Display Components – Cambrios CEO John LeMoncheck was enjoying himself last week at CEATEC, where his company was showing off “Mercury”, the new generation of its ClearOhm silver nanowire (AgNW) ink, along with end-user products.

The current generation, “Jupiter”, is making significant in-roads in the transparent touch-screen market still dominated by Indium tin oxide (ITO).

In a confidential telephone briefing held the week before CEATEC, LeMoncheck and executive consultant Sri Peruvemba told me that AgNW was also beating back the challenge of metal-mesh (MM) technology, a competing transparent metal-conductor technology. LeMoncheck said that early this year producers of metal-mesh sensors aggressively took orders but could not deliver the quantities promised. As a result, he said, penetration of metal-mesh products is declining, while that of AgNW products is increasing.

Quite apart from the ability of metal-mesh suppliers to deliver as promised, LeMoncheck said, is that AgNW is the only technology that can be used for flexible “GF1” sensors – those that use only one layer of patterned film instead of the conventional two layers. GF1 shipments are slated to rise from about 90 million units in 2013 to over 300 million in 2018, according to DisplaySearch.

Also, said LeMoncheck, the typical pitch of standard MM transparent films is 100 to 200 microns, which is not compatible with displays having pixel pitches of around 30 microns, according to an analysis by Synaptic.

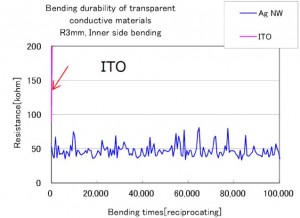

A great benefit of silver nanowires is that the combination of silver’s inherent ductility and the very small diameter of the nanowires give AgNW films remarkable bendability. In testing done by Nissha Printing, the resistance of an AgNW film did not increase after being bent around a 3mm mandrel 100,000 times. ITO, which is known for its brittleness, fails this test almost immediately. (See figure.) Peruvemba commented that Cambrios is delighted to see products such as Samsung’s Galaxy Edge phone, with an OLED display that wraps around the edge of the phone. (Samsung invested an additional $10 million in Cambrios last year.)

A great benefit of silver nanowires is that the combination of silver’s inherent ductility and the very small diameter of the nanowires give AgNW films remarkable bendability. In testing done by Nissha Printing, the resistance of an AgNW film did not increase after being bent around a 3mm mandrel 100,000 times. ITO, which is known for its brittleness, fails this test almost immediately. (See figure.) Peruvemba commented that Cambrios is delighted to see products such as Samsung’s Galaxy Edge phone, with an OLED display that wraps around the edge of the phone. (Samsung invested an additional $10 million in Cambrios last year.)

This year, Cambrios increased the production capacity of its Jupiter ClearOhm ink to 175 thousand liters per year (enough for 700 million smartphones), up from 22 thousand in 2013.

LeMoncheck made two big announcements at CEATEC. The first covered the introduction of the Mercury ink, which produces thinner nanowires than Jupiter. Mercury nanowires are only a few silver atoms in diameter, which is thinner than a strand of DNA. The result is 25% less haze in bright ambient light. Products using Mercury-based sensors should come to market in 2015.

The second announcement was that TPK, the world’s largest maker of touch panels, according to Peruvemba, is significantly expanding its commitment to ClearOhm.

At a recent Pepcom press-and-analysts event in New York, a spokesperson for Lenovo (which is a user of ClearOhm-based touch screens) told me that Lenovo regards all of its new portable computing devices – not just tablets and 2-in-1s – as touch products. Touch is obviously mainstream in phones and tablets, but it will soon be so in notebooks and, to some extent, in monitors.

The Cambrios wave is getting bigger. – Ken Werner