One of the challenges of making LEDs and, in particular, microLEDs, is to keep them consistent, even though the structures of red, green and blue LEDs are usually different, with blue based on Indium Gallium Nitride (InGaN), while red and green are based on phosphides or from colour conversion from blue. However, in theory, all colours could be made from InGaN, but this is made impossible because of lattice mismatches.

European specialist semiconductor material maker, Soitec, from Grenoble, and a growth from the CEA/Leti technology cluster in that city, has developed a new substrate called InGaNOX that fixes the mismatch problem, allowing the use of the same structure for each colour. The company said it has made 100mm wafers with red, green and blue LEDs and can scale to 300mm with the material on silicon, glass or sapphire wafers. The size of devices can be reduced down to 5µm x 5µm.

Leti can grow RGB LEDs on InGaNOX. Image:Soitec

Leti can grow RGB LEDs on InGaNOX. Image:Soitec

The group plans to develop optimised LED devices that can be measured to check the external quantum efficiency (EQE).

Soitec said that it can make substrates with mixed lattice parameters to allow the growth of different coloured LEDs. That would simplify issues in making microLED displays. The group also said that it could be used to make high efficiency green LEDs without colour conversion and make control easier by using the same materials for all the LEDs in the device.

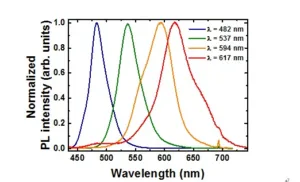

Soitec made these colours on its InGaNOX substrates, Image:Soitec

Analyst Comment

A hat tip to LEDInside for this story. We have followed up with Soitec to get more information, if we can. A lot of technology comes out of the CEA/Leti cluster in Grenoble. (08 Leti Developing Microdisplays Using GaN Hybrid) (BR)