Dr David Arreaga is founder of Ares Materials from Texas which makes films for flexible displays. The films are based on polysulphide which have not been used so far in the flat panel display business. Arreaga believes that flexible and foldable devices will start to appear in Q4 of this year and he said that ‘the age of glass is coming to an end’ (Corning might disagree with that!). Glass has been a key component of LCDs and OLEDs as well as CRTs and PDPs.

Dr David Arreaga is founder of Ares Materials from Texas which makes films for flexible displays. The films are based on polysulphide which have not been used so far in the flat panel display business. Arreaga believes that flexible and foldable devices will start to appear in Q4 of this year and he said that ‘the age of glass is coming to an end’ (Corning might disagree with that!). Glass has been a key component of LCDs and OLEDs as well as CRTs and PDPs.

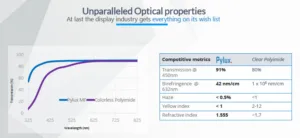

Arreaga quickly went through the pros and cons of different materials including colourless polyimide. Nothing is really suitable, he said. Ares has a material called Pylux which is very flexible and with the optical properties of glass. Birefringence is very low as is haze and the yellow index is very low compared to polyimide. The material is very adaptable in terms of its operating temperature from -60 C to +140 C. The material has 200K cycles of foldability and can be tuned to have different mechanical properties according to the application.

Pylux is said to be very cost effective and can be just $50/m², which is well below the $250/m² for competitors. The company has tried making filters with the material and has also worked with OCA materials.

A new announcement at SID was ‘Easybond’ which is a material that can be used to solve a problem with the current manufacturing of flexible OLEDs.

Arriega said that the Laser Lift Off (LLO) process used to detach flexible displays from the glass carrier substrate is about 75% yield (although some are at “80% to 82%”) but that is well below the 95% yield of rigid displays. LLO is very difficult and the bad yields are killing profits, Arreaga said. This kind or yield problem is especially bad when its at the end of the manufacturing process as all the materials are usually scrap.

Easybond has a mechanical peel off system that makes it a simple process and the target that the company is aiming at >90% yield. It is working with 25 companies and it is working with six product makers. That’s pretty good for a two year old company!

There is a facility in Dallas that can make pre-production materials. Easybond is available now for testing.

The company is in a series A funding round and it expects to be cash flow positive by the end of 2020.