On October 24th, Barco introduced a new LCD videowall system it calls UniSee. According to Barco, this system is “revolutionizing the LCD video wall experience.” This bit of marketing hyperbole may not, actually, be too far from the truth.

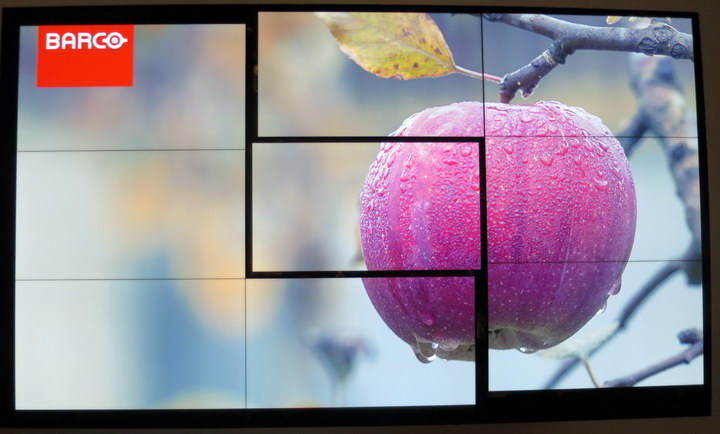

3 X 3 array of Barco UniSee LCD panels. The black area around the array is not a frame but a gap to allow access to the mounting system. This gap would normally be covered with trim pieces in a permanent installation. The hot spot is from the flash used to take the picture. (Credit: M. Brennesholtz)

3 X 3 array of Barco UniSee LCD panels. The black area around the array is not a frame but a gap to allow access to the mounting system. This gap would normally be covered with trim pieces in a permanent installation. The hot spot is from the flash used to take the picture. (Credit: M. Brennesholtz)

I had a chance to see the UniSee system in New York the day it was introduced and talk to the Barco people there. Visually, the thing that struck me first about the 3 x 3 array of UniSee panels on display was the very narrow gap between the adjacent LCD panels. Barco calls this NoGap technology and that isn’t quite true – there is still a visible gap between adjacent panels, unlike direct view LED tiles or rear projection cubes where the gap can be completely hidden. The visibility of the gap, however, is significantly reduced compared to the gap between images seen on other tiled LCD videowall displays that I have seen.

There is no bezel around the individual Barco panels. This allows a narrower pixel-to-pixel gap than is possible with conventional LCD panels with bezels and designed for tiling. According to the Corwin Hamm, Business Development Manager – Barco Control Rooms and Virtual Reality Solutions, the pixel-to-pixel gap in the UniSee system is 1.09mm. He added that the best (i.e. narrowest gap) of the Barco competitors use 0.9mm wide bezels around the individual LCD panels, for a minimum possible pixel-to-pixel distance of 1.8mm. This minimum distance is not realistically achievable, he said, because there needs to be space between the adjacent tiles to provide a tolerence for installation and allow for panels to be removed for service (and also to allow for thermal expansion in use – Man.Ed.). The minimum distance, he said, was about 3.0mm pixel-to-pixel in UniSee’s competor’s systems.

Barco UniSee array with gaps opened up to allow the central panel to be serviced. (Credit: M. Brennesholtz)

Barco UniSee array with gaps opened up to allow the central panel to be serviced. (Credit: M. Brennesholtz)

The very small gap between adjacent panels in the UniSee system would not normally allow the removal and replacement of a panel without disassembling the entire array if a conventional panel mounting system (e.g. VESA) were used. This is especially true since the vulnerable edges of the LCDs are not protected by a bezel in the UniSee system. Instead Barco has designed a panel mounting system that allows gaps to be opened up between panels to allow service. This can be done even while the array is operating, as shown in the image.

Meko’s Matt Brennesholtz opening a gap in the UniSee array with a long handled Allen wrench. The tile he is working on is showing the rear of a UniSee panel on a 1:1 scale. (Credit: M. Brennesholtz)

Meko’s Matt Brennesholtz opening a gap in the UniSee array with a long handled Allen wrench. The tile he is working on is showing the rear of a UniSee panel on a 1:1 scale. (Credit: M. Brennesholtz)

When a panel is to be serviced, first the gap to the right of the panel to be serviced is opened and the entire adjacent column of panels is moved to the right and up with a long handled Allen wrench after unlocking the mechanism. I was told that Barco has tested this mechanism on a system with panels stacked 10 high. While this is said to be a little harder than moving the column of three panels I moved, I was told it is still not difficult. After all of the columns to the right of the panel to be serviced are moved, a lock is adjusted on the panel to be serviced. This allows panels above it to be lifted and moved to the right, the panel to be serviced to be lifted and moved part-way and the panels below it to remain stationary. When servicing the panel is complete, gravity helps return the panels back to their original positions with sub-millimeter precision. Clever.

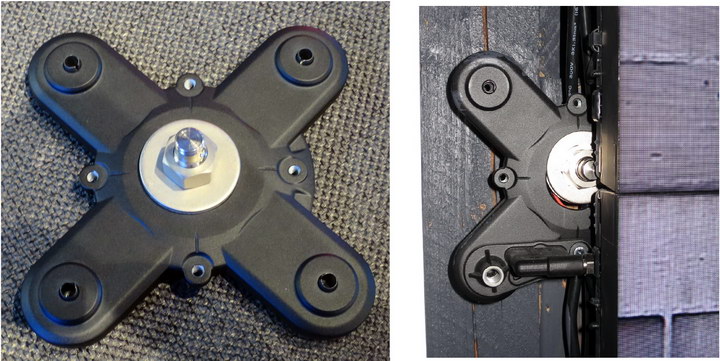

The UniSee system is intended for permanent installation in applications such as control rooms; board rooms and other high-end meeting rooms; and corporate lobbies, reception areas, experience centers or branded showrooms. UniSee is not intended for the rental and staging market. The first step in installing the system is to attach one mounting bracket to the wall at each intersection of the array. This initial bracket installation need not be precise since after installation the brackets have X-Y-Z adjustment capabilities and can be adjusted to the exact position needed.

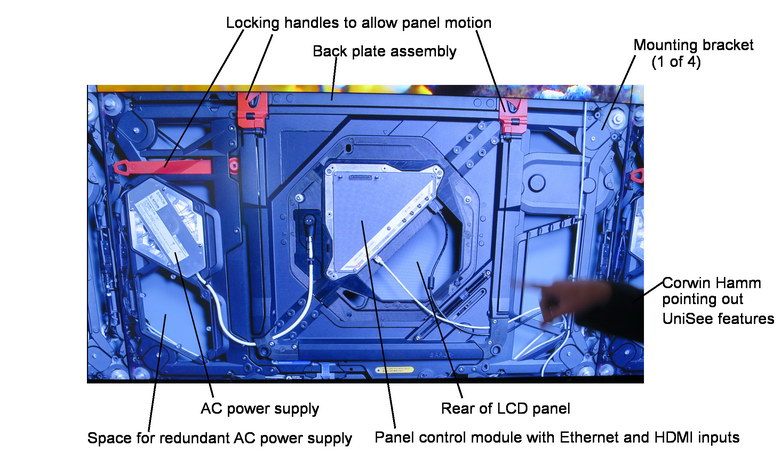

After the mounting brackets are attached to the wall, one back-plate assembly for each panel is attached to the mounting brackets. These back-plates hold both the panel power supply and the panel controller. Finally, the panel itself is installed. All installation and maintenance of the system is done from the front and the array can be installed against a solid wall.

The whole system is fanless, leading to a completely silent system. There are actually three options for the AC power supply: a single AC supply per panel, as I saw demonstrated in New York, a dual AC supply for each panel for redundancy or an external supply.

Left: The UniSee installation bracket is used at the corner of every panel. Right: Installation bracket visible between the UniSee array and the white wall. (Credit: M. Brennesholtz)

Left: The UniSee installation bracket is used at the corner of every panel. Right: Installation bracket visible between the UniSee array and the white wall. (Credit: M. Brennesholtz)

The panels used by UniSee are 55” FHD (1920 x 1080) panels manufactured by Barco with a brightness of 800 cd/m² and a static contrast of 4000:1. The panels use direct-illumination LED backlights but the individual LEDs cannot be modulated separately so there is no dynamic contrast enhancement. Backlight life is specified to be 100,000 hours, or 11.4 years of 24/7 operation, compared to the 60,000 hours that is typical of competitor designs. According to Hamm, the fact that Barco is the only LCD videowall manufacturer that also makes its own LCD panels gives them an edge by allowing Barco to have complete control of both the design and the manufacturing quality of the LCDs.

The panels are said to have a 95% center to edge uniformity, i.e. the edge brightness is 95% of the center brightness. The intra-panel color and brightness is calibrated and pre-set at the factory and is not varied in the field. Two color/brightness sensors in the diagonal corners of each panel allow the system to auto-correct the overall array color and brightness uniformity in real-time. After servicing when a panel is replaced, the system auto-corrects the entire system for the new panel.

IR sensors in the four corners of each display module allow the finished array to auto-configure itself. It is not necessary to indicate the location of individual panels when setting up the array. If a non-standard array size or shape is used, it is necessary to tell the array controller how you want the input video mapped to the array: full sized, stretched to fit, etc. One array controller can control an array of up to 50 UniSee panels, e.g. a 7 x 7 array could be controlled by a single controller.

Image of the rear of a Barco UniSee Array, as shown at a 1:1 scale on one tile of a UniSee array. (Credit: M. Brennesholtz)

Image of the rear of a Barco UniSee Array, as shown at a 1:1 scale on one tile of a UniSee array. (Credit: M. Brennesholtz)

Control of the array is via Ethernet and each panel has an Ethernet input and output for loop-through control. Video works on the same principle and there is a 4K loop-through system. This allows the array to accept a single 4K input and as it loops through the entire array, each panel selects the correct portion of the video, depending on its position in the array as determined by the auto-configuration. I was told this video loop-through system was tested on 4×4 and 5×5 arrays and, of course, I saw it working on a 3×3 array. Presumably it also works on larger arrays, such as the 7×7 array that can be supported by a single controller.

The UniSee system is HDCP-compliant and can show HDCP-encrypted video. Each module has two DisplayPort inputs, two HDMI inputs and one HDMI output. In a normal installation, one HDMI input and the HDMI output would be used to daisy-chain the video. If an end-user wants to break his video down for the individual modules in the tiled display with an external controller, he can use either the DisplayPort or the HDMI input. The modules are also VESA-compliant but Barco strongly recommends using the proprietary UniSee mounting system.

The Barco UniSee LCD panels are manufactured by a Barco factory in Taiwan and the optical, electronic and mechanical components come from a variety of sources. Final assembly of the UniSee system is done in Belgium.

Each UniSee module has a MSRP of $8500, including the panel, mounting system, power supply and panel controller. This price includes a five year warranty. In addition, you must buy one UniSee controller for every array. Hamm said Barco has begun shipping UniSee modules to distributors and he expects the first end-user installations to be in January, 2018.

Barco UniSee modules showed a narrow gap, excellent registration across the gap and high resolution, making them appropriate for a wide range of high-end applications. (Credit: M. Brennesholtz)

Barco UniSee modules showed a narrow gap, excellent registration across the gap and high resolution, making them appropriate for a wide range of high-end applications. (Credit: M. Brennesholtz)

Analyst Comment

The 3 x 3 UniSee array I saw in New York looked good, very good. Uniformity was excellent, color and contrast were good even in the well lit demonstration area and the resolution was fine. The low visibility of the gaps between the modules was a big improvement over competitive LCD arrays I have seen. I would say this system is appropriate for all of the markets Barco is targeting. With the narrow gap, long life and easy maintenance of the UniSee modules, I can see the system giving rear-projection cubes a run for their money in the control room market. –Matthew Brennesholtz

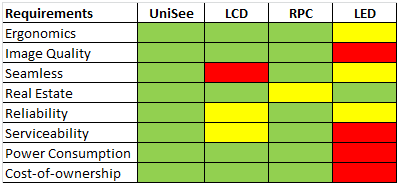

The gravity-based system is very similar to a mechanism that Barco also uses for some of its LED products, so alt Barco emphasised that there are significant advantages over LED displays for this kind of display in a control room as LED displays can suffer from dead pixels which, in some applications, is simply not acceptable. Further, getting good grey scale performance out of LED at the low brightness of control rooms is very tricky. In its press FAQ, the company provided this useful comparison of the pros and cons of the different technologies. Given that Barco also supplies RPC and LED, it should be in a good position to understand the different technologies.

We have reported on some of the problems caused by extremely thin bezels in the past, and when LG showed its finest bezel panels first at Gitex, three were visibly broken. No bezels at all will mean great care will be needed at installation, but the care, we would expect, has to be about the same as that taken for LED modules if you want truly seamless images. We plan to get more on this technology in a follow up article. (BR)