Up to now, OLED makers have been making OLEDs using technologies that are effectively limited by the barrier in fine metal mask patterning that Kodak (and its Sanyo Kodak subsidiary) hit several years ago. LG uses colour filters, which are inefficient and Samsung Display had to pull back from its OLED TV panel manufacture because of the difficulties. But, there might be another way….

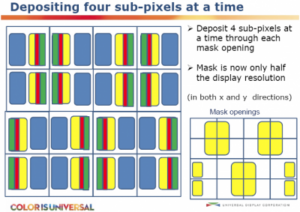

UDC, the developer of OLED materials, has had a think about this issue, with some help from pixel architecture maven (and occasional Display Daily contributor), Candice Brown-Elliot and has an alternative. We caught up with Mike Hack of UDC to understand more about the approach.

Ideally, in making an OLED you’d pattern the different materials for red, green and blue so that you can balance them and that is what Samsung does on its small OLED displays. The best way to deposit the materials is to use a fine metal mask (FMM), but unfortunately this gets too inaccurate at larger sizes. LG has got around this by using a stack of different OLED materials that create white. without patterning, but then putting a filter on top, like an LCD. Not only does the filter cost real money, it also means that much of the light is simply thrown away in the filter (at least two thirds). Given that OLED is challenged in brightness at the moment and lifetime issues (that are made worse by pushing the materials harder), that’s bad news all around.

Ideally, in making an OLED you’d pattern the different materials for red, green and blue so that you can balance them and that is what Samsung does on its small OLED displays. The best way to deposit the materials is to use a fine metal mask (FMM), but unfortunately this gets too inaccurate at larger sizes. LG has got around this by using a stack of different OLED materials that create white. without patterning, but then putting a filter on top, like an LCD. Not only does the filter cost real money, it also means that much of the light is simply thrown away in the filter (at least two thirds). Given that OLED is challenged in brightness at the moment and lifetime issues (that are made worse by pushing the materials harder), that’s bad news all around.

Furthermore, there is a market trend to higher and higher resolutions and that makes things worse and worse.

So UDC has approached this differently. One of the areas that has been weak in OLEDs has been the efficacy and luminance of blue pixels, and driving them hard reduces the lifetime, so it’s good to have a big blue pixel. However, if you substitute yellow for the red and green, you reduce the number of deposits of OLED dots that you have to apply (or you can make higher resolution with the existing pixel density).

Now, another big trend is the move to wide colour gamuts. If you simply have a yellow pixel, then too much light that is somewhere between red and green may be produced and that can reduce the purity of the primaries, which means a smaller gamut. (Laser phosphor projectors also have this problem and have to put in a filter to ‘separate’ the colours). UDC’s concept does this differently, and adds red and green filters over just part of the yellow sub-pixel which allows a wider gamut to be produced, where really saturated colours are needed. On the other hand, when pure colours are not needed, the light can be emitted from the yellow, and little light is lost in filters.

If you stay with the same resolution, you also reduce the space used for buslines and TFTs as you only needed two sub-pixels per pixel. UDC found that this change, alone, boosted the potential aperture ratio of a blue sub-pixel from 8% to 15% and that means a potential increase in lifetime of 3.3X compared to an RGB architecture.

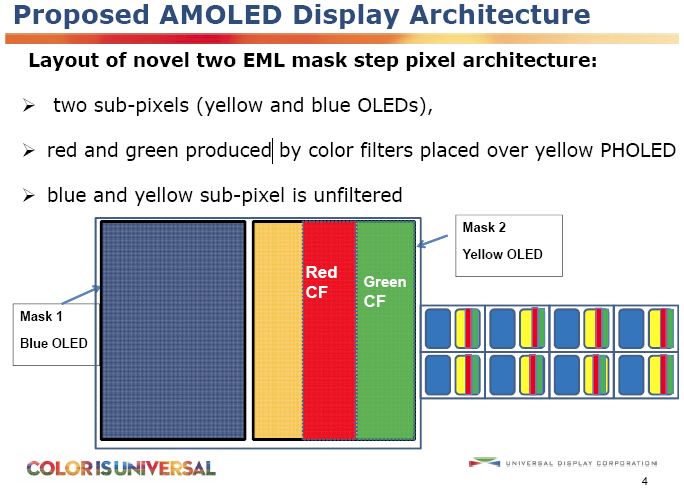

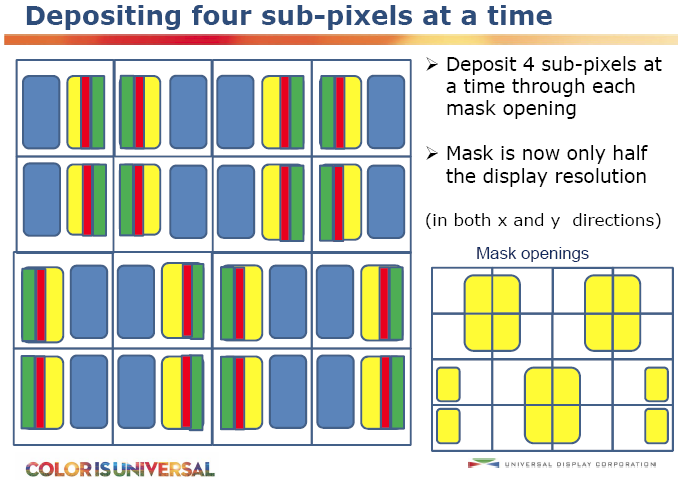

The next step for UDC was to look at other ways of configuring the pixels to make it simpler still. First, if you deposit the colours differently in alternate lines, you can deposit four sub-pixels at a time, minimising the accuracy needed in the mask or potentially opening up other deposition methods. That boosts the blue aperture ratio to 19% and multiplies lifetime by 4.8 times (because you can reduce the current density of the blue).

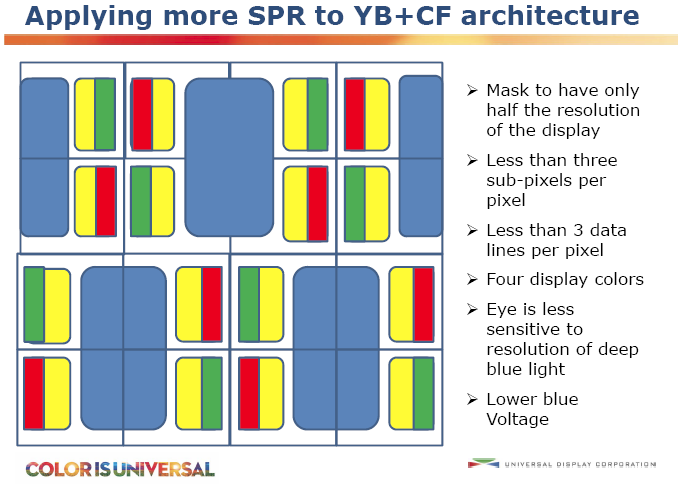

By then exploiting the features of the human visual system, which has its peak resolution in yellow, you can simplify the red and green filters, applying them alternately over the yellow area. You can also print two lines at the same time which simplifies manufacture.

Now, there are those that worry about this kind of sub-pixel addressing and the International Display Measurement Committee is heavily involved in looking at the question of “what is resolution?”. Having seen some test patterns on an LG RGBW ‘UltraHD’ set recently, when I visited Quality TV in Germany, I can understand the concerns. However, if this kind of technique is well implemented and properly managed and adjusted, it should be fine when you have high resolution displays with video-sourced images.

More importantly, this kind of approach might open up the possibility of improving the lifetime, performance and efficiency of OLED TVs, while making them simpler to make and of lower cost. It is, effectively a kind of ‘hybrid’ between the previous Samsung and LG approaches.

Hack told us that UDC has kept working on this topic and plans a further paper, perhaps at IMID or at the OLED World event in September. He also said that UDC has ip in this solution, but is working on the concept to help the supply chain. He has considered getting a sample made, but the driving and backplane would cost a lot of money, while a ‘one-off’ is bound to have defects and that sometimes puts people off. (BR)