A team of researchers led by Zhe Zhuang within the Computer, Electrical and Mathematical Sciences and Engineering Division at King Abdullah University of Science and Technology (Thuwal, Saudi Arabia) are developing highly efficient red microLED devices.

First a few words of background information.

The color of the light emitted by a microLED is determined in part by the properties of the semiconductor material from which it is formed. Specific examples are that nitride semiconductors such as InGaN can be used to produce blue and green microLEDs, whereas phosphide semiconductors such as AlInGaP can be used to produce red microLEDs. As a practical matter, it is found that the need to combine different types of semiconductors to make a full color microLED device can be both difficult and expensive. There are several reason for this. First, semiconductor material differences can cause a mismatch in the angular distribution of the red and green light emitted by the microLEDs. This, in turn, can lead to a noticeable color shift when the device is viewed from different directions. Second, AlInGaP red microLEDs typically suffer from reduced efficiency when the dimensions of the device are reduced.

Further details regarding this second point are as follows: the amount of red light emitted by an InGaN microLED can be increased by increasing the materials’ indium content. Unfortunately, increasing the indium content also tends to lower the efficiency of the resulting microLED. The reason for this is that there is a mismatch between the separation of atoms in the GaN and InGaN, which causes atomic level imperfections. In addition, damage to the sidewalls of an InGaN microLED induced during the fabrication process can also cause the device to be less efficient.

These difficulties in producing an efficient red microLED were the subject of the research undertaken by the team. A recent article on this topic by the team is entitled “Investigation of InGaN-based red/green micro-light-emitting diodes.” It was published in Optics Letters 46, 1912 – 1915 (2021). A copy of the article can be found here.

Increasing Red Efficiency

In this article, the researchers report successfully increasing red efficiency by a new chemical treatment that removes damage to the microLED sidewalls that can be created during the fabrication process. Stated in another way, the process retains the high crystal quality at the InGaN and GaN sidewall interfaces. The article provides extensive details on the fabrication process by which this is accomplished.

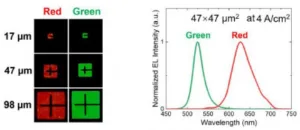

In their work, the researchers created and characterized a series of square InGaN-based red and green microLEDs devices having sizes that ranged between 17 and 98 microns. The article includes a discussion on the techniques used to make the measurements as well as a wide variety of measured data. Key results are as follows: the 47 x 47 mm2 red microLED device emitted light at a peak wavelength of 626 nanometers at 4 A/cm2. The device had an on-wafer external quantum efficiency (the number of photons emitted from the microLED per electron injected into the device) of up to about 0.36% corresponding to an expected absolute external quantum efficiency of 0.87%.

The color of the red microLED is described as near optimum in that it was found to be very close to the primary red color defined by the industrial standard known as Rec. 2020. The researchers noted, however, that the InGaN red microLEDs suffered from severe thermal droop (loss in efficiency with increasing temperature) compared to the green microLEDs. More specifically, a large blueshift of the peak wavelength (~35 nm) and a broad full width at half maximum (? 50 nm) between 2 and 50 A/cm2 were observed in the red microLEDs. Note, however, that the coordinates of the red microLEDs in the CIE 1931 diagram move towards the primary red color with increasing temperature. This movement is opposite to that of the green microLEDs and serves to increase the gamut area coverage in the color space.

The image on the left in the figure below illustrates the emission of red and green microLEDs made in three different sizes. The figure below on the right presents a graph of the normalized emission spectra for green and red microLEDs at one device size.

Left: electroluminescence emission images of red and green microLEDs with the mesa areas of 17 x 17 mm2, 47 x 47 mm2 and 98 x 98 mm2. Right: normalized electroluminescence spectra of red and green microLEDs with an area of 47 x 47 mm2. The current density was 4 A/cm2.

An interesting if not particularly informative video on the ongoing red microLED research at King Abdullah University of Science and Technology can be found at the end of this article.

The next investigations that the researchers expect to undertake include finding means to further increase the efficiency of red microLEDs and to do so at even smaller chip sizes. The team then plans to integrate red, green and blue nitride-based microLEDs to create a full color display. – Arthur Berman

King Abdullah University of Science and Technology, Kazuhiro Ohkawa, [email protected]

Editor’s Comments

We’re used to seeing EQEs much higher than quoted in this paper, so we contacted the author, Prof Ohkawa who said that “Unfortunately, those figures are correct. Even so, those figures are good values compared to others (UCSB reported 0.2% for red, and so on)”.

His group will continue to try to improve the efficiency. (BR)