more efficient approach is to use phosphorescent materials which can access the other 75% of excitons as well and can get the overall efficiency to over 20%. As long ago as 2003, we reported on the challenges that material developers were having making phosphorescent blue materials. OLED display makers have to use phosphorescent red and green materials and fluorescent blue. That means that they either have to use extra layers of blue or pixel designs that are weighted to give more area to blue materials to get balanced light for video applications.

LG’s OLED Stack of several years ago. Source:IHS

LG’s OLED Stack of several years ago. Source:IHS

It’s not that nobody has tried and there has been a lot of effort put in to solve the issue by the leader in supplying technology and materials for the emitter materials, UDC, and by start-ups like Kyulux, Cynora and Noctiluca as well as chemical companies including Sumitomo, Samsung SDI, DuPont, Idemitsu, LG, Merck et al. Academics have been heavily involved too. Much of the development has been in the field of TADF materials. (TADF Is the Future of OLED, but the Future Comes Slowly) (and there was some interesting work on new blue materials published in Nature Photonics from the Sungkyunkwan University published last year in Nature Photonics)

As well as TADF materials, hyperfluorescence has been a topic of research by Kyulux and Cynora. (An Update on Kyulux Hyperfluorescence Technology and What’s a Kyulux?)

We have often reported ideas and ‘breakthroughs’, but still materials didn’t come to market. I remember hearing UDC, responding to a talk by, I think, Cynora at an industry event where the US company pointed out that the three critical attributes of correct colour, lifetime and brightness/efficiency were interlinked and that while you could optimise one to make a good colour, a bright display or one with a long lifetime, it was very hard to optimise even two of those to the levels needed for commercialisation. Three has been beyond anybody so far in terms of blue.

I remember a conversation with Barry Young, CEO of the OLED Association and a Display Daily contributor, saying to me years ago at Display Week. “Make sure that they tell you lifetime, colour and brightness in the same test if you want to believe that someone has a good material” (or words to that effect – it was a very long time ago!).

(for a deeper dive into the topic of OLED development, check out this ‘Brief history of OLEDs‘. At 24 pages, it’s not that brief but if you are really interested in the chemistry it’s a great resource!)

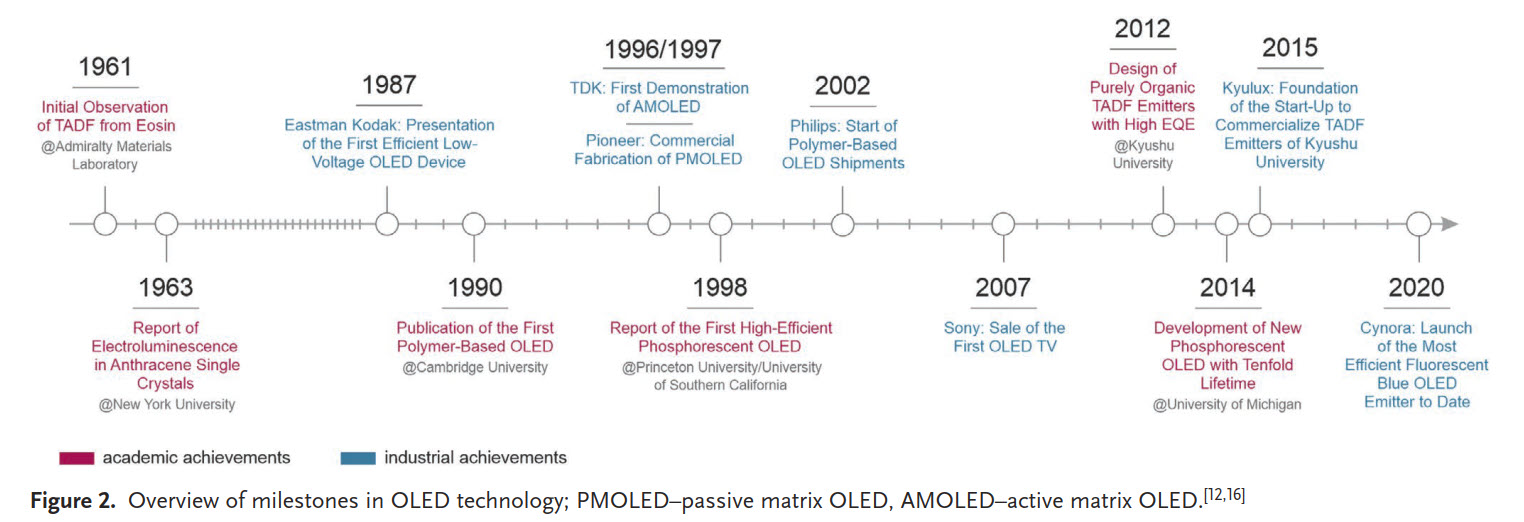

The referenced history includes this timeline.

The referenced history includes this timeline.

Brightness and lifetime might be well understood but colour is perhaps a bit less obvious. It has proved particularly difficult to make deep blue OLEDs. As a result, display makers have come up with innovative solutions. For example, LG’s WOLED, used in all the currently shipping OLED TVs at the time of writing, adopted a dual blue layer strategy using a light blue with better efficiency and lifetime most of the time and with a separate deeper blue layer with weaker efficiency and lifetime.

Where’s the Beef?

So, after all that preamble, what’s the big news? Well, in their quarterly analyst briefing, UDC finally gave an update on their phosphorescent blue developments. Up to now, the firm has said that ‘progress is continuing’ but has given no clue or hint as to when it might come into the market. However, this week the firm said that it would meet some ‘target specifications’ by the end of this year and with potential commercialisation by 2024. That’s a big change and given that UDC is a profitable public company in a very litigious world, if it says this publicly, we can reasonably assume that it is extremely confident that it can achieve what it says.

Of course, that probably doesn’t mean that it can meet every target of every client and application. Initially it may be limited to, for example, watches which would benefit from the efficiency but may be less sensitive in terms of colour than TV applications need and may have less lifetime or brightness needed for a tough application such as automotive. However, that we have got to this point is really good news for the future of OLED and bad news for alternative display technologies.

However, I do see this announcement as very significant for all OLEDs and, especially, the idea of QD OLED that Samsung has been developing. The whole of the performance of that device depends on the blue OLED material that is the key emitter. Samsung is a big long term customer of UDC, so it would be surprising if the companies had not been in talks about this development for some time! (BR)