There has been a lot of discussion about why Samsung is going for QDOLED technology, given the complications, the technology risk and the amount of money involved. Several times I have found myself thinking “They must know something that we don’t”. It turns out that they certainly do – as was detailed in an article published yesterday in the prestigious publication, “Nature”.

We’re planning to publish a more detailed look at the paper once we have had a chance to absorb it (and after the Thanksgiving holiday in the US!). However, I thought I’d take a very high level look at the issue from a commercial point of view (as I’m no chemist. I love listening to someone like Jason Hartlove of Nanosys wax lyrically on the science, but 90% is out of my comfort zone!)

Samsung, of course, is the giant of small OLEDs – it has a completely dominant market share of the market. It had 78% of capacity in 2017 for small OLEDs in 2017 and will still have 38% in 2025, despite Chinese investments, according to DSCC.

On the other hand, Samsung had a huge project to build large OLEDs that was just too technically difficult. At the time, there were several challenges (all as far as I know – let me know if you know differently!):

-

The firm planned to use LTPS for the backplane. It has never been in production at anything beyond 27″ (and mostly much smaller) as far as I know.

-

There has never been a successful (in volume production) method of depositing the OLED materials on large substrates in individual subpixels). Samsung had a concept known as LITI, using lasers, but in the end it had to use shadow mask methods and these have never been scaled in mass production for OLEDs beyond notebook size. (LG deposits its materials in layers, not in subpixels. Samsung does deposit as subpixels in its small OLEDs)

-

Blue OLED material lifetimes and efficiency were not good enough. (they have improved, but this remains a major challenge).

-

There were challenges in encapsulation, although those have been solved for now using inkjet techniques.

However, Samsung has to get out of LCD production because of the unequal competition from Chinese makers that have access to effectively free capital and has said that it will do so by 2025.

Quantum Dots

Samsung has been working on QD technology in its production products for some years now. The company has developed QD backlights which rely on the quantum dots being excited by photons. A film between the blue backlight has QDs encapsulated in it that converts some of the light from blue to red and green. That’s what Samsung is shipping as QD technology now.

The next step was to develop the idea of putting the QDs where the colour filter was in an LCD. That would avoid the inefficiency of converting the light behind the LCD cell and then filtering at the front. The concept also promised to solve the issues of weak viewing angle performance. Unfortunately, it has proved a bit too tricky, with a colour filter still needed because it is hard to get the QDs to absorb all the blue light in the red and green pixels, and because of the need to move the polariser inside the LCD cell. So, that technology has not made it into production (although I’m sure someone in a lab is still looking at it).

Samsung also tried the ‘QDOG’ approach that put a QD layer between a glass light guide plate and the LCD cell. This made the encapsulation (which is expensive) easier and made the panel very thin, but this has remained a niche at the moment. (Will QDOG Have its Day?)

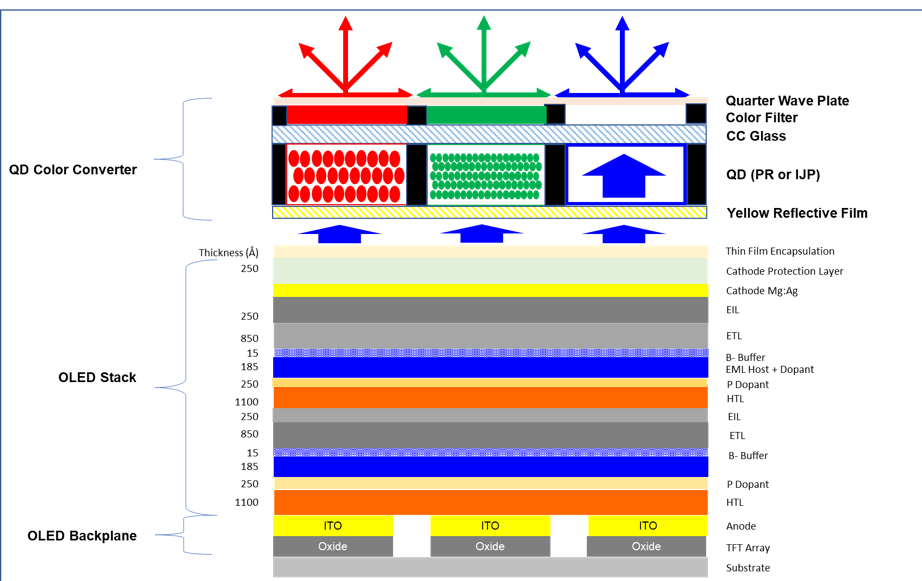

QDOLED

So, Samsung has been working on the QDOLED idea and has started the conversion of an LCD fab to bring this to production. This uses the layered approach of LG’s OLEDs (which LG itself acquired from Kodak) and uses blue OLED material(s) on the backplane with a QD conversion layer at the subpixel level. Unfortunately, the same problem of blue absorption is seen, so as well as the conversion layer, a colour filter is needed which adds complication and reduces efficiency (and in UK language is a ‘bit of a bodge’). Multiple blue levels may also be needed (at least a dark blue and a light blue, but possibly multiple light blue layers to reduce the level at which the material is driven to improve lifetime).

QDOLED allows Samsung to compete with the performance of LG’s OLEDs but (we assume) with higher efficiency and longer life as you won’t need to drive the blue so hard. It would also benefit greatly from potential blue material developments (which could be from Cynora, Kyulux or someone else).

The QD OLED Layers. Source: DSCC/OLED-A Quarterly OLED Material Report

The QD OLED Layers. Source: DSCC/OLED-A Quarterly OLED Material Report

For more see our DD article (Have Your Cake and Eat It Too with QD-OLED)

QDLED

The ‘final’ step that has been on the roadmap was a switch to QD LEDs rather than O LEDs. That is to say, the idea of using an OLED-like structure, but with QD materials rather than the organic ones. That might, it was thought, solve the problems of life time and efficiency in OLEDs, with the QDs being electrically stimulated rather than by photons. However, the science has been tricky.

That’s where the article in Nature comes in.

Samsung’s own scientists have developed a high efficiency, long lifetime QD architecture that allows QDLEDs to be made, critically without using cadmium. In fact, the development has achieved higher efficiencies. That’s a big deal.

We’ll be reporting in more detail on the development once we have fully absorbed it (unless we need a filter ;-)). If you want a review of the paper or want to buy the paper, it’s here.

Now, the development as published is for a red material. However, you can be sure that the other colours are being worked on and the insights that Samsung has obtained in the fundamental mechanisms of the degradation process may well be helpful in developing blue and green. If these materials could be developed, it should be (relatively) easy to convert the QDOLED fab that is being built to make the QDLEDs. (BR)

Analyst Comment

Of course, today is Thanksgiving Day in the US, but despite the holiday, our QD specialist, Pete Palomaki, told me that he didn’t think, after a quick look, that this development is very special. However, he is going to have a good look and we’ll return to this topic. (BR)