You could make a case for Transparent Flexible Conductors (TFCs) based on thinness, lightweight and ruggedness even when they are being applied to displays with rigid substrates. Now that flexible displays are entering the marketplace in significant numbers, the case becomes even stronger.

TFCs compete on a combination of cost (low is good), sheet resistance (measured in ohms per square; low is good), transmittance or transparency (high is good), lack of coloration (none is good), haze (the lower the better for most but not all applications), degree of flexibility (measured by the diameter of a mandrel around which the film can be bent), and maintenance of sheet resistance with repeated flexing.

The first technologies in the market were fabricated metal matrices and silver nanowire (AgNW) inks. AgNW inks have taken the lead because metal matrices have a regular pitch that produces moire interference with the pitch of the pixels unless the matrix is especially designed for each display, and their relatively large feature size means they can’t be used with displays having very fine pixel pitches. AgNW patterns are random and can be used with virtually any pixel pitch, with the silver wires from some makers now so fine that they produce very little haze in bright sunlight. Cambrios is the current AgNW leader.

However, as we saw at Display Week, other ways to play the game have already escaped from university labs and corporate skunkworks. Here, in no particular order, are the entries that appeared on the show floor.

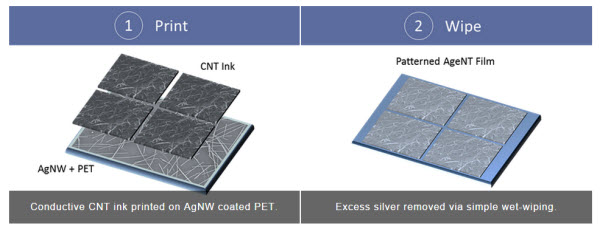

Richard Jansen, VP of Sales and Marketing at SouthWest NanoTechnologies (SWeNT; Norman, Oklahoma) said his company uses both AgNW and carbon nanotubes (CNTs) in two layers. The CNT is screen printed on top of the AgNWs, which are washed away with water and reclaimed. When AgNWs are used by themselves and adhered to the underlying film, Jansen said, they require laser patterning or photolithography. Thus, SWeNT offers an easier and quicker patterning process. The company is several months from customer sampling.

Canatu Oy (Helsinki, Finland) uses “carbon nanobuds” for its conducting medium. These bud-like structures appear on the exterior walls of CNTs when they are grown, said Canatu marketing and sales VP Erkki Soininen, but Canatu forms its directly by the reaction of gasses. The nanobuds, said Soininen, literally fall out of the reacting gasses onto a film in a roll-to-roll process. There is enough adhesion between the buds and the film so the product can be shipped in this form. The customer patterns the film and adds an overcoat and any other films needed for his application. The Canatu process produces TFCs with sheet resistances as low as 100 ohms/square at 95% transparency. Canatu has just announced its first design win, a flexible consumer product. What product? Soininen can’t say. Not yet.

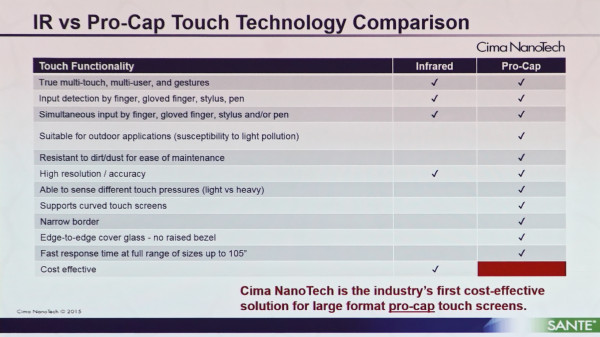

Kelly Ingham, COO of Cima NanoTech (St. Paul, Minnesota and Singapore) told me the company is currently making a major transition from manufacturing. The company is making modules itself and is ramping up high-volume film production in China. The company spent 10 years in R&D mode, so this is a very significant transition. Ingham and two other members of the strong senior management team are former 3M employees and presumably familiar with high-volume films.

The company’s Sante technology applies proprietary nanoparticles on PET or other polymer film in a wet roll-to-roll process. It then self-assembles into a random metal mesh with 3-6 micrometer conductors. The process can produce films with 25 ohms/square sheet resistance at 87% transmissivity (including the PET). The Sante’s “shading” is only a portion of that. NanoTech’s first app is a game table from a US company, in which the large display size and requirement for 6ms response time demands very low sheet resistance. The technology can go as low as 10 ohms/square for large sizes.

At Display Week, Stanford spin-out C3nano (Hayward, California) culminated a string of major announcements this year by introducing its highly flexible ActiveGard hardcoat for its AgNW TFC product. C3nano deposits an ink containing silver nanowires that overlap each other in a loose web. The wire web is open enough so light can pass through, but dense enough to provide good conductivity. C3nano’s wrinkle is “Nanoglue” technology, a catalyst-mediated process that causes the AgNWs to fuse where they cross. This results in greater conductivity for a given wire diameter, which can be used to deliver lower sheet resistance, less haze, or a combination of the two, said CEO Cliff Morris.

This is what was on the show floor. Still in laboratories are carbon nanotubes, graphene and who knows what else. For a category often thought of as simply “ITO replacements,” FTCs have become very interesting indeed. – Ken Werner