A couple of weeks ago, I spotted a quote by Ross Young of DSCC in an interview where he said that “There are a number of near-term advances expected in reducing power ….. These developments combined could reduce OLEDs power by more than 50%”. That struck me as interesting and significant and so I followed up with him to find out more.

Reducing the power consumption of OLEDs is important. When showing video or dark images, OLEDs have advantages over non-miniLED LCDs as only the pixels that light up use power and only to the degree of their brightness. However, in IT applications, reverse contrast, with dark text on a light background is better and LCDs can gain an advantage. OLED is doing really well in smartphones, but still has only low penetration in TV, some in tablets and has little in notebooks. It has, effectively, zero penetration in desktop monitors. Reducing the power consumption of OLED would really help the penetration in notebooks and tablets.

1 A Better Blue

A relatively simple to understand improvement, but one which is extremely difficult to achieve, is to improve the efficiency of blue OLED materials. Since the breakthroughs in developing phosphorescent OLEDs (PHOLEDs) in red and green in the naughties, the efficiency of blues with a colour that is suitable for displays has lagged well behind red and green. Despite huge efforts, and improvements in the blues available, blue still lags well behind the other colours. Most recently on DD, Ken wrote this article on the topic (What’s a Kyulux?).

Now, companies have developed some work-arounds for this by creating tandem device structures that combine relatively high efficiency light blue with some dark blue for when it is really needed, for example in TV panels using WOLED, but this adds cost and complication. The big topic at CES next month will be the Samsung QD-OLED which uses blue as the emitter. It is reported to need three different layers of blue to reach the performance needed. A better blue would make the system more cost effective by reducing the number of layers of material needeed.

2 An Auxiliary Electrode

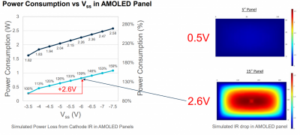

This was a new topic for me, so I got more from Young. He explained that the issue that can be improved is a problem in larger displays that is known as IR drop – that is to say the power lost in the electrode from the current being carried multiplied by the resistance of the electrodes.

For those that don’t know, it is not trivial to get the right voltage (in the case of LCDs) or current (in the case of OLEDs) to the right pixel at exactly the right time to create a great image. Higher resolutions and higher frame rates reduce the time available (so increase the frequency of the driving signal) and large displays mean longer electrodes. The electrodes on the front of the display also have to be invisible, which can be done by making them very very thin or by making them bigger, but more transparent. Typically there is one of those real-world engineering trade-offs. Making a transparent electrode thicker reduces the resistance, reducing the R in the IR calculation, but makes the transparency worse.

The voltage across the display drops because of the resistance of the electrode which for any particular pixel is in proportion to the distance from the edge of the display. That problem can be solved by modulating the voltage (Vss) used to drive the display, but the IR voltage drop problem remains.

Three years ago (and several times since), I reported on new materials for electrodes from OTI Lumionics that can be used to create self-patterning electrodes that help with the development of panels that can have ‘holes in the cathode’. Holes in the cathode are needed for the development of under panel sensors and cameras. At the time, OTI pointed out that cathodes haven’t really changed for thirty years or so.

It turns out that the OTI technology can also be used to help with the IR challenge by adding an additional cathode. The technology puts a very small (10um, <1?/sq) additional patterned metallic cathode connected to the normal sheet cathode. (Imagine an incredibly fine conductive set of lines bonded to a transparent sheet) That gets the current to the area of the pixel at a much lower value of R, improving the efficiency and reducing the voltage drop.

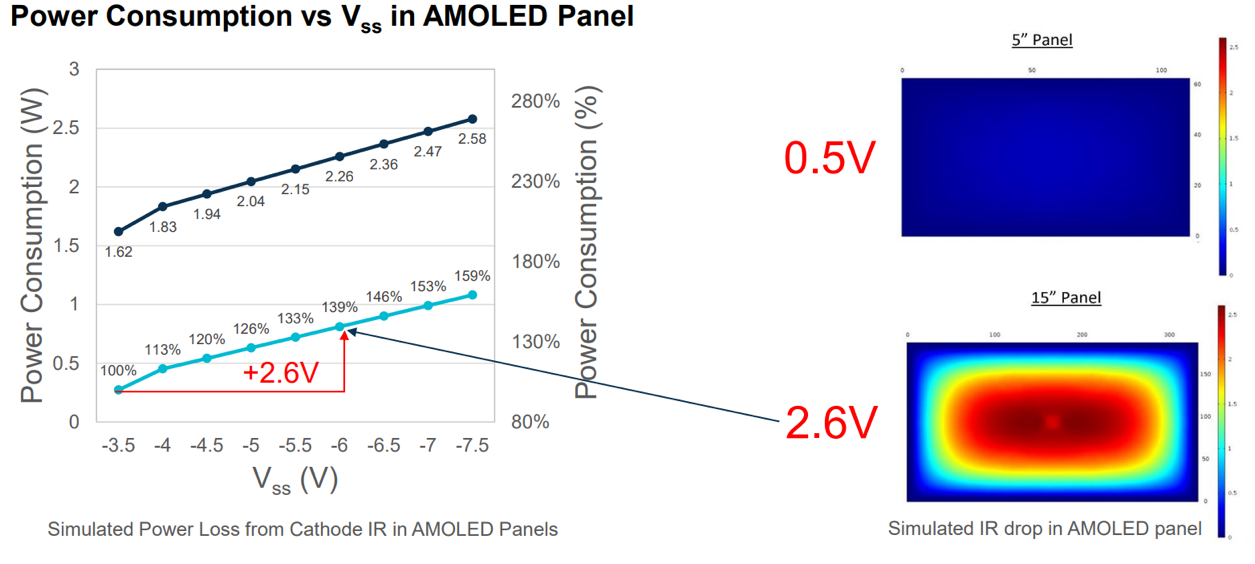

Of course the combined resistance of the two current paths – the traditional cathode and the extra cathode – give an overall lower resistance. The big win from this is an overall improvement in the OLED power efficiency. Up to now, buying a notebook with an OLED has meant a significant drop in battery time, and that has been a big barrier to adoption. (One of my friends at Lenovo, despite his high executive position, always chooses the lowest resolution notebook for this reason alone).

OTI said that the electrode can be put between the pixels, above the pixels or even on the backplane.

Young shared this chart with me which shows that with most levels of brightness, a notebook could have power consumption of almost the same as an IPS LCD.

3. Colour on Encapsulation

Colour on Encapsulation (COE or POL-LESS) technology removes the polariser that typically sits on the front of an OLED to improve contrast and replaces it with a colour filter. That saves power and is being adopted. We have generally discussed this technique with respect to smartphones, but the logic of the concept applies equally to larger OLED displays. Barry covered it in a Display Daily earlier this year (Samsung’s Z Fold 3 Thinning Innovations Could Make All Flexible OLEDs Brighter)

4. Better Transistors

Backplane technologies are getting better and better with the best IGZO starting to rival the lower levels of LTPS, but at a lower cost. That’s a topic I’m planning to make a deeper dive on shortly (and helps LCDs as well as OLEDs).

Summary

So, these three innovations, combined with detailed improvements in the other materials in OLED stacks could add up to a 50% boost in power efficiency. At the moment, it remains a strong probability that Samsung Display will go ahead with a big investment in a new G8.5 fab to make OLEDs for IT and these innovations could well be part of the calculations by Samsung on making OLEDs more competitive for IT applications.

DSCC has, of course, dug into these topics in more detail in its reports. (BR)