AlphaDisplay of Korea was at the show to highlight, in particular, its developments in medical displays. To help promote that vertical segment, Alpha has recruited from fellow Korean company, Kostec, which is a specialist in medical displays. Alpha already has a European facility in Sofia, Bulgaria, and is opening another in Bratislava, Slovakia in Q1 2017. Bratislava will focus on industrial and transport applications, while Sofia concentrates on gaming displays.

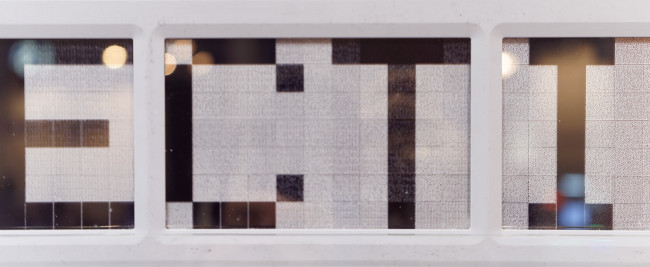

AUO was represented by a distributor, Best Electric Display (BED) that was showing the P320XVF03 V0 panel which is a 31.5″ 1366 x 768 panel that is transparent. Based on AHVA (normally black), the panel has 3,000:1 contrast and wide viewing angles. Transparency was not quoted, but it didn’t seem very high to us.

AUO’s transparent display. Image:Meko

AUO’s transparent display. Image:Meko

DKE is a key player in the e-Paper business. It is a Chinese maker of devices that supplies (among others) Pricer and SES Imagotag and it also has its own technology and patents in both EPD and in cholesteric LCD. The company works with E Ink in Taiwan. The company has developments in ‘true colour’ ePaper that it is aiming, initially at IoT applications. The company sees three key applications for EPD (E Ink) technology. The first is Electronic Shelf Labels and the second is smart cards. The company had an example of a smart card with a display and DKE told us that it sees a big market in China for this technology. The third market is smartwear which is growing very rapidly. As well as these markets, DKE is active in smart meters for industry use.

Although we couldn’t get full details, DKE told us that its Trucolor technology uses a combination of EPD and cholesteric technology with ‘combined cells’ (as far as we could understand, this means that part of the cell is an EPD pixel and part is cholesteric. The technology is said to be ideal for indoor advertising, but might struggle over a full temperature range outdoors.

We reported on Etulipa in a Display Daily a few weeks back (Etulipa Developing Electrowetting for Public Display). This was the first time that we were able to get ‘up close and personal’ with the display which is designed for, relatively, low resolution low power displays and is based on electro-wetting technology. Looking close up revealed a lot more about the structure which uses a lot (400) of very small (0.5mm x 0.5mm) individual cells to make up a single pixel. Part of this is to ensure that the response is fast enough, as the speed of an electrowetting display is dependent on the size of the cell.

We had been very impressed with the level of black in the images that we saw when we wrote about the technology and this turned out to be the case ‘in the flesh’. However, the small patterns in the cells do mean that the white is not as bright as, for example, an E Ink display. On the other hand, contrast is plenty good enough for the kind of signage application that Etulipa is aiming at initially. One questioned we asked was about the temperature range and we heard that the display should operate down to around -20º C and up to 50º. Etulipa was on the stand of United Radiant Technology of Taiwan, which is developing a mass production facility for the technology.

Evervision is a division of Everlight that specialises in industrial displays and offers the general added value technologies such as bonding and touch. The company has design and engineering facilities in Germany to allow fast customer support and flexibility with small miniumum order quantities.

Futaba was showing small passive OLEDs that were being used in wearables and viewfinders. The company also had a ‘smartkey’ concept for a car that included a 0.9″ display. The company also had a range of VFDs that it continues to ship in some volume.

InnoDisplays had what it called a circular display with 960 x 960 resolution on a 21.6″ diameter and apparently having ‘zero bezel’. However, when we enquired, we found that that the unit is actually rectangular and had been fitted with a circular mask. It looked good, but not quite what it seemed! The company also had a convex 640 x 240 6.2″ ‘cut’ and curved display for gaming machines.

Harvatek is a Taiwan-based LED packaging company that makes a lot of the LEDs sold by other companies including a big German one, but we couldn’t tell you the name, or someone would get in trouble. (Hint, when at a trade show, before you start giving away ‘secrets’, check who you are talking to! Man. Ed.) The company was joined on the booth by Apix, which is a Taiwanese LED display maker that uses Harvatek devices and was showing a 1.2mm LED display with 1,000 cd/m² and using a ‘miniCOB’ architecture. The company also makes 1.667, 1.875 and 2.5mm cabinets with 1,200 cd/m² (after calibration) for the two wider pitch designs. The 1.667 and 1.875mm pitch cabinets are under development. As well as installation products, Apix makes rental types. Apix tends to focus on OEM/ODM sales.

The miniCOB architecture from Harvatek puts a 2 x 2 array of LEDs on a single circuit board which is said to make the final display more robust, a real advantage in rental and staging. The array is easier to fix and also is said to improve cooling.

We’ve caught up with Tianma at a number of shows this year, from CES to Mobile World and SID. Although it has been shown before, we looked at the 5.46″ flexible OLED that the company has developed. Resolution is 720 x 1280 and brightness is 350 cd/m², with 10,000:1 contrast. The firm quotes a bending radius of 20mm and operating temperatures from -20º C to +60º. Another interesting panel is a 5.5″ 2560 x 1440 LCD panel for smartphones intended for VR that uses an LTPS backplane to allow a frequency of 90Hz and response time of <6ms. Brightness is 400cd/m² and contrast is 750:1 while colour gamut is quite wide for a mobile panel at 68% of NTSC.

Truly Semiconductor of Hong Kong was at the show and is another that is developing its active TFT-based display technology, having started with passive displays. As well as LCD, the company is developing AMOLED in the 5.5″ to 5.7″ range. On display was a 5.68″ AMOLED with 1080 x 1920 resolution (388ppi). It was showing new panels that will be used by companies such as Asus and Huawei.

Truly Europe has been established to offer local manufacturing to meet the needs of the automotive and industrial markets. One of the facilities available in Europe is a coating process for Truly’s ODLC ‘Diamond-Like Coating’ which is carbon-based and is coated onto the display lens before fitting to the device.

Another development is a ‘fingerprint under glass’ detector. This is designed because mobile phone designers are moving to concepts where the whole front of the phone is a display. That means that there is no space for a separate fingerprint detector, so Truly has one that can be fitted behind the display.

Finally, we looked at a new 12.3″ display that the firm has designed for automotive applications. It has 1920 x 720 resolution and 1000 cd/m² of brightness. Contrast is 1,000:1 and colour performance is claimed at 70% of NTSC with 24 bit support. Truly can also supply modules for automotive up to 15.6″ diagonal.

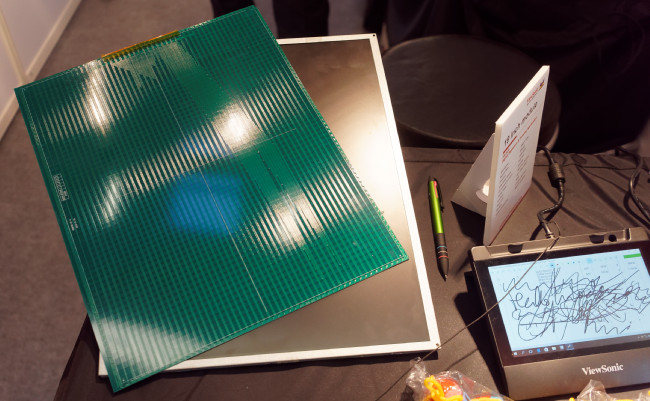

ViewSonic was showing the latest version of its stylus technology, which was originally developed with Hanvon. The company was at Electronica to show a new 19″ 5:4 module that can be used for signature capture. As we have previously reported, the ViewSonic tracking is high quality. Making components is a new business for the firm but it is making sensors and modules. Applications for the senors include ‘video teller machines’ (VTMs) which are becoming popular, as they allow a consumer to use video to talk to a member of staff at a bank. The company told us that there is a new EU regulation, eIDAS, that is designed to give approved electronic signatures the same status as paper signatures and ViewSonic can meet the requirements of this standard.

Although we have reported on Chinese OLED pioneer, Visionox, we haven’t had many chances to talk to the company, but we took the opportunity at Electronica. The company has been making passive matrix OLEDs since 2012 and claims to have been the largest supplier by volume and value in 2013 and 2014 and by volume in 2015. It hopes still to be top in 2016 on both parameters again. The company has new lines that are currently in ramp up and should get to full production in 2017. The company is building a 5.5G line for AMOLEDs and aimed at mobile phones. Its capacity is fully occupied, with a capacity of around 0.5 million panels per month, but this should increase to 1.5 million per month by the end of 2016 as the firm has a new G6 line with a capacity of 30K substrates per month. Visionox represents the industry in China and is helping to develop new standards for rigid and flexible OLEDs.