3DIcon is a technology company that is focused on their CSpace display technology. Recently, the company published a report in the Journal of Display Technology that describes a new liquid medium in which a volumetric image can be created. This could make the development of such displays much likely to be commercially viable. The article can be downloaded from the March issue (Volume 11, Issue 3).

The paper is co-authored by 3DIcon CTO Dr. Hakki Refai. About a year and a half ago, I had the pleasure to meet with Dr. Refai at their development lab near Tulsa, Oklahoma. What I saw was a volumetric display in a small volume (1-2 inches on the side).

The image is created inside a rare-earth crystal that is needed for the two-frequency, two-step (TFTS) upconversion process used to create the 3D image. But creating a more practical larger image is problematic. For one, it is difficult and expensive to grow crystals that are much larger than 1 cm³. One might bond a number of smaller cubes together, but artifacts at the boundaries can be a problem. Nevertheless, Refai and team still believe this is a viable and cost effective approach to creating a large imaging volume.

In the recently published paper, Dr. Refai explored an alternative solution: a liquid medium. The idea he came up with was to grind up the rare earth-doped fluoride crystals. These were placed in oil-based solutions (10%, 20%, and 30% by weight) that had slightly different refractive indexes (1.45 to 1.49).

Optical characterization tests were done next to evaluate the samples. This measured the rough level of optical scattering (observing the distortion of letters viewed through the solution) as well as a more precise measurement using an 850nm laser (no absorption at this wavelength).

The mortar and pestle method of grinding the crystals created a wide range in particle sizes from 2 to 28 microns, which increased scattering. The impact of the particle size on scattering and emission will have to be evaluated in follow up experiments.

The result of the index variations showed that an index of 1.468 was optimal and produced the least scattering for one concentration on crystals, while an index of 1.472 was optimal for another concentration, not surprisingly.

Green emission is created in these materials by using two lasers at different wavelengths. It is a two-step upconversion process that requires two simultaneous pumps from 1532 and 850 nm lasers. The two IR lasers intersect the sample at right angles and allow the emission of light at the intersection of these beams. A telescope lens sends the emission to a sensor to measure the intensity.

This is quite different from down converting phosphors which use blue light to emit as shorter wavelength red or green light.

Experimentally, Dr. Refai found that the strongest emission occurred at indecies of 1.468 and 1.47, which coincides very well with the optimum for the least scattering. The final result for 10% by weight materials was that two solutions: 1% Er:NaYF4 in 1.468 index solution and 0.5% Er:Ky3F10 in 1.49 index solution, showed the highest emission.

Dr. Rafai also looked at the impact of increasing the amount of rear earth-doped crystals by weight in the solutions. Increasing the percentage from 10% to 20% and 30% decreases the transmissivity and clarity of the samples significantly. On the other hand, the emission strength increased with more material. The right combination depends on the final display size as smaller devices can live with less transmission and use the extra brightness, whereas larger displays, where the distance traveled is longer, can’t sacrifice clarity.

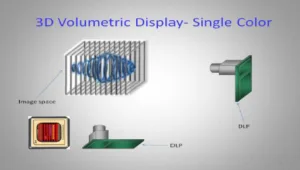

The Cspace display is constructed with two DLP engines oriented perpendicular to each other. The lower engine projects a line of infrared light into the 3D volume to create a plane. The second DLP engine projects an infrared image onto this plane. The 3D volume is created by imaging onto over 1000 slices, moving from front to back, with a refresh rate of 30 fps.

After evaluating the samples described above Dr. Refai created a sample to place into the prototype Cspace display. This is shown in the images below. The displayed gear shows teeth details that are not quite as good as the rendered version, but not too bad.

Going forward, it seems clear that further experiments with the particle size are needed to try to minimize the trade-offs between emission and transparency.

![]()