(Etulipa from Amsterdam would have been a better title, but to be accurate the song probably should have been Tulips from Keukenhof and that doesn’t scan!) I have been following the technology of electrowetting for nineteen years since Philips produced a paper in Nature that explained the concept. Developments from that original research have continued and the technology has got to (another) interesting point through Dutch developer, Etulipa.

The idea of electrowetting is that you can change the surface tension of a blob of liquid with a voltage. That causes the blob to flatten. If you put a reflective surface behind the blob, you can make a display and by varying the voltage fast, you can achieve ‘video compatible’ frame rates. The promise of a low power fast colour display was very attractive. The best looking low power reflective display is from E Ink, but, whatever the firm says in its press releases, suitable for video it is not as it is much too slow.

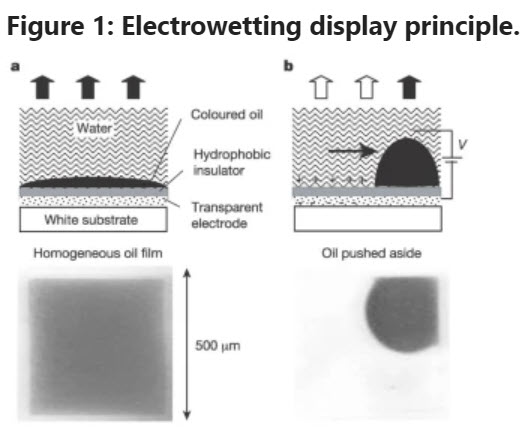

The electrowetting original concept from the Nature paper.

The electrowetting original concept from the Nature paper.

Philips spun off the technology in 2006 as it dropped its interest in displays and the vehicle for the further development of the technique, Liquavista, was purchased by Samsung. At the time, there were some really interesting demos at Display Week and with the backing of a display technology giant, there was a lot of optimism about the potential. However, quite quickly Samsung sold it back to its executives around 2013, and it was then bought by Amazon. However, Amazon also decided not to continue with the technology. Electrowetting seemed over.

Etulipa Sprouts

In 2016, we heard of another company, Etulipa and in 2016, I wrote about the firm’s technology and its plan to enter production, with a partner in Taiwan, to make a version of a ‘Copy Board’ – a popular feature in the US for publicising events. A few months ago, I set up a reminder to re-visit the technology as there seemed to be some interesting developments and it finally reached the top of my to-do list when the firm released news of a new display. On the back of that news, I had a chat with Hans Feil, CEO of the firm. As two veterans of the display business, our chat roamed over many areas, but I have heavily edited it to focus on the news!

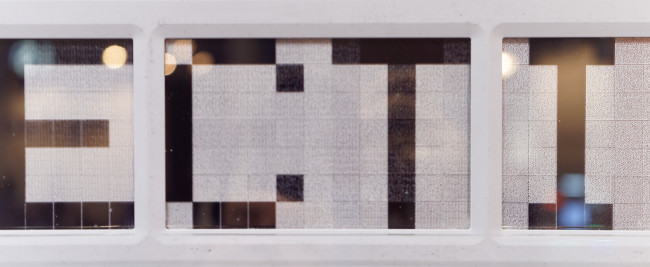

I took this picture of an Etulipa prototype on the Radiant booth at Electronica in 2016. Image:Meko

I took this picture of an Etulipa prototype on the Radiant booth at Electronica in 2016. Image:Meko

Feil explained how he first saw the electrowetting technology at an internal Philips Research demo a couple of decades ago. As I had already written about the development up to the point of the idea of the ‘Copy Board’ and as this looked like a real and promising application, I started by asking what had happened with that initiative? Feil explained that the idea hit a couple of snags early on. First, the size of the characters in the original design of display was simply too small. The US is a big place and for drivers to read this kind of copy, it needs to be big.

The second objection to the technology was the lack of colour. Although traditional copy boards were monochrome, users really didn’t want to replace them with a monochrome device. So Etulipa needed to make the displays bigger and support colour, although there was clear interest in the application.

In particular, one of the firms that saw an early prototype of the technology was Daktronics of the US. That firm has been a solid supporter of Etulipa and is a major shareholder.

The big announcement is that the company has a demonstrator of the technology concept based on larger tiles (10″ or so). At the moment, the tiles use direct driving, but there is a roadmap to boost that to 21″ active backplanes. Pixel sizes are 10mm and the droplets can be adjusted to eight sizes, so there is some greyscaling available, albeit with a limited (3 bit) depth. Each pixel can have three colour layers of cyan, magenta and yellow to give a full colour range.

The new version has good colour saturation

The new version has good colour saturation

What is the range of colours supported, I asked? Feil said that his team has struggled so far to find a good way to characterise the colour performance is it is so dependent on the light falling on the display. However, the colours can be reasonably saturated. One of the limits of the technology is that the pixel cannot be too high, front to back, so getting the layers just right at the ‘sweet spot’ takes some engineering.

The feedback from the firm’s demonstrator is that one of the appealing aspects is that the display is not too ‘in your face’. It gets a message across without potentially distracting from the scene.

There remain challenges in consistently achieving high uniformity and the next target for Etulipa is to scale up and automate the production process more as, for now, the TACT time is too long for commercialisation. The firm also only has a pilot line and making a lot of displays is tricky. It is planning to work with partners in Taiwan and the target is to be able to make 10s of square metres by the year end. However, to really drive the market it needs to be able to make at least that level every week.

Environmental testing is another hurdle that has to be overcome. The technology works at very low temperatures, and when Dakota had a very cold spell, a test was made to see what would happen. At very extreme temperatures of -25 deg C to -40 deg C, Feil told me, “you get some very interesting effects”. At high temperatures of 60 deg C or above, getting the right materials in the optical stack, such as adhesives, to work well can be challenging. As Feil told me, “There’s no point in scaling up without known reliability” and for a small group the testing can take a lot of time.

So, the latest version can now meet the key requirements of colour and bigger modules. Feil explained that he has had a number of interested parties to see the latest demonstrator in Eindhoven and I am trying to work out the logistics of getting there myself to see the technology. Going to see Etulipa in Eindhoven (BR)