Display Components – A paper revealing a new blue PHOLED technology that could lead to longer battery life in smartphones and other mobile devices has been published in Nature Materials by researchers at the University of Michigan in Ann Arbor. Their developments have extended the lifetime of blue organic light emitting diodes by a factor of 10. They say the technology could also be used in OLED TVs to reduce the power consumption.

Blue OLEDs are the weak-link, compared to red and green OLEDs, in OLED displays such as smartphone screens and high-end TVs. The improvement announced by U of M means not only longer life but higher efficiencies of blue OLEDs, jumping from about 5% to 20% or better in the near future.

Not all OLEDs are created equal. Phosphorescent OLEDs, also known as PHOLEDs, produce light through a mechanism that is four times more efficient than fluorescent OLEDs. Green and red PHOLEDs are already used in these new TVs—as well as in Samsung and LG smartphones—but the blues are the lower-efficiency fluorescent OLED technology.

“Having a blue phosphorescent pixel is an important challenge, but they haven’t lived long enough,” said Stephen Forrest, the Paul G. Goebel Professor of Engineering at the U of M and leader of the team that developed the new technology. He and his colleagues demonstrated the first PHOLED in 1998 and the first blue PHOLED in 2001.

Forrest, the Paul G. Goebel Professor of Engineering at the U of M and leader of the team that developed the new technology. He and his colleagues demonstrated the first PHOLED in 1998 and the first blue PHOLED in 2001.

Now, with their new results, Forrest and his team hope that is about to change. Efficient blues will make a significant dent in power consumption for large-screen TVs and extend battery life in smartphones. The lifetime improvement will also help prevent blue from dimming relative to red and green and allow a more stable white point of the display over time.

“In a display, it would be very noticeable to your eye,” Forrest said, commenting on this white point shift.

Caption: Jaesang Lee, Electrical Engineering PhD Student and co-author of the paper in Nature Communications, demonstrates use of blue PHOLEDs in the EECS Building on August 13, 2014.

In collaboration with researchers at Universal Display Corp. (Ewing, NJ) in 2008, Forrest’s group proposed an explanation for why blue PHOLEDs’ lives were short. The team showed that the high energies required to produce blue light are more damaging when the brightness is increased to levels needed for displays or lighting. This is because a concentration of energy on one molecule can combine with that on a neighbor, and the total energy is enough to break up one of the molecules. It’s less of a problem in green- and red-emitting PHOLEDs because it takes lower energies to make these colors of light.

“That early work showed why the blue PHOLED lifetime is short, but it didn’t provide a viable strategy for increasing the lifetime,” said Yifan Zhang, a recent graduate from Forrest’s group who is first author on the new study. “We tried to use this understanding to design a new type of blue PHOLED.”

The solution, demonstrated by Zhang and Jae Sang Lee, a current doctoral student in Forrest’s group, the Optoelectronic Components and Materials Group, spreads out the light-producing energy so that molecules aren’t as likely to experience the bad synergy that destroys them.

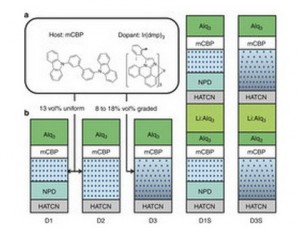

The blue PHOLED consisted of a thin film of light-emitting material sandwiched between two conductive layers—one for electrons and one for holes, the positively charged spaces that represent the absence of an electron. Light is produced when electrons and holes meet on the light-emitting molecules.

If the light-emitting molecules are evenly distributed, the energetic electron-hole pairs tend to accumulate near the layer that conducts electrons, causing damaging energy transfers. Instead, the team arranged the molecules so that they were concentrated near the hole-conducting layer and sparser toward the electron conductor. This drew electrons further into the material, spreading out the energy.

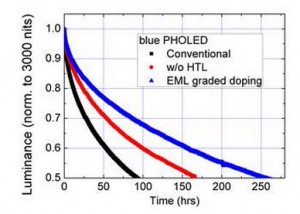

The new distribution alone extended the lifetime of the blue PHOLED by three times. Then, the team split their design into two layers, halving the concentration of light-emitting molecules in each layer. This configuration increased the lifetime tenfold.

“Our university research programs are a strong element of our effort towards solving critical OLED issues and accelerating the growth of the display and lighting industries,” said Julie Brown, senior vice president and chief technical officer of Universal Display. “This exciting result by Professor Forrest and his team is an important step towards a full commercial phosphorescent RGB solution.”

This research is described in a study titled “Ten-Fold Increase in the Lifetime of Blue Phosphorescent Organic Light Emitting Diodes,” appearing in Nature Communications. The work was supported and is licensed for commercialization by Universal Display. –Matthew Brennesholtz

Caption: Figure 1 of the paper in Nature Communications shows a) structure of the host and dopant in the blue PHOLED and b) Structures of the PHOLED device

Display Central Comment

This is a big deal, commercially, although the true impact will depend on some additional issues, that are not yet clear. One of the critical problems for OLED has been that the colours decline at dramatically different rates. The speed of decline in blue was a major issue that meant that displays could rapidly change their white balance – as was demonstrated when Sony launched its first OLED TV, which had problems within 1,000 hours of starting up. To counter this, OLED makers have had to develop compensation schemes that cause serious complications in the design of the driving circuits. If the new technique reduces the need for these compensation, then it will be a big boost for OLED makers.

The second question is on the colour of the blue. One of the problems with blue has been that it has been hard to develop a deep enough blue with the right efficiency, so UDC developed a dual blue scheme. It’s not clear from this news whether this breakthrough helps with this issue, as the blue is at (0.15, 0.29) , well away from Rec 709 at (0.15, 0.06) and further from Rec. 2020. On the face of it, it’s not obvious why it would.

Finally, it’s not clear that there are no issues in manufacturing or in thermal or other areas. However, let’s not be too negative, this looks like a big breakthrough. (BR)