Vacuums were much on my mind when I listened to the last couple of talks in the DSCC/SID Business Conference in the TV section, given by Jason Hartlove of quantum dot (QD) developer, Nanosys and Rachel Cassidy and James Murphy of GE, which is developing phosphors. Both companies are really helping develop technical solutions to improve the colour quality and efficiency of LCD and other displays.

That’s especially true in TV, which represents not far off three quarters of display production if you measure it in square metres.

Nanosys has been the leader in developing quantum dot solutions for TVs, tablets and monitors. That has initially been to enhance LCD colour performance by embedding the QDs in films which have been used in LCD backlights to extend the colour performance. Although OLED has a strong position in the premium end of the TV market, the TV category is mainly an LCD market. QDs have the advantage that they are very efficient at converting blue light to red and green, with narrow spectral peaks that make it possible to show more saturated colours, extending the colour gamut of the display.

Unfortunately, as is often the case with materials that are reactive with electrons or photons to create light, they are also very sensitive to oxygen and water – the same problem applies to OLED materials. They can also be sensitive to heat. So, the way that QDs are used in LCDs is in a diffuser layer that sits between the backlight and the LCD cell. Blue light from the LEDs in the backlight hit the film and is converted to white by interacting with red and green quantum dots, with some blue light leaking through, so you get white.

It would be more economical if you could just put the QDs directly onto the LEDs themselves as you would be able to use less material, but LEDs get very hot, so that’s not feasible. Nanosys in its early days tried putting the QDs in glass tubes next to the LEDs (it called them Quantum Rails). Others also tried to do this, but it didn’t work very well.

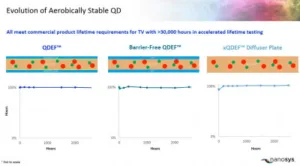

So, the best solution was to put them in a film, away from the heat of the LEDs and Nanosys pivoted to promoting film rather than glass tubes at SID Display Week 10 years ago. Now, the diffuser is a relatively large area, but you have to protect the QDs from oxygen and water, so the diffusers have to be very effective, but the barrier films on both side of the diffuser were more expensive than ideal. The technology was known as Quantum Dot Enhanced Film or QDEF. A number of companies developed this film, including 3M, although that company gave up a couple of years ago.

A development of the way that QDs were used was the idea of QD ‘filters’. I have a particular interest as I was at an event at IFA when I thought of this idea and wrote to Nanosys to suggest it. They ‘pooh-poohed’ the idea in their reply – suggesting that it wasn’t possible, so I was surprised when Hartlove showed a diagram of the idea in his Display Week talk a year later!

My idea was based on an observation that I made at the conference that it was kind of crazy to add loads of red and green light at the back of the panel, using the QDs, only to filter most of it out again at the front of the LCD. If you could leave the light as blue as it went through the LCD cell and then instead of filtering it, you could convert it, it would make the system much more efficient. It’s obvious once you think of it, but I was very proud of the idea at the time!

Anyway, Nanosys worked on the materials to try to enable this approach but you had to get away from barriers. The company worked out how to, effectively, coat each QD in a chemical layer that would shield it from the air. However, there was a problem (well a number, but this was a big one). To get a good result, you have to convert all the light going through the filter layer. That was tricky; quite a lot of the blue light leaked through the red and green pixels unless you made the QD layer very thick and that was expensive. The light leakage spoiled the purity of the colours, killing one of the big QD advantages. The mixing and leakage didn’t matter with a QDEF film as you were going to filter the light later. That QD colour filter approach is probably still being looked at in R&D, but after a year or two of ‘buzz’ it has faded away.

At Display Week this year, Hartlove announced two big developments in reducing the cost of the films. First, the latest materials are much, much more stable in air (which they were working on for the colour filter replacement idea). With that problem solved, the QDs can work in films which can have simple PET top and bottom layers, which are substantially less expensive than barrier films. That’s a good and significant win. If there was no cost increase, everybody would have QDs as there is no real downside. For makers that already have set designs using QDEF, they can just replace that film with the lower cost version and save money.

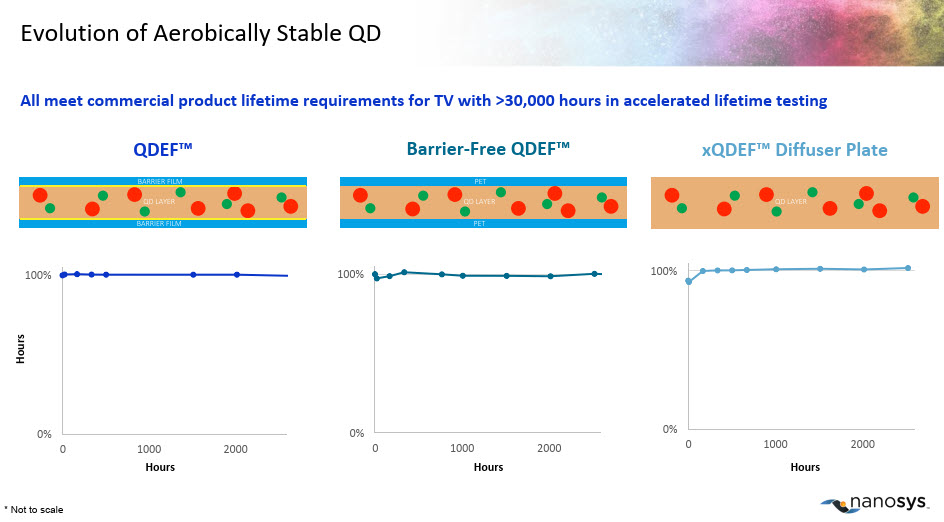

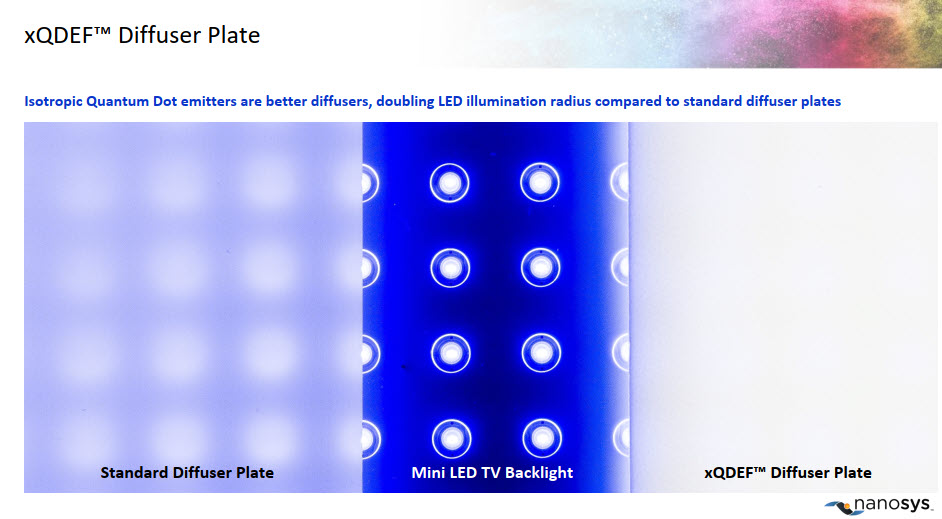

However, the firm has gone one step further and has developed a lightguide plate that puts the QD inside rather than putting them in a separate diffuser film. (the diffuser film usually sits on top of a lightguide plate). That further reduces cost and allows optimisation of the optical stack so that diffusion is claimed to be twice as good as standard diffusers. Technically, it’s still a film, but it reduces the thickness of QD LCDs and is also said to be a better solution for miniLED sets in particular. It’s called xQDEF for ‘eXtruded QDEF’.

At Display Week, Hartlove said that the manufacturing cost of adding QDs to a set is now down to $16 for a 65″ set, whereas the median price of sets in the market with QD is $140 more than those without. In contrast, going up to 8K actually costs the OEM more than the difference in median price uplift for 8K sets, so Hartlove said that set makers can make better margins by boosting with QD than by going up to 8K. (that’s a bit disingenuous – sets with QDs tend to be premium with better audio, more interfaces, better backlights etc, not just the same set with a film. However the overall point is a good one).

Separately, Nanosys announced that it has developed a new green QD material that has the big advantage for some users that it doesn’t use cadmium. It has had non-cadmium based materials before, (as have others) but there was a big performance penalty in adopting them. The new materials are 35% more efficient than the old ones and are said to have colour purity that is very close to the dots containing cadmium (<30nm FWHM for our technical readers. Now those that won’t use cadmium for policy reasons (such as Samsung and Apple) can boost their performance.

Nanosys also announced the acquisition of gl? – a developer of microLEDs but that’s another substantial topic that I’ll return to. (Nanosys Buys Gl?)

However, as I mentioned at the start of this article, Nanosys does not live in a vacuum and that is also true commercially. GE also had some interesting news on phosphors which compete with QDs for wide colour gamut displays, so more of that next week! (BR)