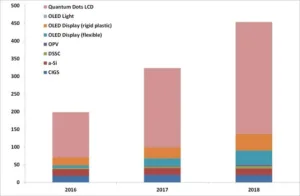

IDTechEx has predicted that flexible barrier film market will be worth $850 million by 2026. Interest will mainly be driven by quantum dot (QD) LCD displays and flexible OLED displays, both of which require these components.

Flexible encapsulation aims to replace the rigid glass encapsulation used for OLED displays in, for example, smartphones and tablets. This enables new form factors, such as foldable devices, which are more robust.

There are three common approaches to encapsulation:

- In-line deposition (aka direct or thin film encapsulation). A barrier is applied directly to a device during fabrication, in a vacuum and/or inert atmosphere. Samsung uses this method for its rigid plastic displays.

- Barrier film encapsulation. The barrier film is manufactured on a polymer substrate, and is laminated onto the device with a pressure-sensitive adhesive. These types of film are often used in the manufacture of QD enhancement films (QDEFs).

- Hybrid encapsulation. A combination of in-line and barrier methods. Hybrid encapsulation is the in-line deposition of a barrier construct, with the subsequent lamination of a barrier film using a pressure-sensitive adhesive. LG uses this approach on its G-Flex rigid plastic display.

IDTechEx’s report can be found at http://tinyurl.com/oyruqh8.