All we analysts love a teardown. It’s great to see how things are put together in real detail. It’s the modern equivalent of the ‘cut-away view’ that I loved as a youngster. At Display Week, I saw what I thought to be a ‘teardown on steroids’.

I met with Eric Virey of MT2 Strategies LLC at the event and he explained that after a lot of work on the microLED market that Yole has done over recent years (and that we have regularly reported on), they wanted to move to cover the miniLED backlight market and understand what is going on there. However, that market is very broad, there are many different ways to configure a miniLED backlight. The maker has to choose the type of LED, the number of zones, the number of LEDs per zone, the driving method, how to connect everything and all the variations in the optical stack. So the firm decided that they needed to look in real detail at what was being done in the market today.

Yole has other companies in the group including System Plus Consulting that specialises in teardowns, reverse engineering and cost simulation. It also has Pis?o that is an optics test lab that could measure the performance of the elements in the optical stack. It also collaborated with DXOMARK, that I wrote about on Tuesday (Everybody Knows MiniLED has Bigger Halos than OLED, Don’t They?) and that looks at performance testing from the user perspective. The four companies combined to look in detail at what was happening in five miniLED products:

- Samsung’s Neo QLED 65″ TV

- TCL’s X92 85″ TV

- Samsung’s Neo G9 49″ monitor

- Apple 12.9″ iPad Pro 2021

- Skyworth Q72

Two units of each were purchased and one was sent to DXOMARK to test, while the other was submitted to SystemPlus and Pis?o. While DXOMARK looked purely at the external optical performance, Pis?o tested the performance of the backlight at different point in the stack before it was fully disassembled.

Different Products – Different Approaches

The five products represented different approaches and included TVs, a monitor and a tablet. They were compared with each other for performance and also with reference displays such as the Sony BVM-HX310 dual layer LCD. There is a big variation in the kind of construction used by the different products. For example, Samsung’s 65″ 8K QLED has 12,096 LEDs, each of 220 x 400 µm and uses 8mm spacers to keep them separated from the diffuser layer, so there is some room for the light to diffuse and become more homogenous. The set uses 336 miniDriver chips and 8 controller chips to manage the LEDs. The same LEDs and minidrivers are used in the Neo G9 monitor, but there are just 4096 LEDs in 2048 zones driven by 512 minidriver ICs. That’s more than in the TV, but the bigger controller chips are not used. The monitor is curved, so the backlight is made from three panels, side by side.

TCL, on the other hand, has highlighted its 0D technology, in which it has emphasised there is no gap between the LEDs and the optical stack – a design choice intended to keep the set very slim. However that means that the set has to have more LEDs to achieve reasonable unifomity as the light doesn’t have the space to diffuse. The SystemPlus found that there are eight times more LEDs (96,000) in the backlight of the TCL unit and no spacers at all. The 150 x 500 µm LEDs are driven by a passive matrix system using 24 Macroblock drivers.

Backplanes are a Challenge

Using a matrix on the backplane has its own challenges as you would ideally make a single substrate rather than using a modular PCB approach. BOE, Virey explained to me, as an example, wanted to use a single glass sheet with an active matrix for the 65″ miniLED used in the Skyworth set. That was a particular challenge because ‘pick and place’ machinery that puts all the (20,736 in 2304 zones) LEDs on the glass sheet are typically limited to placing on boards that are around 20″ (500mm) wide, Virey explained. To put the LEDs on the active matrix glass, BOE worked with Rohinni to develop a new machine to allow placement. (BOE has a JV with Rohinni called BOE Pixey I Saw It, but I Didn’t Understand It – editor).

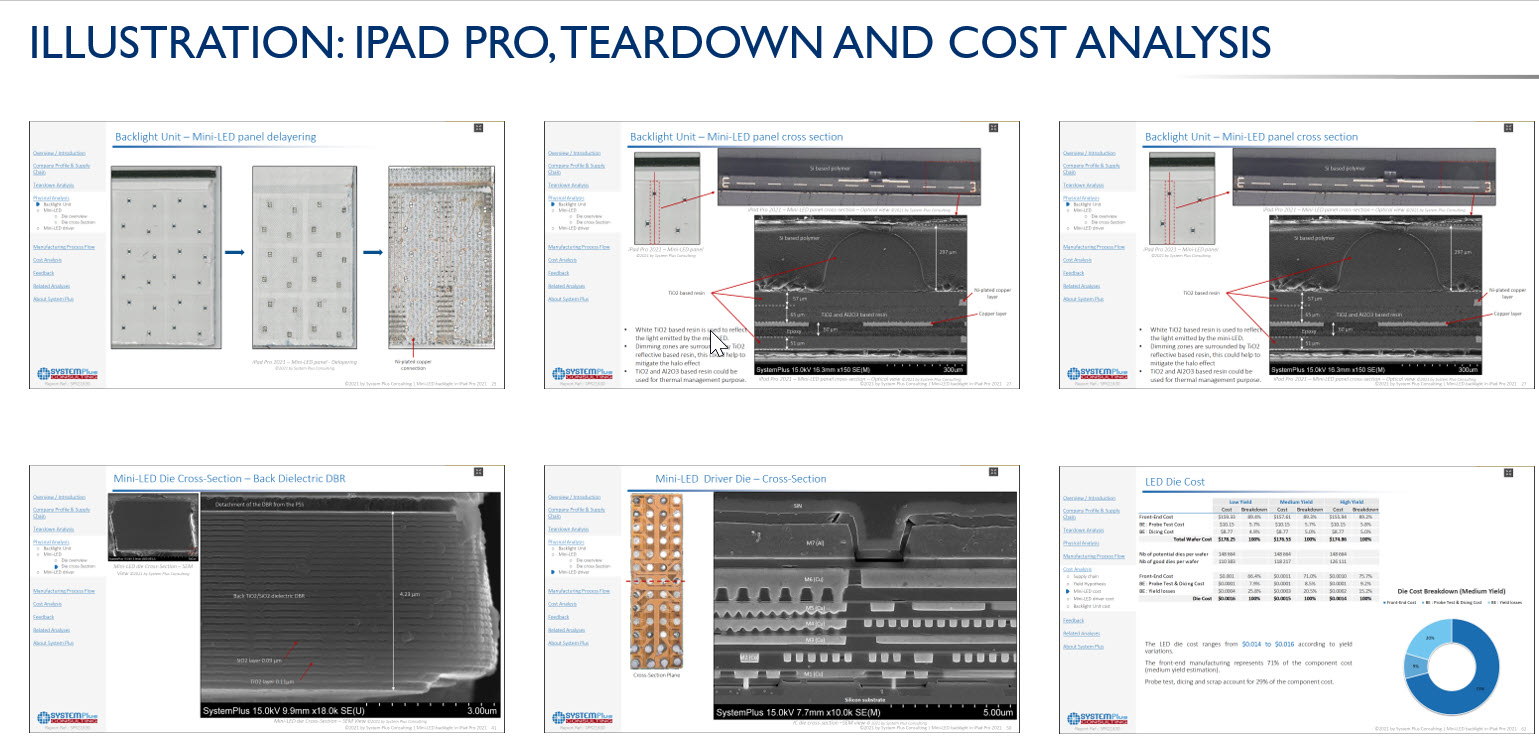

Earlier in the week, we looked at the result for haloing that DXOMARK had found on the Apple iPad Pro 12.9″ and it was interesting to see the detail of the backlight in the final teardown. While DXOMARK showed us the comparison with an OLED tablet, Yole also has a comparison with the Sony BVM monitor and Samsung TV that shows that the Neo QLED TV and the iPad Pro (which have similar performance) actually had lower black levels where there is no illumination, than the Sony monitor. However, both had more haloing than the broadcast monitor. Piseo also looked at the backlight alone and found a surprising level of crosstalk within the LED zones.

One of the aspects of the report that intrigued me at the meeting with Virey was the level of detail in the teardown, which includes SEM images of the cross sections of the LEDs and drivers to fully analyse the components. That, of course, means that the firm can really drill down to build extremely robust cost models for the different approaches to miniLED display making. It should allow very good estimates of the likely cost of different approaches and that is going to be a critical, or perhaps the critical point for miniLED LCD market development going forward.

Thanks to Yole Dèveloppment for the material presented.(BR)