One of the most attractive ways to create an augmented reality image is to simply have a thin, transparent waveguide in front of the eye that can display the desired images or symbols.

AR eyewear from Vuzix and Microsoft (who called theirs “HoloLens”) both appear to use a surface relief grating (SRG) approach to extract the image from the waveguide. Alternatively, DigiLens Inc. uses a Switchable Bragg Grating (SBG) approach that delivers major benefits over the SRG technology. Last year the company established volume production of its technology on avionic head-up displays (HUDs) and is now demonstrating products in personal eyewear.

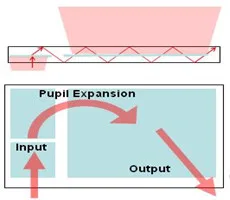

Waveguides are in common use today as LCD backlights. Here, LED light is injected into the waveguide, bounces around via total internal reflection (TIR) and is “extracted” to create a uniform illumination source. The extraction mechanism is a series of etched diffraction dots that essentially “frustrate” the total internal reflection and allow the light to exit perpendicular to the waveguide.

With augmented reality eyewear, you are not injecting and extracting LED light but an RGB image. This is a much tougher problem to solve.

Waveguide optics employing SRG technology originated in Nokia’s Research Labs about 10 years ago. The principle developers were Tapani Levola and Pasi Saarikko, who, with the demise of Nokia Research, later joined Microsoft. Their most recent filing (#8885997) for Microsoft uses multiple colored waveguides “optimized to different colors”. This is very likely the “HoloLens” display famously launched two weeks ago with great acclaim. Before Nokia was acquired by Microsoft in 2014, Vuzix also licensed the SRG approach, using a microdisplay-based engine to inject the image into the graded index waveguide. Intel’s $25M investment at the end of last year and Vuzix’s upgrade to Nasdaq last week, was expressly based on the dream of delivering waveguide optics in consumer wearable eyewear. Vuzix appears to be the only exception to Microsoft’s control of the SRG technology.

A graded surface relief grating is actually more complicated than it sounds. It is a series of nanometer-scale structures that are designed to:

- Extract a full color image from the waveguide

- Provide some lensing to create a virtual image (pupil expansion)

Basic Configuration of Waveguide-Based Augmented Reality Display

These patterns must be holographically defined and then etched into the glass waveguide. The technology works well and for the M100, produces a field of view of 15 degrees and an image that is the equivalent of a 4 inch display at a distance of 14 inches. Specs on the Microsoft Hololens are not yet available but some journalist’s reported a “small field of view”.

Nokia’s Exit Pupil Expanding Technology is at the Heart of Vuzix Next Generation Display

Nokia’s Exit Pupil Expanding Technology is at the Heart of Vuzix Next Generation Display

DigiLens has developed a different approach based on gratings made of liquid crystal photopolymers. These are patterned into more complex optical elements that can also be turned on and off. The company calls them Switchable Bragg Gratings (SBG).

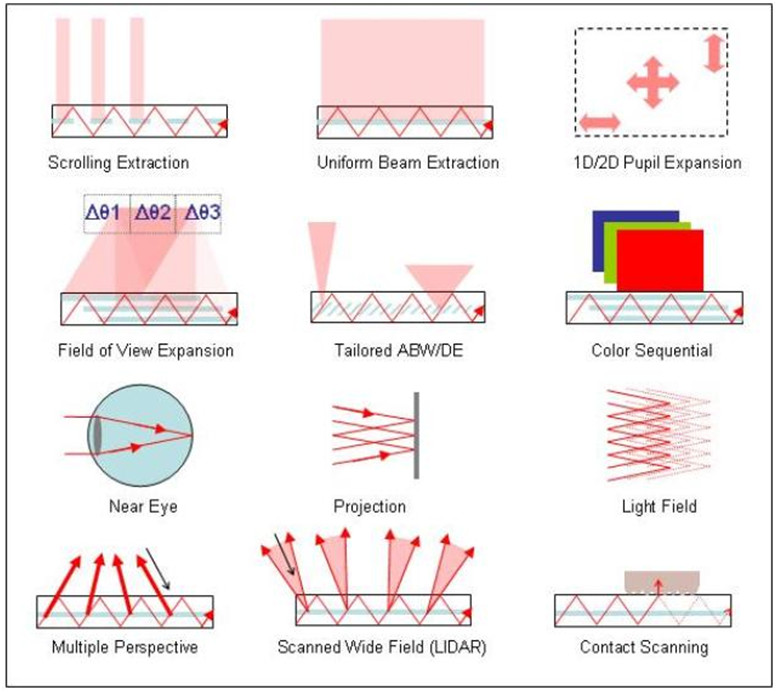

“In the world of FPGAs, designers create the functionality they need by adding IP cores – tested bits of hardware circuitry that can be used as building blocks to create the desired system solution”, noted Jonathan Waldern, founder and CTO of DigiLens. “We offer the analogy in the optical world – IP Optical cores. These are optical building blocks like lenses, beam splitters, EPE’s and speckle mitigation elements that can be combined as the designer needs. They are all holographically defined and work on diffraction not refraction, so they are also extremely flat”.

Summary of Digilens IP Cores for Waveguide Output Functions

Summary of Digilens IP Cores for Waveguide Output Functions

The company has been working for 10 years in competition to Nokia, but differs in that its roots were in LC material science. In this case, it is the very high index materials they have developed which allows thin SBG based waveguides to carry and extract much wider field of view images to the user, compared to SRG based waveguides. In comparison to an SRG, the SBG technology has:

- Thinner waveguides

- Wider Field of View

- Higher efficiency

- A single layer “multiplexed” with optical functions

- Switchability

All of these attributes are exactly what designers of AR eyewear desire. For example, the FOV of an SBG element is about 40 degrees for color applications and up to 60 degrees for night vision monochrome applications – double what is possible with SRG technology. In addition, SBG’s have nearly 98% efficiency, which means a brighter display and less power consumption.

The ability to switch optical cores on and off is profound. This could be used for example, to change the focal length of the virtual display to move the apparent image further or closer allowing “Light Field Display” holographic rendering. It can also allow the integration of eye tracking laminating a tiny eyesafe laser and sensor to the waveguide.

Concept of Personal Eyewear using Digilens Switchable Bragg Gratings and Corning Willow Glass for a Curved Waveguide Solution

Concept of Personal Eyewear using Digilens Switchable Bragg Gratings and Corning Willow Glass for a Curved Waveguide Solution

“We have also created plug-in for common optical design tools like Zemax to be able to model SBG elements as they are so unique”, commented Waldern. This makes it much easier for customers to design the solution they want and quickly allow us to prototype it for them”.

The IP cores are mastered using a special holographic exposure technique. Once done however, inexpensive copies can be replicated with very high yield and with only a 0.1% loss in performance. “We have been working very hard over the last year to establish this duplication quality on our production line – something we are very proud of”, Waldern continued.

In the alternative SRG approach being pursued by Microsoft and Vuzix, as the surface relief nano features decrease in size and increase in complexity, the cost and yield of duplicating parts greatly reduces quality in terms of haze, which severely impacts display contrast. “The only alternative for SRG developers is to uniquely etch the parts individually, using silicon wafer tools. This is the standard today, as SRG manufacturing to the quality needed for wide field of view color display waveguide optics remains unproven”, concluded Waldern.

Analyst Comment

With the maturation of waveguide-based imaging systems using both surface relief gratings and switchable Bragg gratings, it seems likely that a whole new class of display capability is destined to roll out in commercial, professional and consumer markets in the next few years. And the exciting part is that this is just the beginning of what these technologies can offer. – Chris Chinnock