Back a couple of decades ago (1997 to be precise), I got quite excited that a new display technology had been invented in the UK and the main enquiry office of the developer, the Defence Research Establishment, was in Farnborough, close enough to my home that I used to cycle past. It was called ZBD.

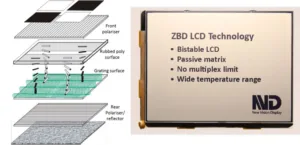

Now, it wasn’t developed in Farnborough, it was developed at a research lab near Malvern in the UK. I first saw it for myself at Display Week in 1998 and was impressed. The technology’s full name was the Zenithal Bistable Display and it was interesting because although it was an LCD, it was truly bistable – once the LC crystals had been ‘nudged’ into a particular configuration, they would stay there without power being applied There’s a good explanation of the way that it works here. E Ink has the same property, but E Ink also needs an active matrix, whereas ZBD uses passive matrix addressing can be multiplexed over many lines because of the ‘memory’ effect.

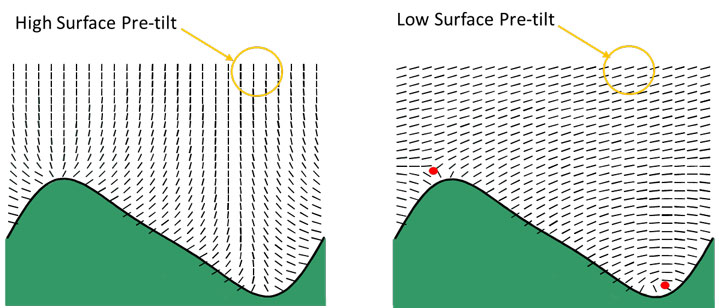

The LC material can be in one of two stable states and can be electrically switched between them.

The LC material can be in one of two stable states and can be electrically switched between them.

In 2000, the technology was spun off into ZBD Technology ande the firm continued to commercialise its technology, which got to mass production with Varitronix by around 2005 with an initial application market in Electronic Shelf Labels (ESLs) a potential market TAM of ‘three trillion’ units. Over the next few years, the firm developed the market and its technology and in 2011 it got additional investment. In 2014, the firm rebranded itself as Displaydata to reflect that it had become more of a supplier of complete labelling systems than just a display technology company.

However, the ESL market was increasingly moving to EPD displays like E Ink because of the ‘paper-like’ look, so in 2019, the ZBD technology was acquired by New Vision Display, a developer of custom LCDs that is headquartered in Shenzen but has facilities around the world. I reported on New Vision when it announced an interesting reflective LCD earlier this year (Reflections on the Desktop – and Outside).

At Display Week, I caught up with New Vision Display US CTO Matthias Pfeiffer and Guy Bryan-Brown based still in Malvern and leading the technical team there. New Vision is an ideal home for the technology as New Vision has its own LCD factories in China and, they told me, there are still incentives to invest in this kind of technology there. The technology can be built with a ‘dog leg’ on an STN production line.

At Display Week, I caught up with New Vision Display US CTO Matthias Pfeiffer and Guy Bryan-Brown based still in Malvern and leading the technical team there. New Vision is an ideal home for the technology as New Vision has its own LCD factories in China and, they told me, there are still incentives to invest in this kind of technology there. The technology can be built with a ‘dog leg’ on an STN production line.

The ZBD technology is basically simple, but there are some critical processes such as the alignment layer as the LC anchoring needs to be consistent. At the moment, the firm can make bistable reflective LCDs up to 16″ with up to 200ppi and because tooling costs are low, it is able to make custom displays with surprisingly low volume because the NRE charges are likely to be very economical.

There are a number of applications gaining attention including handheld devices and even high end CE devices. It can be used in digital signage and an intriguing application is in Industrial switches. These can include LCDs that maintain their state even after power failures – a key feature for this kind of use.

As I mentioned in the article on the earlier reflective LCD, New Vision is very interested in electronic licence plates and in the past we have reported that the ZBD technology is particularly robust mechanically, which is not true of all of the bistable LCD technologies. Obviously, where there is a lot of vibration this can be really important and the technology needs to work in a wide range of temperatures. The ZBD technology can be switched down to -10 deg C and up to 90 deg C and can maintain the image down to -40 deg C and up to over 100 deg C. The

Electronic asset tags are also a good application and one that really amazed me was ‘premium prayer mats’. It turns out that those that need to be able to orient their prayer mats precisely like to have electronics to help with that and they can also be used for recording and training of prayers.

Other applications include voting machines with displays that have the advantage that the data cannot be changed even if there is no power.

New Vision is a processor of Schott and Corning glass, so can arrange cover glass and front lighting and other optical treatments. (BR)