Perhaps you have been putting on some old blues records to get you through this turbulent time. It’s a normal thing to feel a little down about the world right now. And some days I feel the same way about blue emitters for next-generation display technology.

Sure, blue LED technology has seemingly advanced light years in the past two decades to reach where it is today. And there is no doubt it is a success story of optoelectronics impacting our daily lives. I urge you, just try to count the number of blue LEDs you interact with on a daily basis.

As we all know, blue LEDs have enabled the LCDs we love (hate) today. They have their drawbacks though. LCDs with blue LED light engines are really a brute force approach to getting colored light to our eyes in a well-controlled fashion. The future of flexible, light weight, efficient displays will require new ways of generating red, green, and blue light.

Of course, OLED has become a key enabling technology when it comes to these future displays, but OLED is not without its drawbacks.

OLED has struggled with blue materials for some time now. They exist, but never quite meet the mark, seemingly always requiring a sacrifice of color, efficiency, or stability. The lack of a satisfactory blue material is one of the reasons OLED TVs are actually white OLED with color filters.

It seems like good blue emitters are just really, really hard to make. The same holds true for blue EL-QLED.

It’s fun to talk about all the progress being made in the world of EL-QLEDs, but the elephant in the room is still blue. WE NEED A GOOD BLUE DEVICE! If blue EL-QLED can advance, it would compete directly with blue OLED (and could provide the blue for QD color filter technology), possibly enabling devices we have only dreamt of. So here I’ll highlight recent progress in Cd-free EL devices that provides a glimmer of hope and a healthy dose of reality on why I’m still singing the blues about blue EL-QLED.

Two of the most recognizable brands when it comes to quantum dots (Samsung and Nanosys) have both reported on their blue EL-QLED progress in the past year. Nanosys presented impressive numbers at SID Display week 2019 with >12% efficiency of a ZnTeSe EL-QLED device with a T50 of about 100 hours at 100 nits. That’s 50% emission after only a few days! And we are celebrating this as a success since most blue QD-OLED devices are far worse than that!

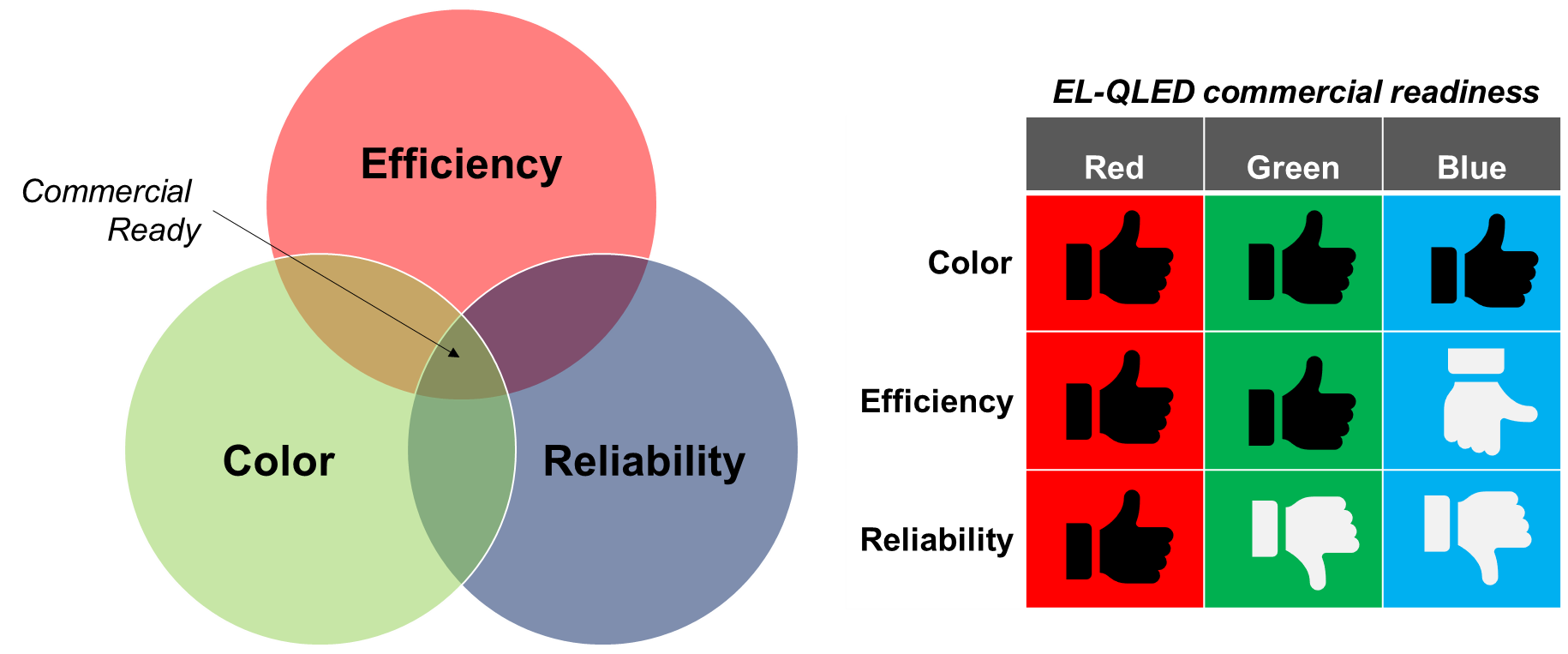

One great feature about ZnSe-based QDs is that they have very pure color emission, with a peak width (FWHM) of around 20 nm. Samsung has also reported they are working on a ZnTeSe alloyed QD with similar properties (narrow peak width, high quantum yield) but have not yet reported any device performance other than to say it is >10% efficient.

ZnTeSe QDs from Samsung’s 2019 QD Forum presentation.

ZnTeSe QDs from Samsung’s 2019 QD Forum presentation.

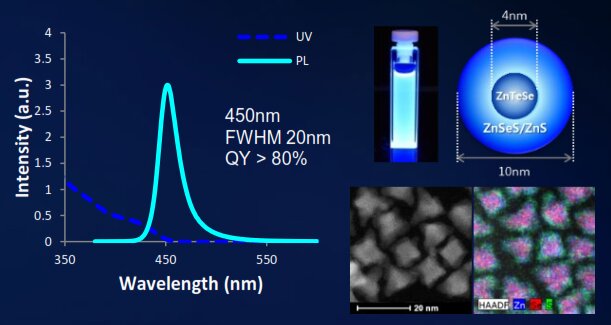

A recent paper from Hongik University details a similar ZnTeSe QD material with nearly 10% efficiency. They also use a unique set of materials in the stack that may help lead to the impressive performance. Chances are the lifetime is poor, but I argue that is ok (for now) as we are making good progress in two other important categories.

The blue EL-QLED device created at Hongik University and the materials used to create it.

The blue EL-QLED device created at Hongik University and the materials used to create it.

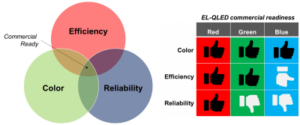

The trifecta of efficiency, color, and reliability is a difficult pinnacle to reach. Many materials fall short in one or more of these categories, but the progress is what is important. Compared to just a few short years ago, the field of Cd-free EL-QLED performance has come a long way in a much shorter amount of time than Cd-containing EL-QLED and OLED. Here is where we stand in these three important categories.

Color: As far as QDs are concerned, there are not many non-Cd materials available today that can meet the color requirements for displays. Zn-based QDs, and InP are among the few that have a narrow enough peak width and tunability in the blue region of the spectrum. So, we as scientists, are limited with what we have to work with. Of course, there are other materials like nitrides that could in theory be a good fit, but there are major challenges in their synthesis that may be insurmountable.

Efficiency: Optimization of QD material and stack design will impact both efficiency and reliability, but efficiency is often the first hurdle to tackle. After all, if it is an inefficient device, it will overheat quickly resulting in premature failure. Champion devices for all three colors are >10%, but only red and green are reaching the theoretical maximum of ~20% (with optical losses).

Reliability: The final hurdle in many new materials is often reliability. QDEF films had to prove themselves in this category, after both efficiency and color were well-established. OLED still struggles in this category (i.e. burn in). Red EL-QLEDs have done very well in reliability tests recently (yes, even Cd-free), but the rest of the colors still have progress to be made – especially blue. I have mentioned before that T50 is only a starting point metric, and T90 or T95 would be better. But then again reporting T95 in minutes is not going to be that informative.

Of course I have over simplified the by providing only three metrics, as there are many other important factors like manufacturability, toxicity (non-Cd would be ideal), and the need/desires of the consumer (cue marketing to make that happen). Regardless, I hope this gives you a view from where I sit… at home… for the foreseeable future.

Here’s to the day we stop singing the blues about blue EL-QLED, and instead sing the triumphant songs of success. – PP

Peter Palomaki is the owner and chief scientist at Palomaki Consulting, a firm specializing in helping companies solve big problems at the nanoscale. His utilizes his expertise in quantum dots and materials chemistry to solve challenging problems with clients large and small.