Susceptibility to water and oxygen is still one of the biggest hurdles to overcome to achieve the long-term reliable operation of flexible OLED devices. Therefore, a high-performance encapsulation method is critically important to protect organic electronic devices from the penetration of water vapor and oxygen.

Thin film encapsulation (TFE) is one of the most widely investigated encapsulation methods. OLEDs require a thin film encapsulation (TFE) with high barrier performance and mechanical reliability to ensure reliable operation. TFE consists of an alternating stack of inorganic and organic thin layers directly deposited on the target devices. Generally, the inorganic layer is responsible for blocking the penetration of contaminants, and it is essential to fabricate a defect-free inorganic thin film to guarantee the barrier’s performance. Multiple alternating stacks of inorganic layers with organic layers are also considered more efficient in terms of protective performance.

Adding Alumina Into the Mix

To address these challenges, researchers have proposed various approaches, including the development of novel substrates and the use of new bonding techniques. In a study to be published in an upcoming issue of the Organic Electronics journal, researchers have proposed a multi-layered structure consisting of Al2O3 and acrylic materials with wavy stacking interfaces. This approach aims to break the trade-off relationship between high flexibility and low permeability by reducing the tensile strain of the brittle Al2O3 film under bending.

Al2O3, also known as aluminum oxide or alumina, is a white or off-white crystalline solid that is commonly found in nature as the mineral corundum. Its excellent physical and chemical properties make it widely used in various industrial applications. One of the key properties of Al2O3 is its high melting and boiling points. With a melting point of 2072 °C and a boiling point of 2980 °C, it is useful in high-temperature applications.

Another important property of Al2O3 is its hardness. It ranks 9 on the Mohs hardness scale, second only to diamond, making it suitable for applications that require abrasion resistance. In addition, Al2O3 is highly resistant to chemical attack and can withstand exposure to acids, bases, and many other chemicals. It is an excellent electrical insulator and is commonly used in electronic components. It is also optically transparent in the visible and infrared regions of the electromagnetic spectrum, making it useful in applications such as windows and lenses.

On a side note, Al2O3 is biocompatible, meaning it does not cause an adverse reaction when implanted in the human body. This property makes it suitable for use in medical implants and prosthetics. Therefore, overall, the properties of Al2O3 make it a versatile material that is used in a wide range of applications, including ceramics, abrasives, electronics, and medical devices.

As a result, Al2O3 has a long history in the field of flexible electronics. In the early 2000s, researchers began to explore the use of Al2O3 as a material for encapsulating flexible electronics. One of the first studies focused on the deposition of thin films of alumina using atomic layer deposition (ALD) on flexible substrates.

Since then, numerous studies have investigated the use of Al2O3 in flexible electronics, particularly in the context of OLED displays. One of the main challenges in using alumina for OLED encapsulation is its brittleness, which can lead to cracking and failure under bending or stretching.

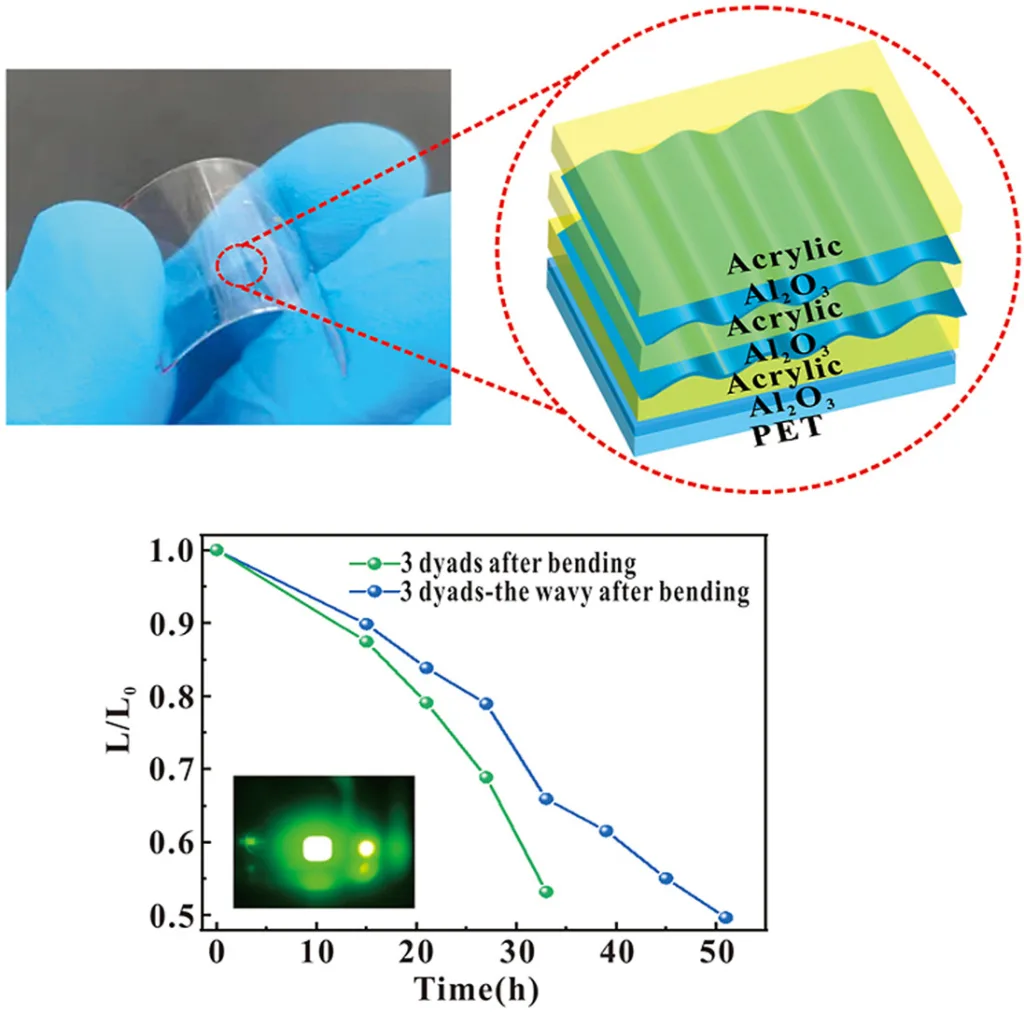

In this study, the researchers found that a 3-dyad wavy Al2O3/acrylic multi-layered structure with specific periods and amplitudes was preferred to minimize stress under bending. A dyad is a pair of two elements or parts that are considered as a single entity or unit. In the context of the manufacturing process of a display, a 3-dyad wavy Al2O3/acrylic multi-layered structure refers to a combination of three pairs of alternating layers of Al2O3 and acrylic with wavy stacking interfaces. Each pair is considered a dyad, making a total of three dyads in the multi-layered structure. To achieve these wavy structures, they proposed a novel manufacturing approach that combines argon plasma treatment and soft-lithography.

The study found that the WVTR of a 3-dyad wavy Al2O3/acrylic multi-layer was 3.18 × 10−5 g/m2/day after 100-iteration bending with a bending radius of 1 cm, corresponding to a tensile strain exceeding 1.09%. The WVTR for an OLED should be less than 10−6 g/m2/day for the broadest range of use cases, but this result is adequate protection for most applications, and cost-effective, particularly for those displays that are not to be subjected to harsh environments. Experimentally, the lifetime of OLEDs encapsulated using Al2O3/acrylic multi-layers with wavy structures and under the same bending condition was around 50 hours, showing a 40% increase compared to that without wavy structures.

In addition to the wavy encapsulation layers discussed in this study, other studies have explored alternative materials and structures for encapsulation layers. For example, some researchers have proposed using graphene as a barrier layer for OLED encapsulation. Graphene has excellent barrier properties and can be used to create flexible encapsulation layers with high barrier performance. Other studies have also explored the use of organic materials such as polymeric and inorganic materials such as ceramics. These materials offer several benefits, such as high flexibility, low cost, and high barrier performance.

In terms of the encapsulation structure, some studies have proposed multilayered encapsulation structures, including hybrid organic-inorganic structures and polymer-inorganic structures, to achieve high barrier performance and mechanical reliability. Another promising approach for encapsulation is the use of thin-film encapsulation (TFE) with atomic layer deposition (ALD) technology. TFE with ALD can provide high barrier performance, mechanical reliability, and excellent conformal coating of the encapsulation layer.

Ongoing research in this area aims to develop new materials and techniques for achieving reliable and high-performance operation of flexible and stretchable electronic devices, including OLEDs and flexible displays. The use of novel materials, structures, and fabrication techniques can provide improved mechanical and barrier properties, enabling the development of reliable and robust flexible electronic devices. The quest is ongoing.

Reference

Peng, Y., Weng, Y., Chen, G., Hong, D., Wang, W., Chen, C., Zhou, X., Zhang, Y., Wu, C., Guo, T., & Yan, Q. (2023). Improved mechanical properties of Al2O3/acrylic laminates for flexible thin film encapsulation by introducing wavy interfaces. Organic Electronics, 117, 106791. https://doi.org/10.1016/j.orgel.2023.106791