Professor Ching Tang is a well known name in the display community as one of the key inventors of OLEDs when he was at Kodak back in the 1975. But his work, recognised in 33 awards including the Jan Rajchman Prize of the SID (awarded for an outstanding scientific or technical achievement in, or contribution to, research on flat panel displays). But his work has also resonated outside the world of displays and in 2019 he was awarded the prestigious Kyoto Prize (to go with his 19 other prizes).

As part of the Kyoto prize (which includes a $1 million cash prize), the laureate gives lectures at a number of prestigious institutions and this week Tang gave a talk about his history and the development of OLED via the Blavatnik School of Government, a part of Oxford University, and a partner institution of the Kyoto Prize.

Prof. Tang was introduced by Prof. Henry Snaith, of Oxford’s Clarendon Lab, who has developed solar absorbers based on halide perovskites.

Prof. Tang was introduced by Prof. Henry Snaith, of Oxford’s Clarendon Lab, who has developed solar absorbers based on halide perovskites.

Although I have been keeping a close eye on OLEDs since the mid ’90s, I didn’t know much about the start of R&D so I joined the webinar to hear Tang speak.

The Fishing Village of Shenzen

Prof. Tang explained how he was raised in Hong Kong and attended a ‘one room school’ that was close to Shenzen, which was then ‘a fishing village’. He moved to the University of British Columbia in Canada in 1967. After getting his degree he went to Cornell to study chlorophyll photoconductivity and then moved to Kodak in 1975 where he started work on solar cells.

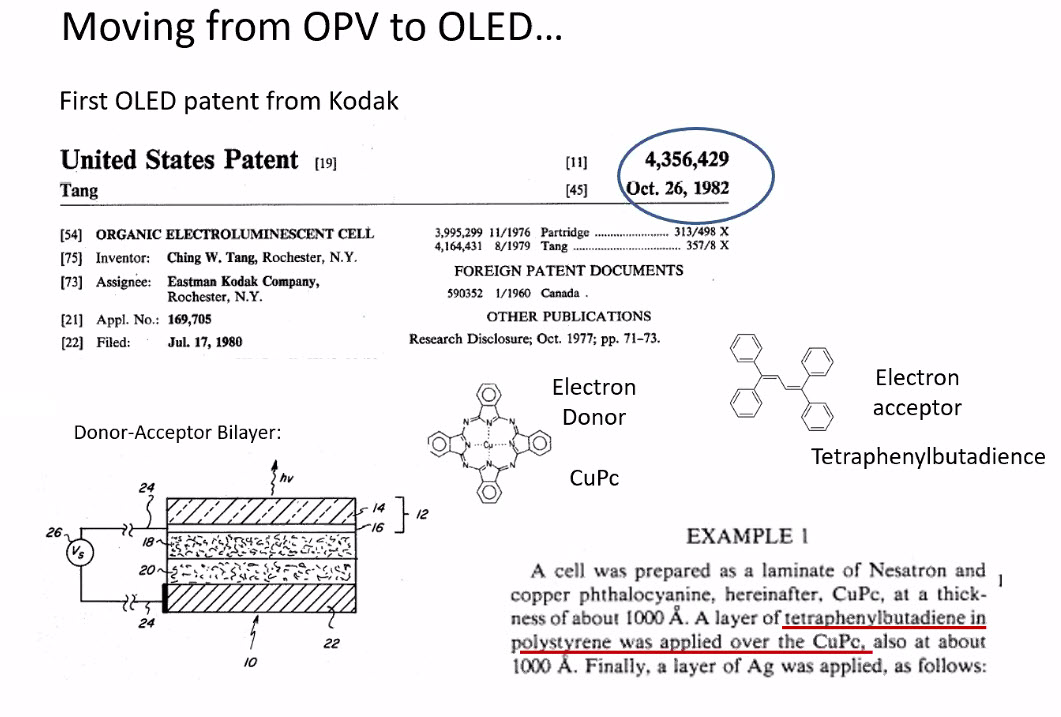

Kodak was working on xeroxography – used in photocopiers and laser printers (later) and using organic coatings to transfer inks to paper. The process used light (the image) to create a charge on the drum. Creating a charge from light is effectively what solar cells do, so Kodak was also working on this application of the core technology. Tang joined to try to make organic solar cells, but after a year’s work, although his device worked, the efficiency was just 0.2%. After several years, he got this to 1%, but compared to the 10% that inorganic cells were achieving, it was pretty poor, so he gave that up. A patent was issued in 1979, but research stopped in 1978.

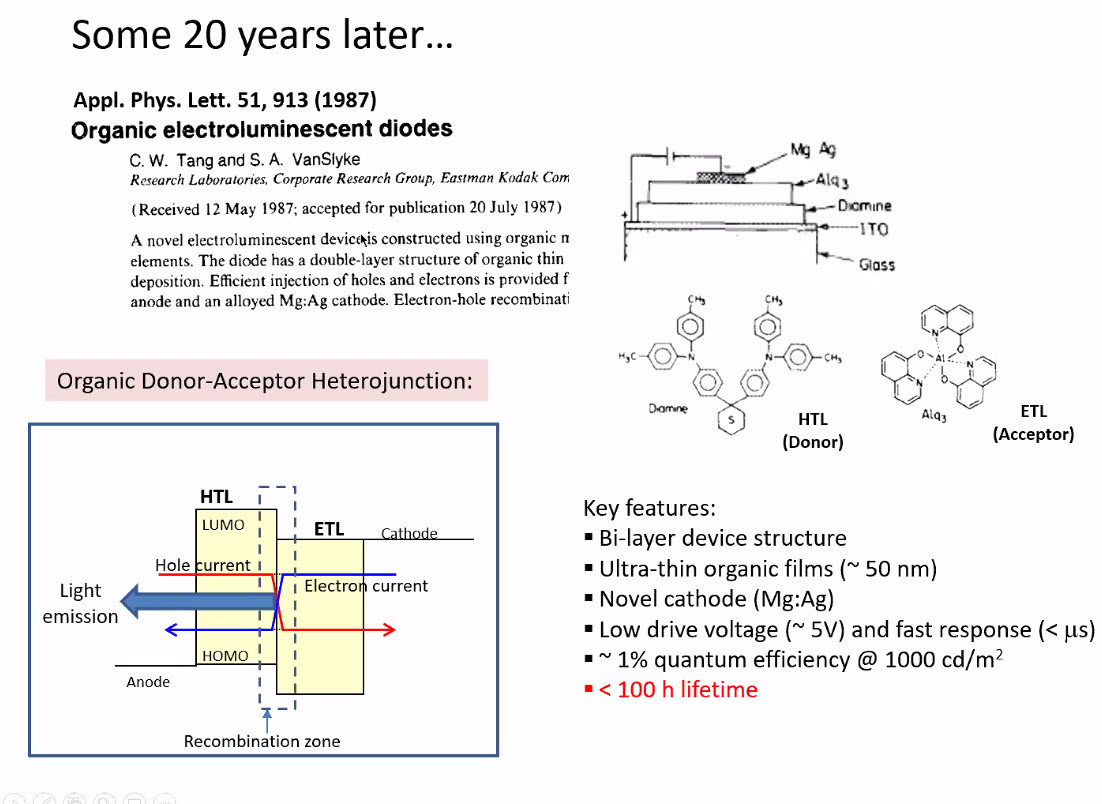

Another paper was published on the first organic thin-film planar heterojunction solar cells in 1986 (although the work was done between 1975-79. Tang said that Kodak didn’t really care about papers, just about patents).

He then looked at using the same kind of architecture as the organic photocells but using ultrathin cells and a novel cathode to produce light from charge rather than the other way round. He created a device with 1% external quantum efficiency (EQE) at 1,000 cd/m² with just 5V driving voltage. That low voltage was important as work on organic EL in the 60s had shown some blue light emission in organic liquids, but at 2,000V. The main problem he had was that the new device, which produced blue light, only lasted 100 hours.

The First OLED Patent

The first patent by Kodak on an OLED was in 1982 and in 1987 a paper that described the work was published.

The paper has been fundamental in organic electronics, according to Prof. Henry Snaith, who introduced Prof. Tang at the webinar. According to Google Scholar, the paper has been cited 18,519 times.

Google Scholar reports that this paper has been cited 18,000+ times

Google Scholar reports that this paper has been cited 18,000+ times

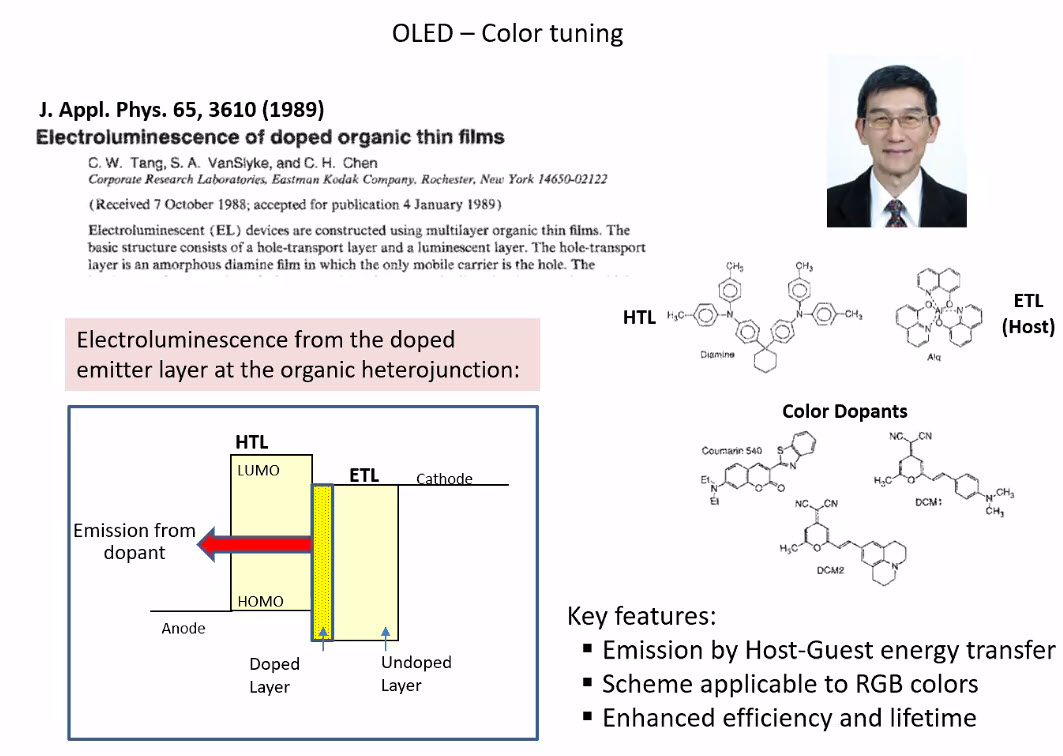

A second paper in 1989 showed how doping the luminescent layer could change the colour of the emitted light and allowed the tuning of colours. There was, Tang said, a simple host-guest energy transfer process.

The Device Gets More Sophisticated

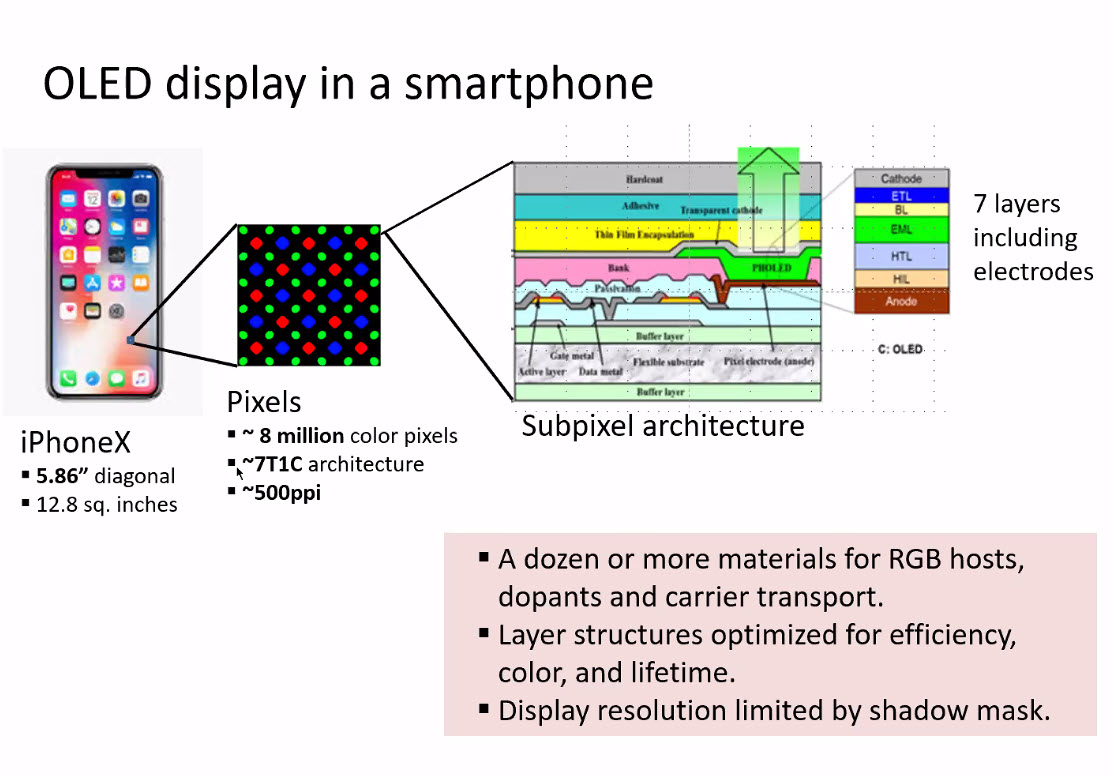

As the technology developed, the original simple architecture was gradually made more sophisticated to get better efficiency and lifetime. Eventually a seven layer architecture was created (five layers + 2 injection layers). Despite the decades of work, the best electrode still seems to be Mg:AG. Blue host materials were based on anthracene, but there are 24 isomers and so there are lots of different commercial blue host materials. The materials were incredibly sensitive to water and oxygen and Tang said that huge progress had been made to create incredibly good encapsulation.

In 1999, the next big breakthrough was in developing Phosphorescent OLEDs in work done at Princeton and UDC. That raised the potential output from 25% EQE to 100%, although so far this has only been achieved in green and red.

Work done by Prof. Adachi in Kyushu University (a graduate student of Dr Stephen Forrest, one of those that developed phosphorescent OLED) exploited the idea of delayed fluorescence, discovered much earlier, and applied it to making an emitter without heavy metal that could also give another pathway to 100% EQE.

Addressing Gets More Complex

On the back of the display, simple passive matrix addressing allowed small low resolution devices which started to come on the market in the late ’90s – initially with Tohoku-Pioneer in Yonezawa, Japan. (My Toyota Celica, bought in 2000 had one for a fuel guage, and I had another in a pioneer radio in the car – editor)

However, for better resolution and performance, active matrices were needed and these were initially based on a two transistor/1 capacitor circuit, but quickly evolved and have gone up to seven transistors/1 capacitor in the most sophisticated designs. Better transistors were needed to drive these active matrix OLEDs and Tang said that ‘Oxide TFTs were made for OLEDs’.

In a question session at the end of the talk, Prof. Tang said that there is still a lot of work going on especially in blue. He is unsure that TADF will have any advantage over phosphorescent materials when it comes to blue emitters. He said that in general host materials have to be ‘rock stable’.

He also said that correct choice of applications has helped OLED. For example, smartphones do not need the lifetime of, for example, TVs.

Prof. Tang retired from Kodak in 2006 and joined the University of Rocheste. He has added to that a professorship at the Hong Kong University of Science & Technology (he also has a number of honorary professorships).

Finally he said that it had taken 30 to 40 years to get to commercialisation and at times they ‘didn’t really know what they were doing’. It was a process of gradual discovery and it had been important to keep working on the problem, without giving up when it got tough. (BR)