Researchers at IBM say that a ‘major breakthrough’ has been made in the area of carbon nanotube (CNT) transistors – which may replace silicon when Moore’s Law finally fails to deliver.

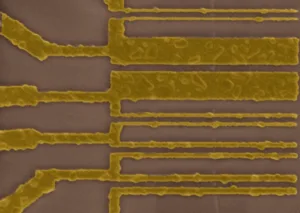

This coloured micrograph shows several transistors made from a single carbon nanotube. The yellow bars are metal electrodes of varying dimensions. The faint vertical line roughly a third of the way in from the right side of the image is the nanotube.CNTs are small cylinders of atom-thick carbon. Their electrical and thermal properties mean that they have the potential to form the basis of circuits that are more efficient and faster than silicon-based ones. However, the increase in contact resistance with decreasing size is a major obstacle to their use.

The IBM team has developed a single-walled CNT (SWCNT) transistor technology with an end-bonded contact scheme. This has led to size-independent contact resistance, to overcome the scaling limitations of conventional side-bonded or planar contact schemes.

Rather than placing the two metal contacts on top of the CNT, as is conventional, the researchers placed them at the ends of the tube. The contacts were made to react with the carbon, to form a different chemical compound. This new SWCNT transistor had a sub-10nm contact length.

The device exhibited a device resistance of sub-30 kilohms and on-current above 15 microampere per tube. The p-type end-bonded contact also exhibited a Schottky barrier (a potential energy barrier for electrons formed at a junction between a semiconductor and metal).

The work overcomes one of the three major hurdles facing CNT transistors. Another is that nanotubes exist in both metallic and semiconducting forms, but only the latter are useful for transistors; engineers must become better at separating the two types. The other challenge is the development of a reliable and non-lithographic way to place billions of CNTs where they are needed on a chip.