Ayataka Endo, a member of the research team at Kyulux Inc. (Fukuoka, Japan), presented an invited paper during the recent SID Displayweek conference that reported the latest progress on the company’s HyperFluorescence (HF) OLED technology. The article associated with the presentation is contained in the SID 2020 digest on pages 57 – 60 and is entitled “Innovative Technological Progress of Lifetime in Hyperfluorescence.” A copy of the article can be found here.

First, a little background information.

Thermally Activated Delayed Fluorescence (TADF) molecules are a type of material often used in OLEDs. These materials are typically electro-luminescent and emit light having a broad spectrum. This last characteristic is not desirable for display applications. Displays need to emit red, green and blue light that have a narrow spectrum in order to produce images that have a wide color space.

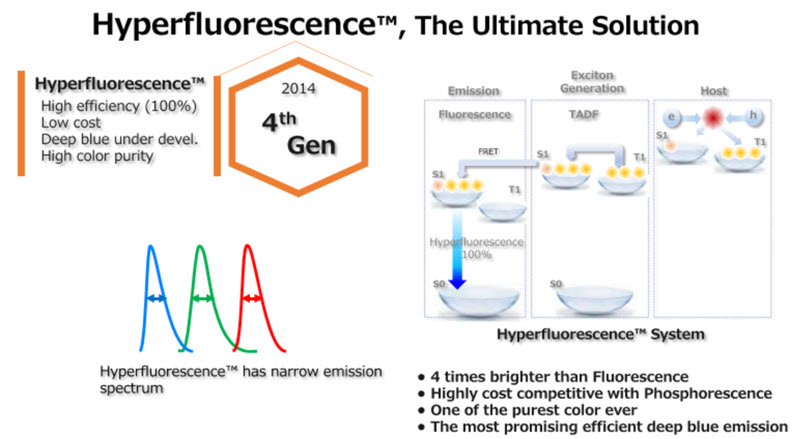

To address this issue, Kyulux has developed an approach based on compounds that produce what the company calls HyperFluorescence (HF). HF is created by combining TADF materials with fluorescent materials.

Source:Kyulux – SID/DSCC Business Conference

Source:Kyulux – SID/DSCC Business Conference

The mechanism by which HF produces light can be explained by paraphrasing the article. In HF, TADF molecules acts as an exciton generators and transfer excitons to fluorescence molecules by a mechanism called Förster Resonance Energy Transfer. FRET describes energy transfer between two light sensitive molecules or chromophores. A donor chromophore, initially in its electronic excited state, may transfer energy to an acceptor chromophore through nonradiative dipole – dipole coupling . The fluorescent molecules receive and emit light with nearly 100% internal quantum efficiency.

To put this value into context, the emission efficiency of HF is almost four times that of fluorescence alone. In addition, this level of efficiency in HF is achieved with a very narrow emission spectrum and without the use of any expensive rare metals such as iridium in the HF molecules.

At this time, a yellow HF emitter material has been commercialized in PMOLED applications. The product is a result of collaboration between Kyulux and WiseChip Semiconductor Inc. (Chu-Nan, Taiwan). The display using the yellow HF achieved a brightness that is 2.5 times that of an exclusively fluorescence based display using the same fluorescent material as the emitter.

At the conference, Kyulux reported that the company’s red and green materials are “close to commercialization.” The company also reports improving the color point and lifetime of its HF blue emitters . A table summarizing the latest performance specifications of HF materials is presented below.

Performances specifications of various HF devices.

Performances specifications of various HF devices.

The researchers attribute the lifetime improvements of the blue HF to a proper combination of TADF assistant dopant and a fluorescence emitter. They note, however, that further development is required for blue to meet color and lifetime requirements needed for all commercial applications. HF is also reported as having achieved a lifetime that is sufficient to allow use of these materials in small and medium size AMOLED display applications. More specifically, the lifetime improvement of the yellow, red, green and blue devices compared with previously reported results (May 2019) were 5.6 times, 14.2 times, 4.0 times and 2.1 times respectively .

The lifetime of a red TADF device was improved by moving and enlarging the charge recombination zone toward the hole transporting side. Finally, a so-called co-host device structure was applied to the HF devices and was found to improve the initial as well as lifetime performance.

The article concludes with what is clearly an opinion. That is: hyperfluorescence is the next generation of emission system in OLEDs based on highly efficiency, pure color and the potential for a lower display cost based on reduced material costs. – Arthur Berman

Analyst Comments

In his comments at the DSCC/SID Business Conference, Kyulux CEO Jun Adachi said that the target for the blue emitter material, needed for a commercial customer, is 700 hours (T95). He hopes to achieve this ‘in the next year’, although he also conceded that another breakthrough may be needed and we have heard this kind of forecast several times over the years from OLED material developers. That’s why UDC is so cagey about when it might have a breakthrough on blue. (BR)