The first panel session addressed the question “Is Good Enough, Good Enough: Can LCD Persevere?”

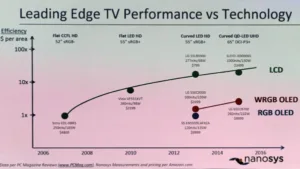

Jason Hartlove, CEO of Nanosys was the first to speak and he showed a slide that looked at efficiency (brightness/power) over time of LCD vs OLED. In 2006, a TV with 250 cd/m² used 185W and cost $4800, now Samsung has sets with 1000 cd/m² at 130W and $3499, and there is an asymptote, he said. OLED is getting better, but it’s not improving fast enough to catch LCD at the moment.

Bob O’Brien of Corning said that he has been coming to SID since 1990, when it was a CRT business. LCD will persevere because it keeps improving and fixing performance issues. Corning has a new Lotus NXT glass that is said to be better for oxide backplanes and LTPS panels. Corning will introduce 0.4mm glass at G8 sizes – which will help set makers to build curved TVs. In questions, he said that LCD still has a long way to go with HDR and thinness as well as improving viewing angles. Even thinner glass is under development for genuinely flexible displays.

Next was HK Chung of Sungkyunkwan University who is a fan of OLED. It was introduced in 2000, and he hoped for commercialisation by 2005, but it took longer and OLED TV is now struggling. Samsung is doing well with small OLED, but is not driving the technology for large sizes. LG is looking “lonely” in promoting OLED TV.

Eventually, Chung, believes that OLED will win because of the relative simplicity and lack of module assembly. Chung said that consumers will eventually realise that LCD is LCD, even if LED backlight were used and sets were sold as LED TVs. Now QD-backlight LCDs are being marketed as Quantum Dot TVs. They are not, they are LCDs. Later in questions, Chung said that consumers still don’t look in enough detail at, for example, motion performance.

Rono Mathieson is VP of TV and related technology at Sharp in the US. There have been great advances in size, resolution, colour, viewing angle, response times, thickness and reliability of LCD. It may not be as good as an OLED in some respects, but it’s good enough for the market and that is critical. Many of the primary attributes of the consumer have been met. There was a scare for the LCD makers a few years ago when OLED was seen as a real threat, but now new backlights, QDs and new phosphors have developed to improve contrast and colour. Black can really be black and white can be very bright – 1500 cd/m² compared to 700 maximum for OLED. (although we saw a small OLED with 1,200 cd/m² at the show – Man. Ed.)

The first question to the panel was about the degradation of QD materials over a product lifetime. Hartlove said that there were challenges, but work with 3M has met the requirements of 50K hours life time. Mathieson said that there are a number of QD approaches, but they are still new and there will be more development, especially putting QDs into or onto LEDs. Phosphors are also developing well and that is helping to boost performance of sets.

Hartlove also covered the environmental issues related to OLED. (This was a big debate at the event).

A question came from Brian Berkeley (once of Samsung and a key SID contributor for many years) about OLED, based on his assumption was that large OLED will take a bigger share. Will there be mask processes or white OLED, he asked? Chung said that he didn’t like the idea of using white OLED because of the efficiency issues, but in reality white OLED is very flexible in producing multiple sizes from a single machine as well as supporting multiple resolutions. That gives advantages in the manufacturing process.

Industry veteran, Bruce Berkoff, asked how AMOLED could compete with the huge capital investment of $180 billion in LCD, with only one real player at the moment? Chung said that it is a David vs Goliath situation. However, AMOLED can really make plastic “roll up” displays and that would be the key long term differentiator.

Another question was about roll to roll (R2R) display using very thin glass. O’Brien said that there were challenges in glass, but there are also a lot of other challenges in moving to that kind of process. Corning is working on it, but it will take several years.