It’s a strange thing about the display industry that many successful technologies are based on what seem like very strange concepts. When I used to give training courses on display technology, first people were surprised by the high voltages, potential X-rays (and related lead shielding) and sensitivity to the earth’s magnetic field that was involved in CRT technology. The explanation of how an LCD works also surprised many. However, one of the least likely often seems to be electrowetting.

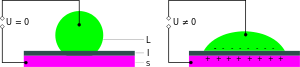

The basic idea is that based on the property of liquids, that the surface tension is changed by the application of a voltage. Change the voltage and you change the tension. Change the tension and you can change the shape of a drop of liquid. The liquid can block or modify the colour of light, so can be used as a display element. It uses little energy, was fast(ish), could be flexible and could create colour, so looked a good prospect for portable and battery-driven applications.

The basic idea is that based on the property of liquids, that the surface tension is changed by the application of a voltage. Change the voltage and you change the tension. Change the tension and you can change the shape of a drop of liquid. The liquid can block or modify the colour of light, so can be used as a display element. It uses little energy, was fast(ish), could be flexible and could create colour, so looked a good prospect for portable and battery-driven applications.

There have been a couple of developments using this concept. In 2003, Johan Feenstra and his colleagues showed work from Philips Research on electrowetting. That work was spun out in 2006 as Liquavista in Eindhoven, the Netherlands. I saw the company regularly at SID and thought it was making good progress. The company was bought in 2010 by Samsung and then in 2013, it was bought by Amazon and still has a web page, but hasn’t been seen in public for a while (although in February of this year, it was reported to be developing manufacturing technology in China. It has also been showing adverts of the joys of working for Amazon (August 2015). Of course, Amazon’s Kindle business has a big need for low power displays, but currently uses E Ink (electrophoretic) displays.

Other work on electrowetting was done in Germany, by Liquids in Motion GmbH (which has now stopped development), on displays with big pixels and by The University of Cincinnnati and by Extreme Photonix (which gave up in 2005) in the US.

Hans Feil with a demo unit. Image:Etulipa

Hans Feil with a demo unit. Image:Etulipa

Now we have news of another developer, Etulipa of Eindhoven which, as we reported last week (Etulipa Announces Cooperation with United Radiant Technology in Taiwan), has just done a deal for manufacturing with United Radiant Technology (URT) of Taiwan after four years of R&D ‘below the radar’. Given the geography, it’s no surprise that founder, Hans Feil was once at Philips Research and Liquavista. He founded Miortech as a spin off of Liquavista in 2006 and, among other things, developed an automotive mirror technology with Itri of Taiwan, and based on electrowetting, although this has not developed to production.

Second Generation Electrowetting

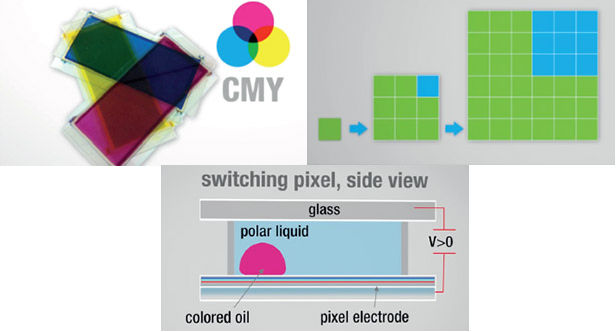

Etulipa says that its technology is based on ‘second generation’ electrowetting which is said to have two distinct advantages over the Liquavista approach. Etulipa told us that one of the problems with the Liquavista approach is that the base of the display has to be hydrophobic. Unfortunately, that means that it turns out to be difficult to manufacture the walls for each pixel on that kind of surface. Etulipa puts the electro-wetting cell walls on the opposite surface, typically an ITO covered glass surface. This allows usage of standard LCD processing steps to create the requested cell structures with very high yields.

Secondly, in this second generation electro-wetting display architecture the cell walls extend from the superstrate to the hydrophobic substrate in the display. In this way, Etulipa told us, they automatically function as spacers. This sub-millimeter spacer-structure is said to lead to a very solid and robust display (and electrowetting displays can suffer from interference from physical shock).

The Application

Unlike Liquavista, which has shown work mainly towards mobile devices, Etulipa saw interest from companies in outdoor displays and identified (but not to us!) key potential users in the US that saw an opportunity and have invested in the firm.

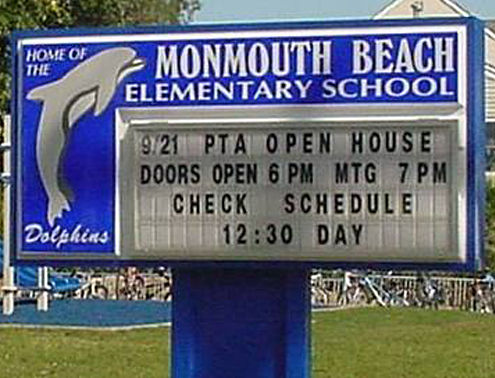

The key application that Etulipa is initially working towards is “changeable copy” boards. This is the kind of sign so often seen outside stores, churches and public buildings in the US (and a gift to Photoshop jokers!), have the disadvantage that they are not yet digital. They have to be low cost, and work well in high ambient light conditions.

Image: signsplussigns.com

Image: signsplussigns.com

Although LED displays are also a potential solution, there are obvious disadvantages in the cost of power and less obvious ones, such as a concern in many areas about light pollution. This kind of board does not need to be very high resolution and eTulipa has developed a modular tiled approach based on 12 x 8cm panels with 10mm pixels. The panels could be bigger in the future. Contrast and colour saturation can be good although initial products will be monochrome.

Etulipa is operating under an ip licensing model and manufacturing and module sales will be handled by URT and shipment is expected to start shipping in Q1 2017.