Display Components, Materials and Manufacturing – Fused fiber optics have the ability to transfer an image from one surface to another with great clarity. This capability has found use in numerous markets including the gaming machine and video terminal businesses (think Casinos). Now, with the expiration of an exclusive licensing agreement and the advent of less expensive polymer fused fiber optics, many new companies in the gaming market are eager to adopt the technology.

On a recent visit with fused fiber optic maker Incom (Charlton, MA), I had a chance to chat with Scott Farland, director of business development at the company. In addition, I was given a tour of its glass fused fiber optic manufacturing line. It is a far more complex process than I imagined to make fused fiber optics, which is why glass-based solutions can be expensive. But Incom also has polymer-based fused fiber optic technology as well, which will be about half the cost to produce.

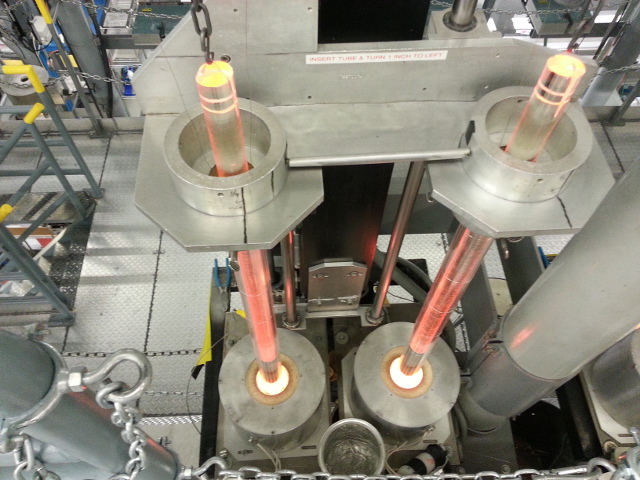

The idea is to take glass or polymer raw material and draw this into 2-4mm diameter fiber optic strands in high temperature furnaces. These strands are bundled together and drawn together tighter and tighter in a very ordered array of high density. The drawing process not only continues to shrink the size of the individual fibers, but it fuses the cladding that surrounds each fiber to create a solid bundle of fibers. Eventually, a bundle of fused fibers (up to 14”x 14”) is created with individual fibers that are on the order of 6 microns in diameter. Such small sized fibers are needed to transfer light from one end to the other with high resolution.

Incom’s fiber optic drawing furnances

Incom’s fiber optic drawing furnances

So, imagine if you placed an LCD panel at one end of the fused fiber optic. At the other end, you will see the LCD image, but now appearing as if it were at the top of the optical bundle instead of at the bottom. Incom can produce fused fiber optics where the cladding on each fiber is transparent or black. The black cladding can increase the contrast of the transmitted image, but it also reduces the viewing angle.

Incom’s fused fiber optic image transfers the image from the business card to the top of the optic

Incom’s fused fiber optic image transfers the image from the business card to the top of the optic

Why is this feature interesting? Because many applications place layers of glass and substrates above the display surface. That means when you look at and interact with the device, the display surface can appear quite recessed. Many find this objectionable – especially if you are interacting with a touch screen display. The distance separation can cause positioning errors with your finger, which can be quite annoying.

In the casino market, there has been an exclusive license for the last five years with Aristocrat Leisure Limited (North Ryde, Australia), a major manufacturer of gaming machines. On Aristocrat’s machines, the company has used a glass fused fiber optic on a number of its “buttons” to bring the image from an underlying display up to the surface. The button was developed by another Australian company, Fairlight, using the Incom fused fiber optic. Fairlight calls this its Picture Key Technology.

I asked Farland what he thought the value proposition was for Aristocrat. “It is really about the aesthetics of the button and the tactile feel. Players like to punch these buttons and having a standard LCD screen with a touch panel does not provide either a differentiated aesthetic, or nice tactile interaction”, explained Farland. “Plus, Aristocrat can simply change the image presented on the buttons to change the type of game being played”.

Incom at Global Gaming Expo.

Incom at Global Gaming Expo.

The construction of the button is fairly simple. An LCD is fitted with the fused fiber optic and surrounded by a hard plastic cover. This displaces when depressed to actuate a sensor. The button can be any shape or contour imaginable.

Farland explained that the company just returned from the Global Gaming Expo in Las Vegas where it exhibited with Fairlight. “We showcased our glass and polymer-based products and the Fairlight button and nearly every game maker came by to see what we had. With the expiration of the exclusive license and the availability of the less expensive polymer fused optic, we were overwhelmed with interest”, exuded Farland.

At the event, Incom showed a 32” monitor that has been masked with different forms of fiber optic parts through the mask and directly mounted to the monitor to showcase its ability to transfer the image about an inch.

Fairlight is actually an AV production technology company with a specialty in AV sound gear. The company will now be taking a more active role in marketing the Picture Key technology to other equipment makers in the AV and broadcast arenas. That could make for some really interesting and useful control surface equipment where buttons can be easily programmed and show the name of the feature they are controlling.

I am sure there are lots of other applications for this enabling technology. Do you have one? – Chris Chinnock

Incom, Scott Farland, 508-765-9151, [email protected]