Recent reports have indicated that Samsung Electronics and Huawei are aiming to launch smartphones equipped with foldable OLED displays. Meanwhile, display manufacturers are converting the glass materials used in existing substrates and cover windows to plastic, so the durability of plastic materials is becoming an important issue, according to UBI Research.

There are various types of durability tests but the most typical is the folding test, where materials are repeatedly bent and unfolded. During a typical folding test, a mechanical device is used to pivot the rotating plate after fixing an element of the foldable material to the fixed plate and fixing the remaining part to the rotating plate.

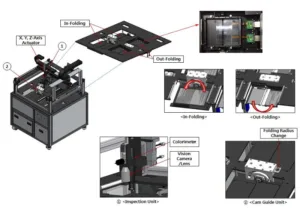

Image: FlexiGO

However, in conventional devices, the foldable material and rotary plate have different axes, so the foldable material moves along the rotation path of the rotary plate, not the original rotation path of the material. To solve this problem, FlexiGO recently developed the Foldy series, a new range of solutions for fold-testing materials.

The Foldy series adds a motion controller that supports the fixed plate and the rotary plate, allowing the fixed plate to move forward and backward so that the foldable material moves along the original rotation path and no other stress is applied to the material. The sliding controller is mounted on the motion controller and the rotary plate performs a motion that allows the foldable material to slide across it.

The solution includes micro vision, surface profiling and colorimetery. Foldy-10 and Foldy-100 products can be used in different test environments. In addition, it is possible to mount an additional inspection system.