The subject is emitting materials for OLED displays. Let’s review.

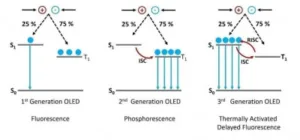

What are now called first-generation materials were (and are) fluorescent emitters. Without troubling you with molecular quantum mechanics, these materials eventually create a maximum of one photon for each four incoming electrons. That’s an internal quantum efficiency (IQE) of 25%. Since not all of the photons make their way out of the material to the viewer’s eyes, the external quantum efficiency (EQE) is less than that. In other words, a fluorescent OLED is an inefficient device. On the positive side, materials scientists were able to make red, green, and blue fluorescent emitters that had the right color coordinates to make displays with a good color gamut.

With a lot of work, materials scientists managed to access the phosphorescent emission modes, which produce a maximum of three photons for each four incoming electrons (75% IQE). And then they learned to move access both modes at the same time for 100% IQE. But there was a problem. To this day, only the green and red phosphorescent OLED emitters have color coordinates suitable for a good color gamut. The phosphorescent blues that UDC and others have been able to make that are otherwise suitable are light blue, not the required deep blue. So, today’s OLED displays — both for cell phones and for TV sets — use a phosphorescent red and green along with a fluorescent blue. The resulting devices are reasonably efficient, but an appropriate high-efficiency blue emitter remains the ‘holy grail’ of OLED materials.

Fig. 1. Emission systems of the first three generations of OLED materials. (Figure: Edinburgh Instruments)

Fig. 1. Emission systems of the first three generations of OLED materials. (Figure: Edinburgh Instruments)

Along Come TADFs

Several years ago university laboratories developed materials called TADFs — for thermally activated delayed fluorescence — which was another way of harvesting both the fluorescent and phosphorescent modes, but made the universe of possibly appropriate molecules much larger.

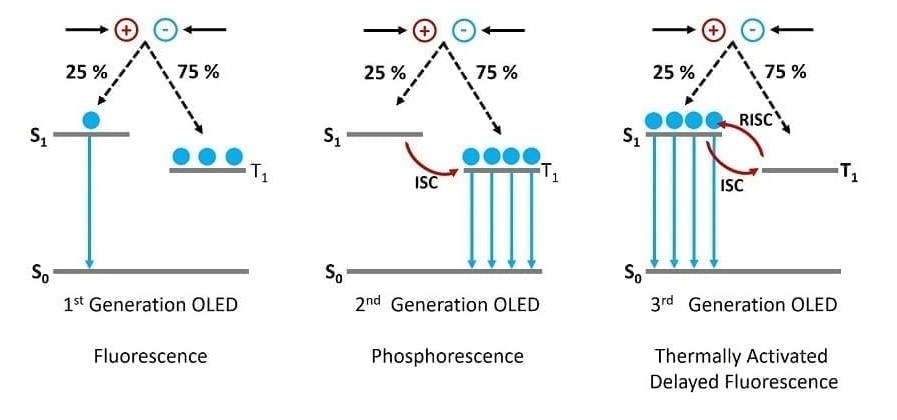

Hyperfluorescence is another way to harvest all four photons that produces a narrower emission spectrum, that makes the universe of possible materials even larger, and makes the quest for an efficient deep blue more likely.

The two prominent companies developing practical TADF and hyperfluorescent materials are Cynora (Bruchsal, Germany) and Kyulux (Fukuoka, Japan). In previous Display Dailies I have concentrated on Cynora because Cynora has been far more forthcoming in their papers concerning the detailed characteristics of their materials — particularly blue — and what remains to be done to satisfy customer requirements.

Fig. 2. Characteristics of the four generations. (Figure: Kyulux)

Fig. 2. Characteristics of the four generations. (Figure: Kyulux)

Kyulux is Serious

But I think I leaned too far in Cynora’s direction. Kyulux may have frustrated me with their lack of transparency (and booth personnel who were unable to present a compelling story), but it is a serious company. Allow me to make up for my neglect in the next few paragraphs.

Kyulux’s hyperfluorescence technology is based on the research of Chihaya Adachi and his group at Kyushu University. (Adachi is a co-founder of the company.) Kyulux acquired an exclusive license in 2015. Currently, the company has 70 employees.

In late 2019, Taiwan-based WiseChip Semiconductor launched the first commercial hyperfluorescent display, using a Kyulux hyperfluorescent material. (The display was and is a 2.7-inch, 128×64, yellow passive-matrix display. A WiseChip photo shows the new display next to its much dimmer fluorescent predecessor (Fig. 3). (An Update on Kyulux Hyperfluorescence Technology)

Fig. 3. WiseChip’s passive hyperfluorescent OLED display (left) is 2.5 times brighter than its fluorescent OLED predercessor. (Photo: WiseChip)

Fig. 3. WiseChip’s passive hyperfluorescent OLED display (left) is 2.5 times brighter than its fluorescent OLED predercessor. (Photo: WiseChip)

I could not find any mention of green or blue developments on the Kyulux website*. Cynora announced in January the availability of test kits for TADF deep green emitters, and is selling a fluorescent blue emitter with 15% greater efficiency than conventional blue fluorescents. Cynora said it discovered this material while searching for a blue hyperfluorescent material.

Back to the WiseChip display and a couple of questions. What was WiseChip’s reason for using the Kyulux material instead of UDC’s phosphorescent yellow? Is the greater color purity important in WiseChip’s application? Is UDC’s cost structure too high? Or is it simply that Kyulux and WiseChip have been development partners for several years?

Kyulux and WiseChip: I would be happy to incorporate your answers in a future Display Daily. (KW)

Ken Werner is Principal of Nutmeg Consultants, specializing in the display industry, manufacturing, technology, and applications, including mobile devices, automotive, and television. He consults for attorneys, investment analysts, and companies re-positioning themselves within the display industry or using displays in their products. He is the 2017 recipient of the Society for Information Display’s Lewis and Beatrice Winner Award. You can reach him at [email protected] or www.nutmegconsultants.com.

Editors Comments

*Last year at SID, in the conference proceedings and in the Business Conference, Kyulux talked about its green materials (An Update on Kyulux Hyperfluorescence Technology). We reported news about Kyulux blue developments published in Nature in January 2021. Hyperfluorescent Blue OLED Points Way to Pure and Efficient Blues (BR)