Following the report by Matt on the launch of the Barco Unisee, we still had quite a few questions about the technology, so we jumped at the chance to interview Chris Sluys, who is VP Operator Experience of Barco. He joined the company to work on the control room side of the business from MMD where he ran the Philips LFD business. However, Barco is being very cautious about data that it is revealing, so although we enjoyed the chat, we didn’t get much information about the product that Matt hadn’t dug out!

Following the report by Matt on the launch of the Barco Unisee, we still had quite a few questions about the technology, so we jumped at the chance to interview Chris Sluys, who is VP Operator Experience of Barco. He joined the company to work on the control room side of the business from MMD where he ran the Philips LFD business. However, Barco is being very cautious about data that it is revealing, so although we enjoyed the chat, we didn’t get much information about the product that Matt hadn’t dug out!

We asked about the panel details – for example how does Barco avoid the asymetric bezels that normally hide the column and row drivers? No comment. How does the panel get held together if the edge material does not have a clamping role? No comment. Are the drivers integrated into the panel? The panel is a custom unit, that is assembled with the backlight at Barco’s own factory in Taiwan, but no more details of the panel. If there is no bezel, what is the material around the edge of the panel that stops glass to glass contact. No comment.

You get the picture!

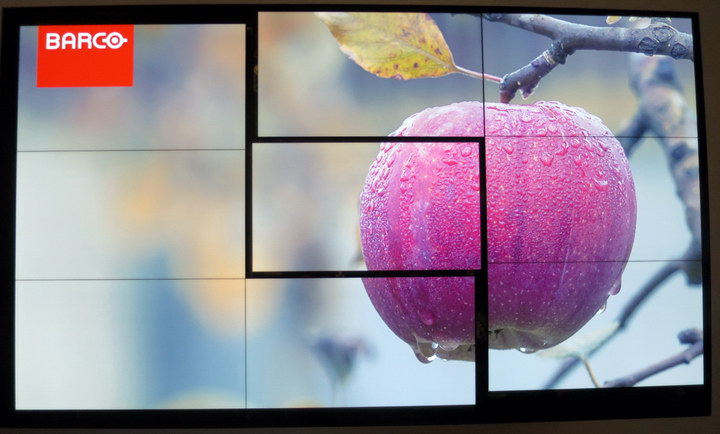

Barco UniSee array with gaps opened up to allow the central panel to be serviced. (Credit: M. Brennesholtz)

Barco UniSee array with gaps opened up to allow the central panel to be serviced. (Credit: M. Brennesholtz)

We were able to confirm that although the initial market is seen as the control room market, where the application is very clear, as Barco does not have cubes below 70″ any more, and the LCDs can offer a very cost effective solution, Barco still sees a good market for the panels in the prestige video wall market. Applications such as company receptions and high end retail are target markets.

Compared to the depth of traditional cubes, the depth of the LCD will be a very good option for control rooms that have limited space. With an external power supply, the wall can be just 94.9mm thick (3.74″) and only 102.4mm with the internal PSU. If brightness is limited to 350 cd/m² (typical is 800 cd/m²), power consumption is just 100W. (so, by our calculation, that means a power consumption of just 121W/m²).

One of the points that impressed Matt was the very good uniformity and matching between panels (Barco quotes this as 95.3% uniformity over 21 measured points and 98% over 9), Sluys confirmed to us that the panels have a closed loop controller that is integrated into the panel. When a video wall is put together, the panels adjust themselves to match. Replacing a panel in an existing wall will also mean that the new panel is automatically calibrated to match the existing panels.

Analyst Comment

I’m still very impressed with this development. Both the assembly challenges and uniformity problems of the narrowest bezel products have really limited the market penetration of ultra-narrow bezel products. My own guess, and it is just speculation, is that the panel probably comes from AUO, which has been doing a lot of work on digital signage panels and will increasingly in the future need to develop a specialist added value business for its fabs. AUO has also developed Gate on Array technology and very narrow bezel panels. Of course, if any of our readers has more certain information, we’d love to hear it!

I think that some of the concepts used in developing UniSee have come from the LED hanging system that Barco has developed (although Sluys could not confirm this as he has only limited knowledge of Barco’s LED history, so far) and I would assume that some of the uniformity and calibration technology may have come from the medical division which is used to closed loop calibration systems. (BR)