Display Materials, Manufacturing and Components -Green lasers are a key element for all-laser based displays and other markets. In a recent visit with CQ Laser Technologies, we have learned that they have now transferred production of their green laser to China, where customers will soon be using them in projection displays.

The technology behind the company was developed by CQ Xu, a professor at McMaster University in Hamilton, Ontario. In a presentation he gave at Projection Summit in June 2013, Professor Xu noted that green lasers were (and still are) the main bottleneck in the development of a wider scale industry that is looking for these sources. They are much more expensive than red or blue lasers and are often much more bulking, making them unsuitable for many applications. Plus, most are not very efficient.

In our meeting at McMaster University, Xu explained that they have developed a very compact green laser module using second harmonic frequency generation to produce the green light. Their approach solves some fundamental manufacturing alignment problems that Xu believes will usher in a new class of green lasers that are much less expensive (10s of dollars per optical Watt) and meet the output power, size and efficiency (15% wall plug efficiency) requirements the market demands.

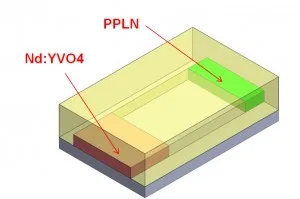

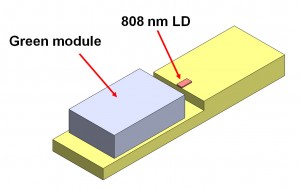

The CQ Laser solution is a mini laser that outputs about 1 optical Watt at 532 nm in a very small 1cc package. Inside this package are two components, a pump laser diode and a green module. The green module contains a Nd:YVO4 waveguide and a frequency doubling crystal (PPLN – periodically poled lithium niobate). The 808 nm pump laser illuminates the Nd:YVO4 laser crystal to create laser light at 1024nm. The PPLN frequency then doubles it to 532nm. The key for high power, stable performance is the very good thermal control they have achieved, explained Xu.

1W of green will typically be enough (when coupled with 1W red and blue lasers) to create a projector with about 100 lumens of white light output. As a result, a single laser is suitable for a pico projector application. But other applications will need much more optical power. A home theater projector will need perhaps 30 RGB Optical Watts while a cinema projector can need as much as 1000 RGB optical Watts.

1W of green will typically be enough (when coupled with 1W red and blue lasers) to create a projector with about 100 lumens of white light output. As a result, a single laser is suitable for a pico projector application. But other applications will need much more optical power. A home theater projector will need perhaps 30 RGB Optical Watts while a cinema projector can need as much as 1000 RGB optical Watts.

Xu says their customers are not focusing on the cinema market, but rather the home theater market, particularly in China. To get there, Xu says it is easy to couple ten 1W green lasers into fibers to deliver to the optical engine.

CQ Laser Technologies is in production now with these lasers in a 4K sq. m facility in Nanjing, China.

Other markets the company has its sights on include the lighting industry (specialty or architectural lights), chemical plants (safe laser lighting), mining (another safety oriented application) and security (no EMI); laser designators, medical (photo dynamic therapy) and more. – Chris Chinnock