In Samsung’s quest to make OLED panels thinner, the company discovered a way to increase the luminance by 20% to 30%.

The typical OLED panel configuration, includes:

- An active matrix using LTPS or IGZO or LTPO (using IGZO for the driving TFT and LTPS for the switching TFT)

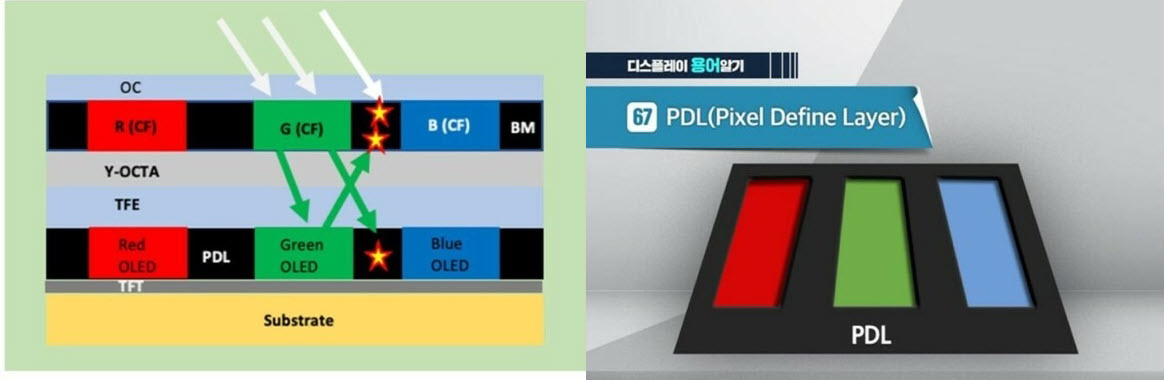

- A yellowish pixel defining layer (PDL) made from polyimide (PI) patterned on the active matrix

- The OLED stack

- A black matrix

- Encapsulation, either glass for rigid displays or TFE (Thin Film Encapsulation) for flexible displays

- A 1/4? polarizing film (circular polarizer)

To get the display to fold properly, Samsung has reduced the overall thickness by replacing glass with PI and then the cover lens with ultra-thin glass (UTG) and combining layers. The circular polarizer serves an important function as it diverts incoming light away from the image but that comes at a cost of 100?m. (although DSCC reckons that 56-88 microns is mor e typical in the market – editor) The circular polarizer works well by distributing the ambient light, but it also blocks ~50% of the light generated by the OLEDs.

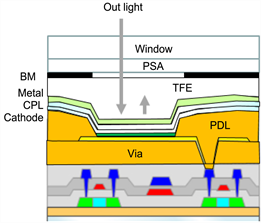

Samsung is working on replacing the partially reflective yellowish PDL with a black light absorbing PDL, eliminating the circular polarizer, and adding a color filter that is placed on top of the red, green and blue OLED sub-pixels. This type of color filter does not block 2/3rds of the light as would a standard color filter as it only affects the light with the wavelengths for the desired color.

The Roadmap

SDC’s roadmap includes eliminating the polarizer with an On Cell Polarizer (OCP) or Color on Encapsulation (CoE). It improves foldability as the additional layers used to replace polarizers are thinner than the polarizer. The polarizer is replaced with a Black Pixel Defined Layer (PDL), a black matrix (BM and a color filter.

The PDL is formed outside the deposition area before the sub-pixels are deposited and effectively minimizes the reflections caused by external light. Sumitomo has been the primary supplier of circular polarizers to Samsung. The use of an OCP should reduce the panel thickness by ~90?m (46?m-78?m), as the circular polarizer is ~100?m (56-88) and the COE is <10 ?m.

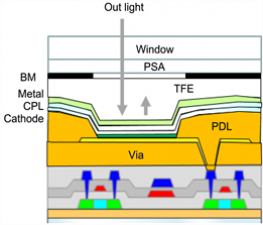

Cross-Sectional View Diagram Of OLED Panel. Source: SDC

Cross-Sectional View Diagram Of OLED Panel. Source: SDC

Since the yellowish brown polyimide layer of PDL reflects the ambient light, the visibility of the OLED display is reduced, especially in high ambient conditions and a circular polarizer is layered on top of the black matrix pattern layer as shown in the cross-sectional view of OLED panel in the next figure.

The 1/4? polarizing film has a ~100?m (or 56-88?m) thickness and also reduces the light output by up to 50%. By patterning the PDL with a black photoresist, the black matrix pattern and 1/4? polarizing film would not be required to constrain the ambient light which reflects off the cathode.

However, the photosensitivity of the positive-tone polyimide is not high enough to give black PDL patterns which have thickness of 1.0 – 1.2 µm. Samsung developed a negative-tone photoresist used for the photolithographic patterning of black PDL of OLED, since the polymerization depth of UV light is deeper than that of positive-tone photosensitive polyimide.

The result is a negative-tone photoresist for the photolithographic patterning of PDL with black color since the penetration depth of UV light is deeper than that of positive-tone photoresist containing photosensitive polyimide. But the black PDL, cannot block all the ambient light and various anti-reflective films were tried, but none were acceptable. The solution required a color filter and black matrix to be patterned on top of the Y-OCTA layers, which adds an estimated five masks to pattern the BM, RGB color filter and OC layers, and requires additional lithographic tools

Since the color filters are color on color as opposed the color on white, the light loss through the CF is small, at <15%, comparable to quantum dots used to convert blue to red and green. According to DSCC’s blog from a week earlier, the current prototypes made using the POL-LESS process have increased brightness by 20% to 30% and combining POL-LESS and LTPO will reduce power consumption by more than 30%. This new approach, which has been called On Cell Polarizer (OCP) or Color on Encapsulation (CoE) should reduce the panel thickness by >90?m.

Figure 7: Samsung Display’s POL-LESS AMOLED Structure and PDL Source: DSCC, ETNews

Figure 7: Samsung Display’s POL-LESS AMOLED Structure and PDL Source: DSCC, ETNews

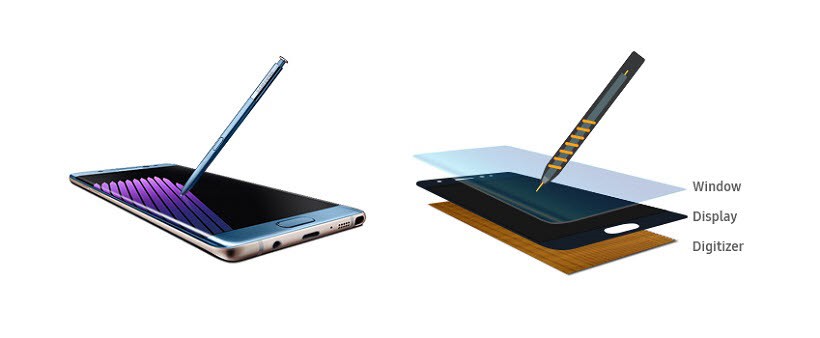

Other expected changes in the Z Fold 3, include:

- Adding the S-Pen, which detects a magnetic field created by the movement of the pen which uses a digitizer to convert the movement into electrical signals. The digitizer is supplied by Interflex. The Pen will be mounted into the foldable display

- Strengthening the cover window to withstand the pressure applied by the Pen. The cover window uses UTG and must be both durable and provide a smooth luxurious feel. Dowoo Insys, a Samsung controlled company, provides the UTG processing to glass supplied by Schott. DSCC points out that the key message on the UTG for the Z Fold 3 is that it will be stronger, likely thicker, which allows it to pass the pen drop test.

- Adding a UPC for selfies. The sensor is being developed by SEC’s LSI group. Samsung reportedly uses a technique that enlarges the pixel pitch under the camera to provide sufficient light to enable photographs, but not large enough for the user to notice the difference.

- Automatic pairing of the stylus to the phone as it recognizes the S Pen when hovering over its screen. It also shows a slew of options when tapping the floating button that appears on-screen. It supports:

- Taking notes and drawing, and in Live Messages drawing personalized emojis, create GIFs, scrawling notes on photos.

- By selecting AR Doodle the S Pen can draw in a 3D space.

- Smart Select, will select, clip, and collect images or videos to quickly share with friends.

The S21’s S Pen can’t do exactly the same things that a Galaxy Note can, but Samsung hopefully will release a fancier and more expensive S Pen Pro in unison with the release of the Z Fold 3. The advanced stylus will work as a remote shutter for the phone’s camera and unlock Air Gestures, similar to what the Galaxy Note’s stylus does.

Smartphone w/Stylus Source: ETNews

Smartphone w/Stylus Source: ETNews

The result is a foldable OLED panel that is up to 90 µm thinner, emits 20% to 30% more light with a tighter folding radius, an UPC and a digitizer. The downsides are 5 extra masks to pattern the color filter and the black PDL with the associated capex and potentially lower yields and ambient light blockage that is not quite as good as the circular polarizer. Due to the extra equipment for the masks, Samsung will reduce the capacity of the fab by10% to 15%. Samsung expects to optimize the process for foldables, which have lower volumes and higher margins and then potentially apply it to standard flexible OLEDs. (BY)

Sources: Samsung, DSCC, ET News Barry Young is the CEO of the OLED Association

[1] The black negative photoresist include photoinitiator, photosensitizer, binder polymer developable with aqueous alkaline solution, multifunctional monomer for crosslinking reaction, black millbase and polyimide to increase the thermal stability of patterned black PDL of OLED devices. The last component of the black negative photoresist is critical, since the process temperature of black PDL reaches close to 300?C including post-curing step after photopatterning, which is why photosensitive polyimide has been used in the normal (not black) pixel define layer patterning. Another requirement is the complete solubility of all the components of negative photoresist in the common organic solvent in this case propyleneglycol monomethylether acetate (PGMEA). If this condition is not met, the black PDL pattern has a saw-toothed deformation due to the aggregates made by incomplete solubility of the ingredients in the photoresist solution.

Note that this article was modified slightly after publication to fix a µm to mm switch caused by the transfer from word and to attribute a couple of comments correctly to DSCC as well as adding detail about the glass thickness.supply chain.