The final session was started by Dr Mike Hack of Universal Display Corporation (UDC), one of the key suppliers of OLED materials and processes.

The final session was started by Dr Mike Hack of Universal Display Corporation (UDC), one of the key suppliers of OLED materials and processes.

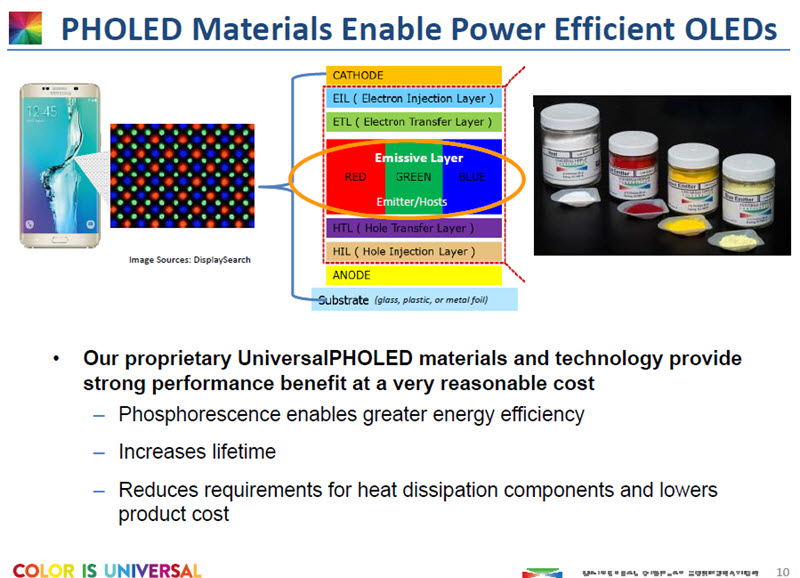

The company supplies phosphorescent OLED emission layers including the host layers for displays and lighting. After many years of OLED of being a challenging technology, it is now becoming mainstream, especially in smartphones, he said.

A key breakthrough was the adoption of the firm’s materials by Samsung for the Galaxy series of smartphones. UDC has bought patents from Fujifilm (2012) and BASF (2016) and a research company (Adesis a contract research organisation (CRO)) to help its strength in OLED materials.

The manufacturing of the materials designed by UDC is done in the US by PPG which makes the chemicals which are shipped to UDC for qualification and subsequent distribution to customers – which includes ‘everyone’ in the industry. There is a big chemistry workforce as well as device physicists in the company’s facilities. The company has a global network of offices.

UDC has 2,530 patents issued and 1,756 pending for a total of 4,286. PPG has sales of $15.3 billion and Hack said that the company is very good at supplying “very pure” materials.

OLED has advantages in some cases for power consumption on TVs and in some applications for smartphones. Display flexibility is a key issue for the future and will be “ubiquitous” in five years or so, UDC believes, and that will drive a lot of demand for new products in both display and lighting. Hack believes this change is what is driving the huge expansion of capex in OLED.

Better efficacy means less power and longer battery life, but also less heat in the system. At around 400 cd/m² with 40% of the pixels lit, the OLED would use, maybe, 40% less power than LCD, he said. At the moment, the deposition process is by vapour deposition, but the materials that UDC currently supplies are compatible with other patterning techniques, Hack said. The company designs complete emissive layer systems based on the choice of colour, lifetime, efficiency and voltage parameters. Effectively, each customer has a custom solution.

The demand for high brightness at up to 1000 cd/m² means very high brightness at the device level. The lifetimes of red and green are very good now, even at 1,000 or up to 10,000 cd/m².

Turning to applications, TV looks good, Hack said, as LG has done a good job. Wearables is a natural market as flexible displays can be fitted to the body. The vision of the rollable display has been around a long time, he continued, but it is really in sight, now.

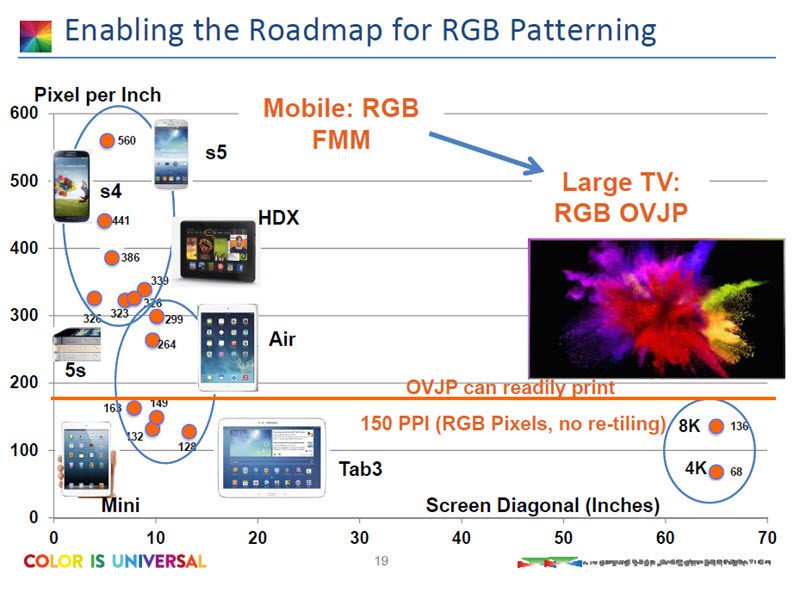

Hack then talked about organic vapor jet printing, a technique for OLED material deposition that was originally developed initially in 2005. The industry is moving to inkjet materials and these have to be dissolved in solvents, and that is problematic, he said. The idea of UDC is to put the current materials into a carrier gas and print them onto the display surface. The vapour jet can create lines of OLED material and can be used to make 55″ to 75″ displays with UltraHD and even up to 8K. The efficiency is now at the same level as vapour depostiion, Hack said.

The company also has an idea to create a two colour OLED system with yellow and blue combined with a green and red filter. The patterning in this approach is also at half the resolution. The red and green can be created with colour filters, but you don’t get the normal power problem with wider colour gamuts as most of the images are created using the yellow and blue. This idea has been around some time and we wrote a Display Daily on it. (UDC Works on Hybrid OLED Approach)

Hack then showed a short video of the OVJP process, which moves a substrate over the nozzles of the machine and can apply multiple layers in a single pass.

Analyst Comment

Last year, UDC was hinting that it might be close to solving its blue problem, but the raising of the two colour OLED system suggests to me that UDC is still some way from a good solution, although, as a public company, it has always been conservative on its statements. Later, in questions, Hack said that although Cynora thinks it should be relatively simple to move the wavelength of the blue it is making (as was stated at the event), UDC’s experience is that what looks like a small change can take a surprising amount of time. (BR)