Russel Kempt is from Nanosys and he started by saying that the company is qualifying its P6 production line that is ‘significantly’ larger than the previous P4 line which can make volume quantum dots (QDs). The next stage is to develop production in Asia.

Russel Kempt is from Nanosys and he started by saying that the company is qualifying its P6 production line that is ‘significantly’ larger than the previous P4 line which can make volume quantum dots (QDs). The next stage is to develop production in Asia.

Nanosys only makes materials for displays and that is a strength, he said. Kempt said that the firm’s price point is very low because the whole process is automated and the firm has a higher yield than others, so its cost is “as low as it can be”.

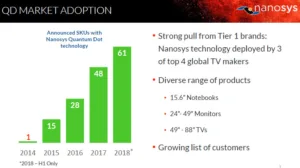

QDs in film (QDEF) has been used in many products with 61 new products this year, alone. Kempt explained how the film works. Partners making the film include Hitachi which makes film using Nanosys QDs.

Nanosys is seeing more design wins

Although Nanosys has high penetration in the premium market (more than 50%), this is just 3% of the overall TV market. TV makers would use more material if it was cheaper and the company is reducing its cost by around 30% per year. Kempt then explained the QDOG system (Will QDOG Have its Day?).

Samsung was expected to show the QDOG technology at SID, for IT applications (which Samsung Display had already shown at ISE (Samsung To Develop QD Glass LCDs)

Kempt then went on to describe the QDCC (QD replacing colour filter) technique that we first reported when it was announced in 2016. (BC19 Nanosys Changes QD LCD Architecture) Nanosys is now sampling its materials to the industry, having worked with ink makers. All materials after QDEF do not include cadmium. No cadmium or heavy metal-based materials are being developed by the firm now.

Moving to microLED, Nanosys is looking at using microLED with QDs for colour conversion and the company has developed inkjet and photolithography-based materials.

Finally, the company is working on electro-emissive QDs which should have a much longer life than organic materials. Nanosys believes that it has been able to learn a lot about the kind of architecture issues that it will have to solve from OLED development and that will accelerate the development.