IHS said that although the demand for cover lens lamination and sensor lamination is declining, rising direct-bonding demand for mobile phones is making up the loss. The functional use of adhesives in direct bonding will account for more than half (51.3%) of total area share in 2016, after comprising just 46.2% in 2015.

OCA is more suitable than OCR for use in flexible curved displays and 3D cover glass. In addition, vivid decorative film is now replacing the conventional color ink beneath the cover lens, which requires OCA for bonding. As smartphones from Samsung and Apple will lead growth in the flexible display market in 2017, the demand for decorative film will grow even faster.

Although the overall tablet PC market is declining, Apple, Microsoft and Samsung are now adopting OCR for direct bonding, which is leading to rising OCR demand. In addition, two-in-one tablets with 10″ displays also use direct bonding.

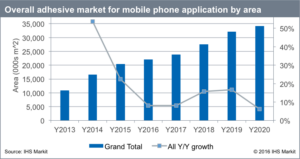

- As average display sizes continue to increase, and with direct bonding continuing to trend upward, the total adhesive market for mobile phones will grow 8% from 20.4 million sq metres in 2015 to 22.1 million sq metres in 2016.

- The market for optically clear adhesives (OCA) used in mobile phones will increase more than 10% per year after 2017, thanks to increasing use of decorative films used for 3D cover lenses, flexible displays and the trend toward more direct-bonding, in which there is an adhesive layer between the touch sensor or cover lens and the display panel.

- The optically clear resin (OCR) market for tablet PCs will grow 30% in 2016, compared to the previous year, since Apple and Samsung both use OCR in their tablet products and the use of direct bonding for larger displays is rising.

- Embedded in-cell and on-cell touch-screen solutions are on the rise, which is changing the touch sensor structures and influencing the use of adhesive materials.

- Curved and flexible displays — featuring 3D cover lenses and decorative film replacing silk-print ink — influences the adhesive materials used.

- Direct bonding is a popular way to make mobile devices thinner and improve display performance.

Analyst Comment

I still meet people that want to explain optical bonding to me, not realising that this technology is old. More than 25 years ago, I was selling CRT monitors that looked really great because they had anti-reflective panels (using λ/4 technology) optically bonded to the CRT. The performance was excellent, but it was expensive! It was particularly tricky because the front of the CRTs was usually curved horizontally and vertically (just horizontally on Trinitron and Diamondtron CRTs and the Zenith FTM was completely flat)