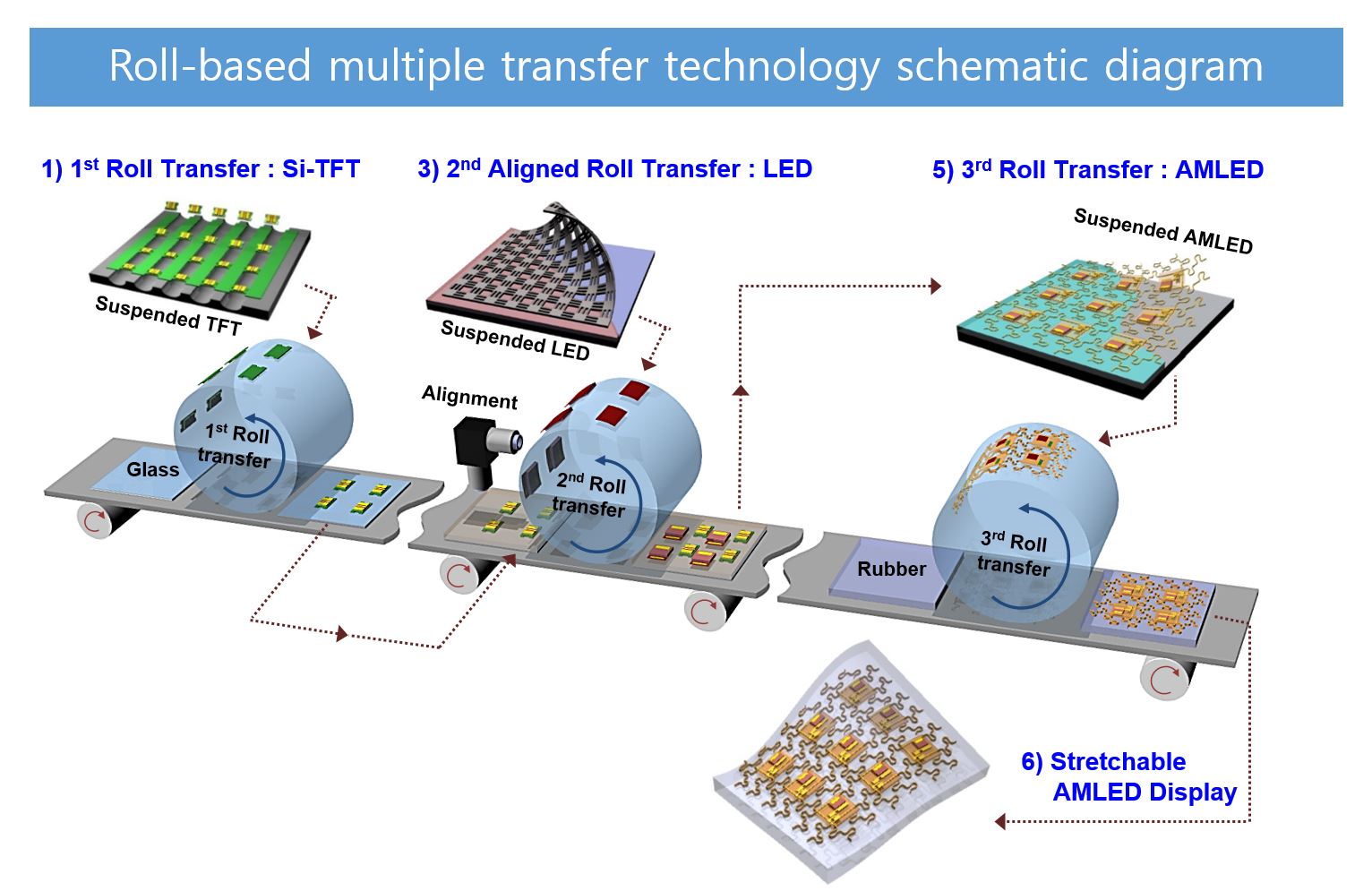

Business Korea reported back in July, that the Korea Institute of Machinery and Materials (KIMM) has developed a process for the transfer of LEDs created by the Nano Applied Mechanics Team at the Institute. The LEDs are reported to use only 50% of the power of bigger LEDs, although they are also described as having luminous efficacy of ‘three times;. The process is described as a roll-to-roll transfer process that can transfer about 10,000 chips per second. The chips are applied to a TFT active matrix for control.

A follow up article by Trendforce included more details of the process which could be used to make stretchable displays. The roll has a disposable transfer film and these are used to capture the TFTs and LEDs which are simultaneously soldered to the substrate. Care has to be taken with the speed and pressure, but the KIMM believes it could achieve good results even if the LEDs were much smaller. It can work on MicroLEDs of less than 100 µm and less than 10 µm in thickness.

The KIMM is reported to have licensed technology for digital signage applications to Lumens of Korea. However, this is based on 100µm thick LEDs onto rigid substrates using solder paste, so is a variation on the CoB technology that is currently under development by LED display makers. The licence for smaller LEDs and flexible or transparent displays will be licensed seperately.

Analyst Comment

We missed this report when it was first revealed, but given the interest in the topic, we thought we’d report it, nevertheless. Although 10,000 chips a second sounds fast, it would take 40 minutes to create an UltraHD panel. That’s not quite the Tact time that makers will want. (BR)