On the Monday of Display Week, I sat down on a flight of stairs at the Los Angeles Convention Center for an interview with Janice DuFour (formerly Janice Mahon), VP of Tech Commercialization and GM of the PHOLED Material Sales Business for Universal Display Corporation. UDC is a Wall Street darling at the moment, with its share price having risen from about US $50 last November to roughly US $117 at the time of this interview. The May 2017 rise of 27% was attributed to strong Q1 earnings. The company’s 2016 acquisition of the privately owned contract research organization (CRO) Adesis was also regarded favorably.

On the Monday of Display Week, I sat down on a flight of stairs at the Los Angeles Convention Center for an interview with Janice DuFour (formerly Janice Mahon), VP of Tech Commercialization and GM of the PHOLED Material Sales Business for Universal Display Corporation. UDC is a Wall Street darling at the moment, with its share price having risen from about US $50 last November to roughly US $117 at the time of this interview. The May 2017 rise of 27% was attributed to strong Q1 earnings. The company’s 2016 acquisition of the privately owned contract research organization (CRO) Adesis was also regarded favorably.

UDC predicts even greater growth in the OLED displays market, and has said that its next generation of emitters are now being adopted by customers. But with doubts increasing that OLED really will displace advanced LCD as the television display of choice, and with increasing speculation about TADF as an eventual competitor to UDC’s phosphorescent OLED (PHOLED), are the growth projections overly optimistic? We embarked upon this interview hoping Dufour could enlighten us. (Note: Dufour’s answers are paraphrased, except when included in quotes.)

KW: You’ve announced that a new generation of PHOLED emitters are now being adopted by your customers. What are these emitters?

JD: We introduced a new set of materials in 2016, and new emitters are currently in design cycles with some customers. There are improvements in lifetime and efficiency, but the big difference is that we are now designing for customer requirements instead of just releasing a new emitter once in a while. A lot of what we are doing is customizing our materials for a specified output.

In general, customers want high dynamic range and high luminance to compete with QD LCDs, but the emphasis does change. Lifetime can be the high priority one year, and efficiency the next.

KW: Do you see synergy in the acquisition of Adesis, or was this primarily a portfolio expansion?

JD: Adesis has been a CRO (contract research organisation) supplier for us. R&D programs were suggested by Julie (UDC CTO Julia Brown) or by new chemistries. Adesis was such an important part of our research and development that acquisition made sense for us. And Adesis was looking for growth and personal security for owners.

There is a meaningful CRO business for Adesis, both in OLED and in other areas. They provide support for difficult chemistries for pharma, agriculture, synthesis, and other areas. Early-stage mass production is their specialty, and they have space to grow. They will pursue more OLED business in the future.

KW: Is TADF a threat to PHOLED?”

JD: “TADF is an interesting technology but it is not a meaningful threat in the short to medium term. It takes a lot of time to get efficiency, life, and color right all at the same time, and then move into manufacturing. And once a company is tied into a system, it’s hard to move.”

Adesis worked on TADF for quite a while, so the technology is not new to us.

KW: Blue? (Note: Despite years of work, UDC has not yet produced a deep blue PHOLED emitter with appropriate efficiency and lifetime, which is needed for an all-phosphorescent OLED.)

JD: “Internal momentum is building,” thanks is part to the BSF patent portfolio we acquired in 2016. The portfolio enhances our strength in chemical modeling and digial chemistry. The team we have working on blue are expressing “exciting positive momentum”

KW: Is there anything else I should have asked you?

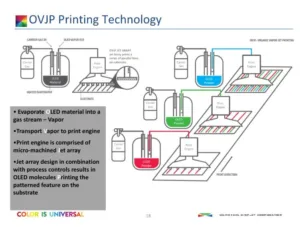

JD: “We are also dong more work on OVJP [organic vapor jet printing] technology. Samsung and LG are happy with what we are doing. OVJP combines VTE [vacuum thermal evaporaton] and IJP (ink-jet printing).” We’re in R&D, but we are also building a pilot-scale tool and looking for a partner. There is potential for large scale TV screens.

Immediately after the interview, UDC VP for Business Development Mike Hack delivered a paper at the SID/DSCC Business Conference entitled “Color is Universal; New Opprtunities for Phosphorescent OLED Displays. In addition to addressing several of the topics covered in the Dufour interview interview, Hack noted that if a cell phone produces 1000 cd/m² peak white luminance, it means that some sub-pixels must emit 5000 or 10,000 cd/m². Hack said that UDC red PHOLEDs maintain over 98% of an initial 3000 cd/m² luminance for 500 hours; green maintain over 98% of 10,000 cd/m² for 500 hours; and yellow maintains over 98% of 3000 cd/m² for 500 hours. He added that matching the emitter and host materials “is key to achieving commercial lifetime performance.”

Hack described OVJP in some detail. Despite a lot of work, he said, developers of solution-based-processed OLEDs have not been able to achieve the performance of VTE-deposited materials. OVJP, he said, combines the advantages of both approaches. Steve Forrest (then at Princeton, now Michigan) invented OVJP around 2005. The method evaporates emitter material (as VTE does) and then jets the vapor onto a substrate in the desired pattern (as IJP does). Recent work at UDC, said Hack, has produced the necessary line width.

Hack also described the blue/yellow hybrid approach that we covered in a Display Daily last year. (UDC Works on Hybrid OLED Approach)

[Disclosure: The author owns (a very modest number of) UDC shares.]