Back in August, Yole ran a webinar that looked at miniLED with Eric Virey from the firm and Eric Li from Silicon Core, someone I am always happy to catch at trade shows – he always has something interesting and useful to say.

The (free!) registration was still available when we went to press if you want to listen to the whole thing.

Eric Li – Top Left, Eric Virey, bottom left

Eric Li – Top Left, Eric Virey, bottom left

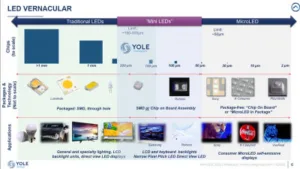

Virey started the session by covering LEDs in general including looking at definitions of microLED as well. He also highlighted that there is no real definition of miniLED. After describing how an LCD works, he described full array local dimming (FALD) and summarised the haloing issues that you get with local dimming. Increasing the number of zones improves things and that is where miniLED comes in as better than FALD by having more zones. Yole tries to define miniLED sets as having 1,000 zones or more but some TV brands are claiming to be miniLED with just ‘hundreds of zones’.

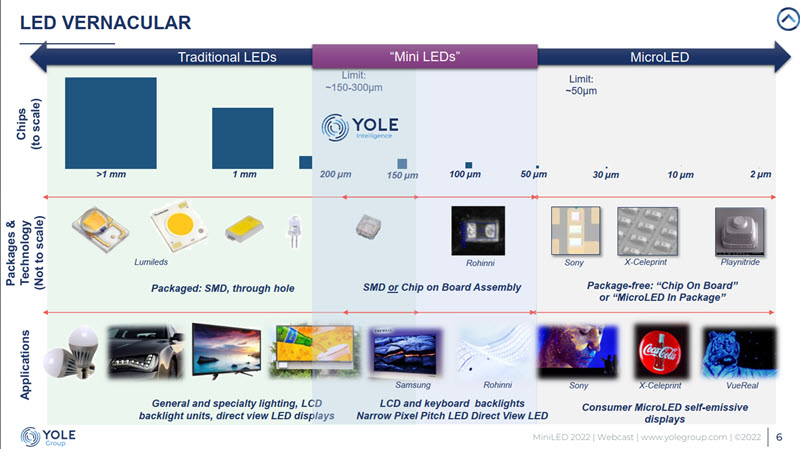

Virey showed the results of the tests that Yole did with dxomark on the iPad Pro and that we covered in a previous Display Daily (Everybody Knows MiniLED has Bigger Halos than OLED, Don’t They?). There are many different design decisions to be made in choosing a miniLED architecture, so there are many different options and alternatives. He pointed out that Samsung has 1344 zones with 12K LEDs, but they needed to use 8mm spacers to distribute the light and also use 100’s of driver chips. On the other hand TCL has 1920 zones, and uses 96K miniLEDs, but this means that it does not need to use spacers and also is able to use passive matrix driving. However, despite the lack of drivers, TCL’s backlight costs 60% or 70% more on an area basis.

At the moment, designs are ‘all over the map’, but Yole expects some convergence in the future for TVs to around 2K zones with 5K to 20K LEDs. TCL, for example, between 2021 and 2022 kept the same number of zones, but dropped the number of LEDs by almost a factor of 10 at the expense of an increase of 5mm in thickness.

There are many opportunities for cost reduction in miniLEDs with many areas available to reduce cost by, for example, combining multiple films to single specialised films. Vertical integration and competition will also drive costs down. In the supply chain, the miniLED dominates the cost of the panel but requires much less capital so there are many players in the market.

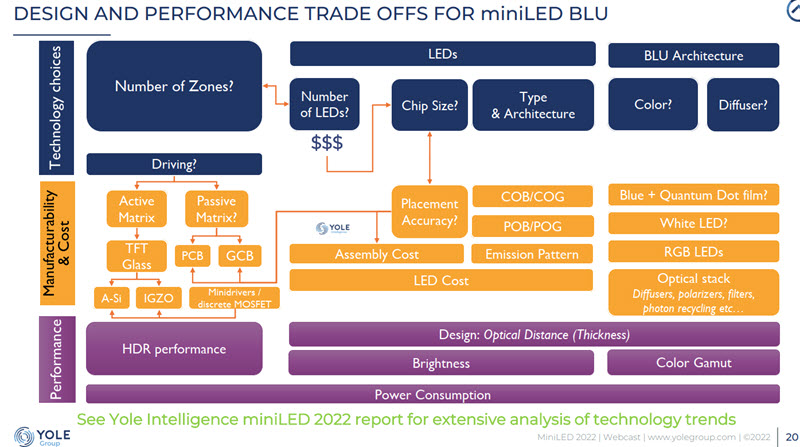

MiniLED is competing in TV applications at the high end with OLED by focusing on large sizes and 8K. MiniLED should have more opportunity to cost reduce, so the technology should be able to move down to the mainstream in the longer term.

In IT, adoption is increasing with new fabs for G6 and G8 for IT applications and if all fabs come to fruition, there could be 10X growth, although it will be unlikely that all fabs will go ahead. OLED manufcaturing is also increasing in capacity and performance and that will mean a squeeze on the potential market for miniLED.

Overall, Yole expects a big boost to miniLED backlighting but with less growth than if OLED was not around. Monitors and automotive miniLED displays should grow. I terms of LED size, die size is likely to stay at around 200 x 200?m for notebooks and tablets while TV will be around 150 x 500?m. COB is likely to be adopted in the high end, moving to the lower end and there is little incentive to move to glass and away from circuit boards.(BR)