Tanaka Kikinzoku Kogyo, said to be the leading Japanese company for precious metals developed in conjunction with Dr. Tatsuo Hasegawa from the University of Tokyo, AIST Flexible Electronics Research Center and Yamagata University a method to create a ultra fine wire metal mesh substrate that can be used for touch screen applications in flexible displays.

So far Indium Tin Oxide has been the solution of choice, however the brittleness of low resistance layers limits the useful bending radius. Metal mesh deposited on plastic substrates was a possible solution, however the deposited line width was not small enough to create a invisible metal mesh layer.

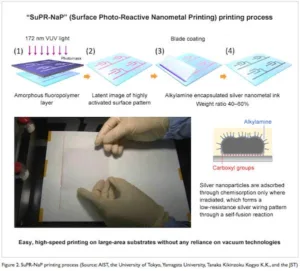

This new method is using silver nanoparticles that are ‘printed’ on the plastic substrate and then sintered at a temperature of 80º C. The ‘printing’ process is using a chemisorption process of coated silver nanoparticles on activated surface patterns created by a laser process.

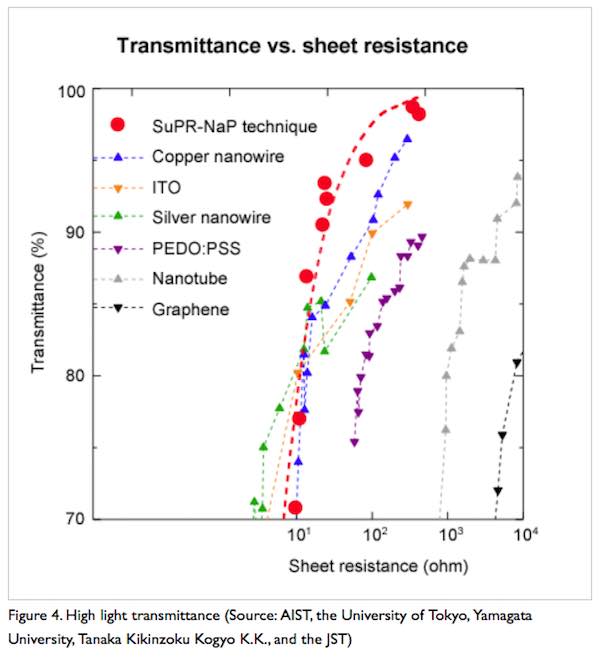

The process has produced some of the highest sheet resistance combined with optical transmittance, as is shown on the following graph. The smallest achieved line width was in the order of 0.8 micrometer. They also tested against resistance to repeated bending and found that at a benign radius of 5mm the properties remained mostly stable up to 10,000 cycles. At 3.5mm radius they saw a decrease in sheet resistance, which they attributed to a breakdown in the plastic substrate itself.

Tanaka company provides a more detailed explanation of the process in an article on their website, together with a YouTube video showing the process and the results in more detail. The process lends itself to a R2R process, which should make it very cost effective if the used materials can be manufactured at a competitive cost. NH