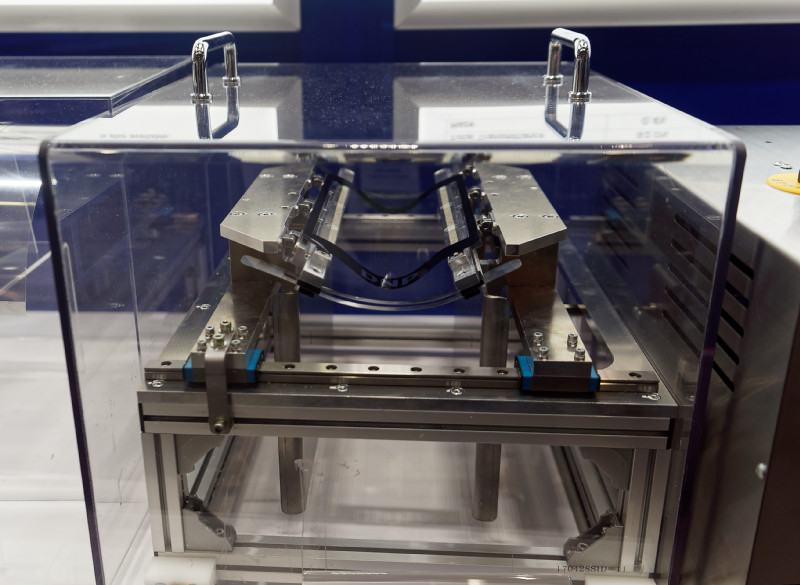

DNP of Japan was showing a new Louvre Array Film that is designed for automotive applications and that can block reflections on the windscreen of autos from displays in the car. The film can also be used to create fixed privacy films. The company also showed a new flexible hard coat film for OLEDs and LCDs. The film is under development but has been tested with 1 million bends and can also resist damage. There are two versions, one with 5H hardness and one with 8H hardness, The transmittance is 92% and haze is 0.4%. The company showed the machine that had been used for testing the flexibility.

DNP uses this flex test to test its protection films for flexible displays. Image:Meko

DNP uses this flex test to test its protection films for flexible displays. Image:Meko

DNP is also working on flexible colour filters, depositing the filter on a PI substrate on a carrier glass. The company is working on including a touch sensor in the filter and claims advantages as it can put the wiring under the black mask of the filter. The company can also deposit fixed patterns such as borders around the edge of the display.

Eldim, which is better known for metrology, was highlighting that it has other display knowledge. The company has developed, at the request of Prismaflex, a supplier of LED displays in France, a new driving method for LEDs that was being shown at the exhibition. A paper was also presented at the symposium. Traditional discrete LED displays use multiplex driving and this can cause problems with colour break-up especially when the display is photographed or video recorded. Of course, this is a particular advantage where big LED displays are installed in TV studios – a popular application for the technology. The system also improves power efficiency and device lifetime.

Eldim has a new driving method that reduces the problems of video recording LEDs. Image:Meko

Eldim has a new driving method that reduces the problems of video recording LEDs. Image:Meko

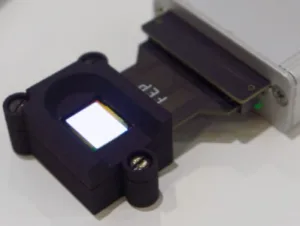

The Fraunhofer FEP was on the German industry booth – a big one – and we looked at two developments. The first was the bidirectional display/camera that the company has developed that was being shown in a fingerprint recognition system. The technology allows very high resolution imaging compared with other approaches and cannot be fooled with ‘fake fingers’ and can even identify millipores in the skin. The size of the chip means that the sensor cannot be a low cost solution, but it can be very high security and is unlikely to make it into mainstream applications such as smartphones.

Fraunhofer showed this fingerprint sensor – the image of the print is on the left. Click for higher resolution. Image:Meko

Fraunhofer showed this fingerprint sensor – the image of the print is on the left. Click for higher resolution. Image:Meko

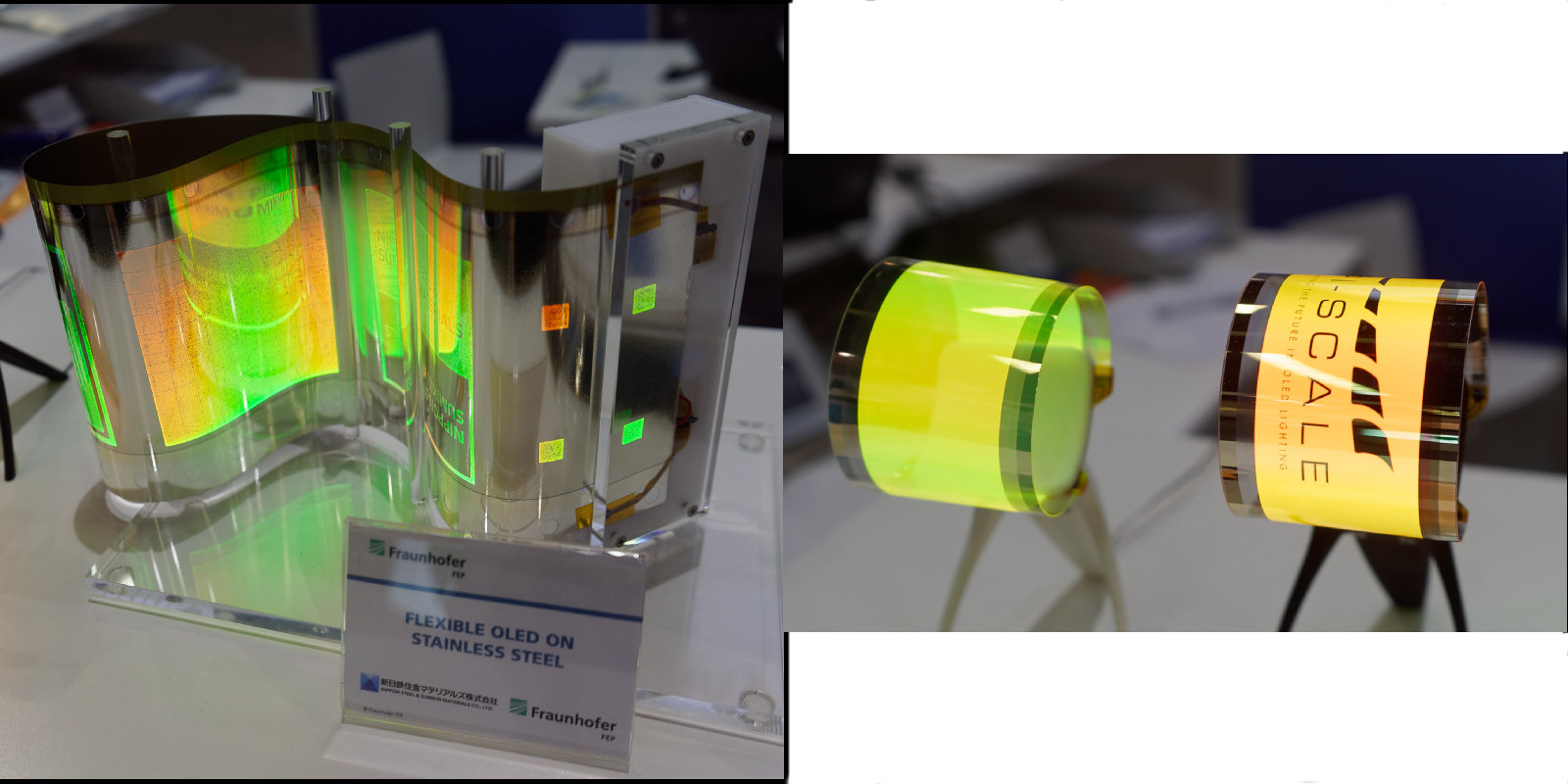

The Fraunhofer was also showing the use of stainless steel as a substrate for flexible OLEDs. The foils were very thin – on show were substrates of 30 microns thick, but they could be at any thickness from 8 micron to 30 micron. The group is also testing cheaper carbon steels and the material can be process using an R2R process and in a variety of widths. In a top emission structure OLED, there is no need for the substrate to be transparent, and stainless might make a lot of sense because of the strength. The Fraunhofer is also able to develop titanium solutions. Also on display were transparent plastic film substrates.

Fraunhofer showed flexible OLED substrates – stainless steel on left, plastic on right. Images:Meko

Fraunhofer showed flexible OLED substrates – stainless steel on left, plastic on right. Images:Meko

The Fraunhofer was also showing the latest version of its NTE display that we last reported from Electronica and that has now been fitted with bluetooth for data update.

Fraunhofer has added bluetooth to its NTE display system. Click for higher resolution. Image:Meko

Fraunhofer has added bluetooth to its NTE display system. Click for higher resolution. Image:Meko

LG Display had an impressive display at SID, but didn’t have anything new compared to the suite-based demonstration at CES in January. The 77″ Wallpaper OLED was impressing everyone. It really is amazing when you think how far we have come in the last twenty years!

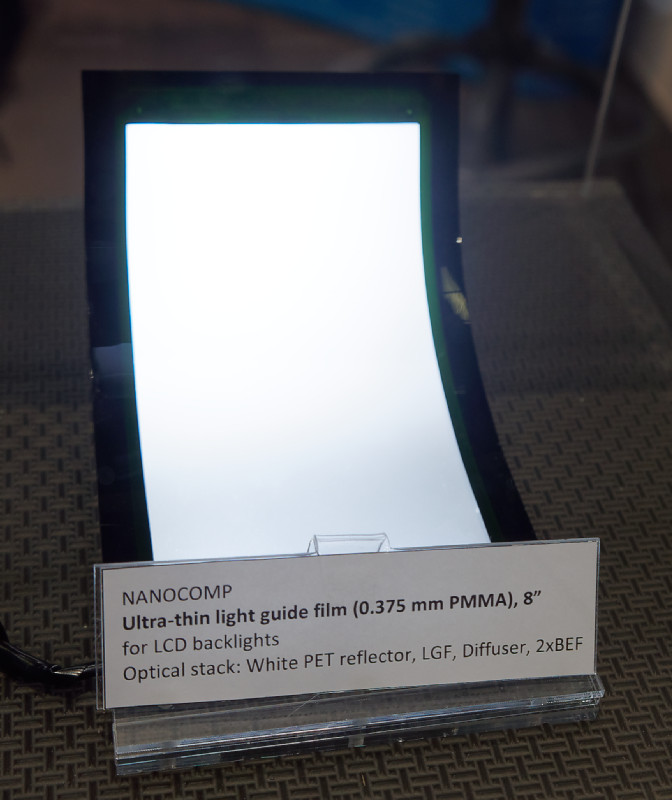

We mentioned Nanocomp in a short article before SID (Nanocomp Claims Thinnest Light Guide) and met with them on the show floor at the SID where the company was showing its flexible and ultra-thin light guides. The guides are made using a R2R process and the micro pattern is created using U/V light on a special lacquer. The patterns can be designed for backlighting or front lighting and the company was showing an 8″ guide that was just 0.375mm thick. The company has full facilities for design, manufacturing and tooling and is vertically integrated into the materials and chemicals as well. One application where the flexibility of its light guide plates comes in particularly useful is for wrist-worn displays. The company told us that the acrylic films that it typically makes its patterns on are quite strong and robust.

Nanocomp’s light Guide is thin and flexible. Image:Meko

Nanocomp’s light Guide is thin and flexible. Image:Meko

Glass company, Pilkington, a member of the NSG group, was showing its MirroView product designed for touch mirror displays. New this year is OptAR Plus, a glass with an anti-reflective (A/R) coating. It offers an alternative to the firm’s OptiView glass. NSG Glanova is a chemically-strengthened cover glass with an A/R coating and was being shown in a glass/polymer combination. The company also is working with Tactus to use the Tactus TrueWrite film with Glanova to deliver cover glass that works well with a stylus as well as reducing breakage and providing a self-healing surface.

As well as its stretchable display, Samsung Display was showing a 2250 ppi LCD panel for AR/VR applications. The transmissive panel which is based on a glass substrate using LTPS, rather than crystal silicon, has 3840 x 2160 resolution on a 1.96″ diagonal. The pixels have a triangle structure and short channel TFTs.