At the SID Display Week 2023 in Los Angeles, there were, as you can imagine, a lot of news stories of OLED technology improvements. Some are more incremental, but one is promising a big jump in performance, lifetime or both.

It reminded me of the time when LCD was dramatically scaling up with prices falling and performance rising. That made life very tough for competing technologies, who often had a roadmap of how to get to where LCD was, but LCD was a rapidly moving target. As hockey player, Wayne Gretzky famously said ‘I skate to where the puck is going, not where it has been’.

This is going to be an issue for technologies, such as MicroLED, if they are going to displace OLEDs which look as though they are on course for a big acceleration in performance. Already, I haven’t heard anybody talk about MicroLED replacing smartphones as OLED is so good and so well established already.

Incremental Changes

I’ll start with the incremental improvements, as there is way less technical risk for those. They are very likely to happen. The bigger change may also happen, but there is a bit more risk that somewhere during development there may be an insurmountable challenge. It wouldn’t be the first time that an OLED roadmap had hit a dead end!

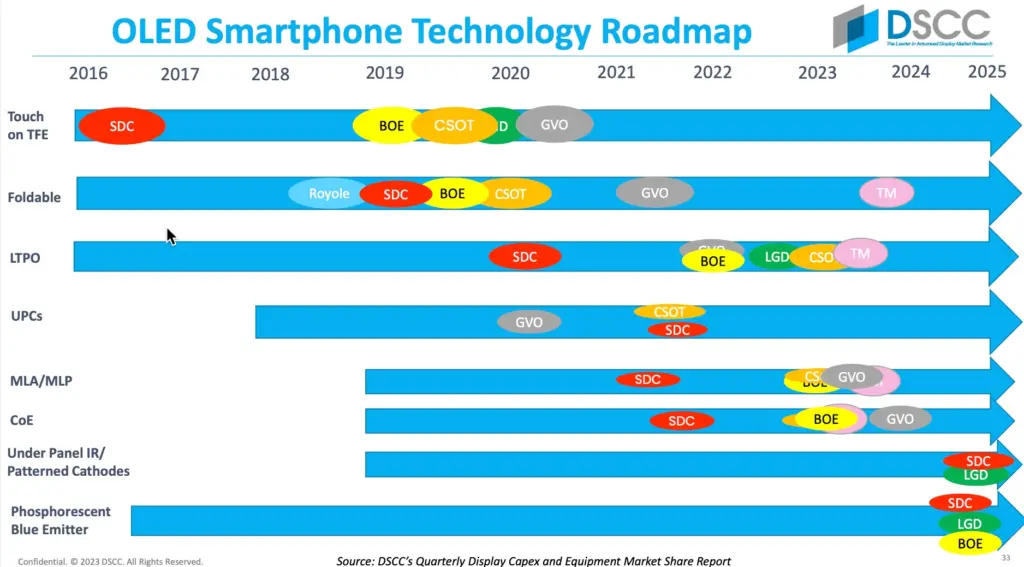

DSCC went through the boosts to OLED at the Business Conference and their comments were reinforced by UDC which is the leading supplier of OLED materials.

Some existing technical developments such as the elimination of polarizers will continue to propagate through the industry’s supply chain. That change in technology boosts light output. The next big change will be in tandem stacks.

Although tandem OLEDs are already in the market with LG Display’s automotive panel, and, arguably, in Samsung’s QD-OLED panel, they are going to get more widespread. They bring a big boost in luminance with an extra OLED layer and are said to be part of Apple’s requirements for OLEDs in panels for iPads and in other IT applications. That’s an application area that will see a big boost in OLED penetration in the next few years (although Ross Young of DSCC kept pointing out in his multiple keynotes, that there is already more than enough capacity for IT panels in the supply chain).

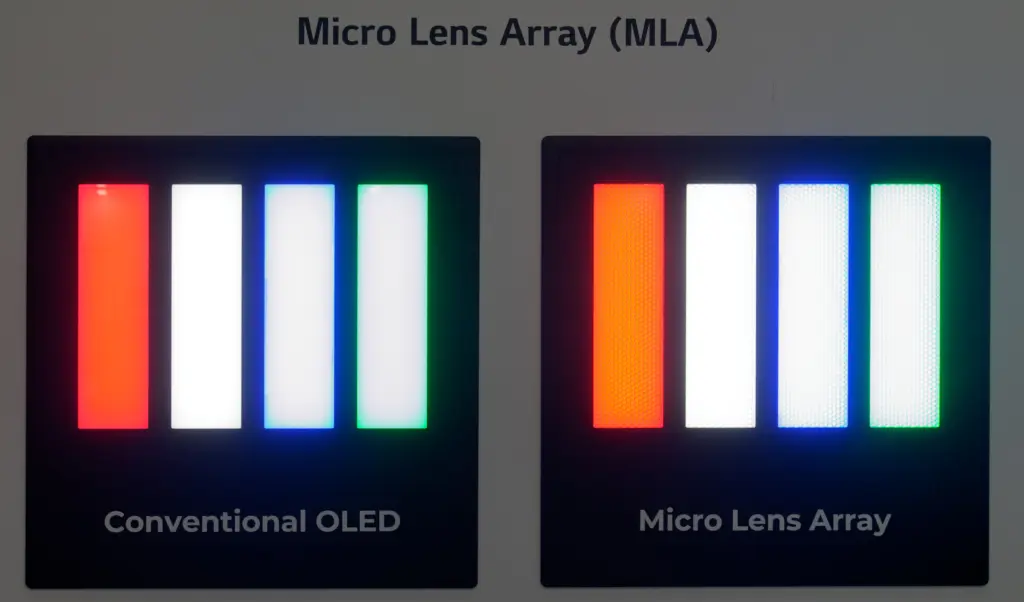

LG Display (LGD) has previously highlighted the use of deuterium to boost lifetime and performance of OLEDs and that technology will be adopted by other OLED brands including Samsung. The same can be said for the microlens arrays that can improve the extraction of the light from the OLED (and is being branded by LGD as ‘Meta’).

Phosphorescent blue is the next development, probably. I say probably because this was due to arrive, according to earlier comments from UDC at the end of this year, with adoption in the market by 2024. However, at Display Week, Mike Hack of UDC was saying materials at the end of 2024 for volume applications in 2025. The slip is disappointing, but we’ve been waiting decades for this development, so I guess we can be patient. The new blue should boost OLED output by 20% to 25%.

(Hack said at that level, but we contacted him to clarify that this is just for RGB displays. Where all (or nearly all) the light is coming from blue – as is the case with Samsung’s QD-OLED, the boost should be a lot more).

It has often been my observation, after a trade show, that the most interesting things are those that are not there. In the case of OLED materials, Kyulux, which has been a developer of higher performance OLED materials did not seem to have a presence on the show floor and although they were listed as speakers for the virtual conference, they were not presenting at the ‘live’ event. Of course, they may have been in a hotel suite somewhere.

Auxiliary electrodes should boost efficiency by 20% or so and the use of low refresh LTPO will also reduce the power consumption, DSCC highlighted.

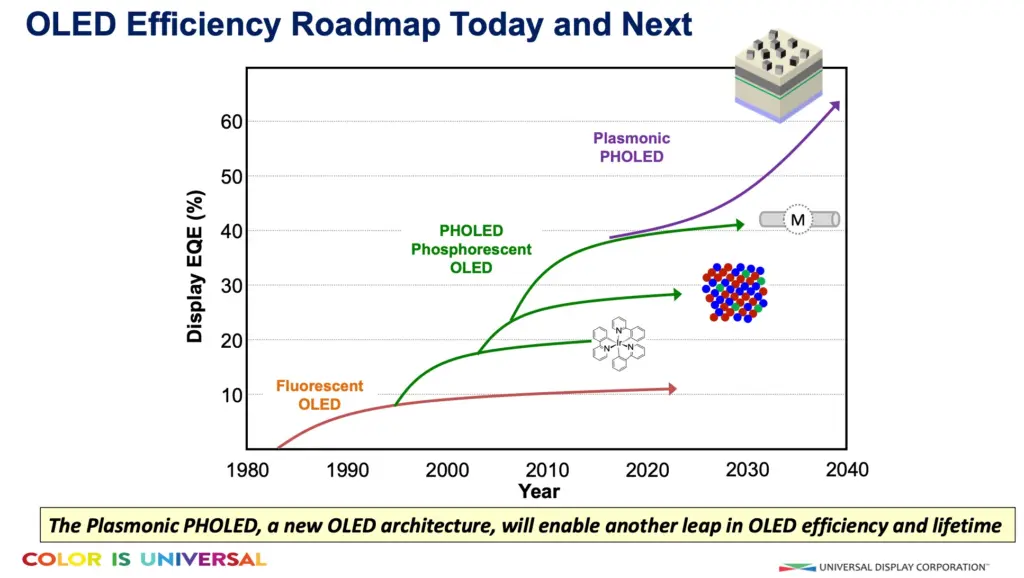

Plasmonic OLED modes are the next big thing, according to both UDC and DSCC. These should reduce power consumption by around 50% (DSCC) and could lead to a 4X increase in lifetime (UDC). UDC said that the EQE could get over 60% and more.

Hack also said that new microIC driving technologies could boost efficiency and reduce power consumption by even more – up to 30%.

Photolithographic Patterning

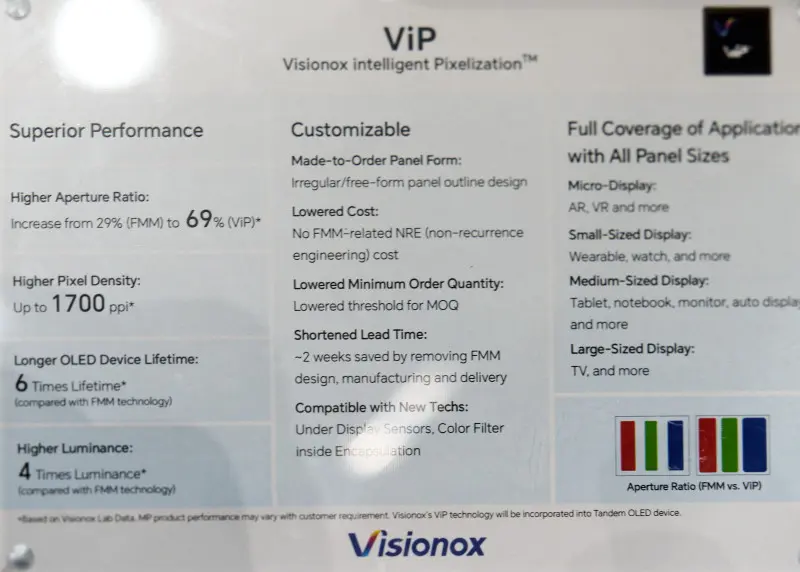

The most dramatic claims for a boost in improvement at Display Week went to Chinese OLED specialist, Visionox. The company was showing smartphone-sized displays made using photolithography to deposit the RGB pixels. It calls its technology and it’s similar to the eLEAP that has been reported from JDI for a year now.

For small and medium-sized OLEDs, Samsung and its competitors use a system of vapour deposition of the OLED material using a fine metal mask (FMM) system (a highly technical ‘stencil’). That means a lot of the OLED material gets wasted. Samsung makes both its smartphone and IT OLED panels using this method. However, the technology has always resisted scaling to the kind of substrate sizes that can support TV-sized panels, although it has been unsuccessfully tried. To get around this, LG Display and Samsung with its QD-OLED have used unpatterned OLED layers with RGB being created by filtering (LG) or QD colour conversion (Samsung). Neither of these is ideal in terms of cost or efficiency.

A second challenge of the FMM process is that the pixels cannot be too close together, so, for a given pitch, the size of pixels is relatively small. The use of photolithography allows the gaps between colours to be much smaller, so the amount of OLED material can increase. The system should also be more economical than vapour deposition as there is less waste in the process. In the past, one of the barriers to the technology was that you need to use quite aggressive chemicals when etching after masking. The processes for the second and third colours would typically damage any material that had already been deposited. One way around this would be use thin film encapsulation to encapsulate each colour after it is deposited, protecting it from later processes. (DSCC presented a speculative process that could do this at the Business Conference)

The net result of the bigger pixels is a big boost in the light output but at the same time allowing a big boost in lifetime as the current density can be reduced. At Display Week, Visionox said that it could get to 1,700 psi with this technique, and with 6X lifetime or 4X the brightness of today’s panels. The firm said that although its current facilities are optimised for smaller panels, the technique could be used for IT or TV-sized panels.

When you look at the speed on the ice of the “OLED puck’, there should be shiver going up the spine of every competing technology which is now going to have to aim even further ahead!

Bob Raikes is semi-retired from the display industry, but still edits the 8K Association newsletter and contributes to Display Daily.