Last week was the return of the in-person Phosphor & Quantum Dot Industry Forum. It’s always a challenge to distil conferences like this into key takeaways, but here is my best shot at highlighting three trends I observed: Energy, Color, Non-display applications.

Energy

There was a new focus on energy this year in a number of presentations. Nanosys CEO Jason Hartlove kicked off the conference with a call to action. We need to consider more seriously the impact of modern displays on energy which means both energy use (climate change) and energy independence which has become an important topic in today’s world. One statistic that he presented that stuck with me is that 4.6% of household energy consumption in the US comes from displays. Yet we rarely think about displays as an energy hog. TVs, being as big as they are (and getting bigger), are the worst culprit, and you may have heard about the EU proposing legislation that would limit energy use of displays in a way that would essentially eliminate 8K in Europe so clearly people are thinking about this.

Intel highlighted its efforts to reduce power consumption (aka extend battery life) in notebooks via a combination of sensing and display advancements. Essentially, Intel plans to provide a dynamic display/computing environment that will only use power when it’s required, where it’s required. Think auto-dimming lights in the freezer aisle to conserve energy, or a car engine that shuts off at stop lights to save fuel.

The panel discussion which I was a part of continued to probe the idea of using advanced technology to reduce energy consumption. A common theme was not necessarily going bigger and brighter, but rather using the tools and materials at our disposal to enhance the display experience. Which segways nicely into the next topic…

Color

Not surprising that color was front and center at a conference about phosphors and QDs. But the focus on mixed systems was new. I have written (and published videos) on the topic of using multiple types of color-converting materials in displays before. At least four talks during the 2-day conference mentioned or highlighted the shift that has occurred in the past handful of years. No longer is it just a single color-converting material that is available to display makers, and some have gotten creative by taking a “mix-and-match” approach. Extruded QD diffusion plates paired with red KSF and green phosphor on LEDs seem to be gaining momentum, although I have yet to see real numbers on how many displays use this architecture. Of course we can now group OLED into this new mixed system architecture, since the launch earlier this year of Samsung’s QD-OLED panel.

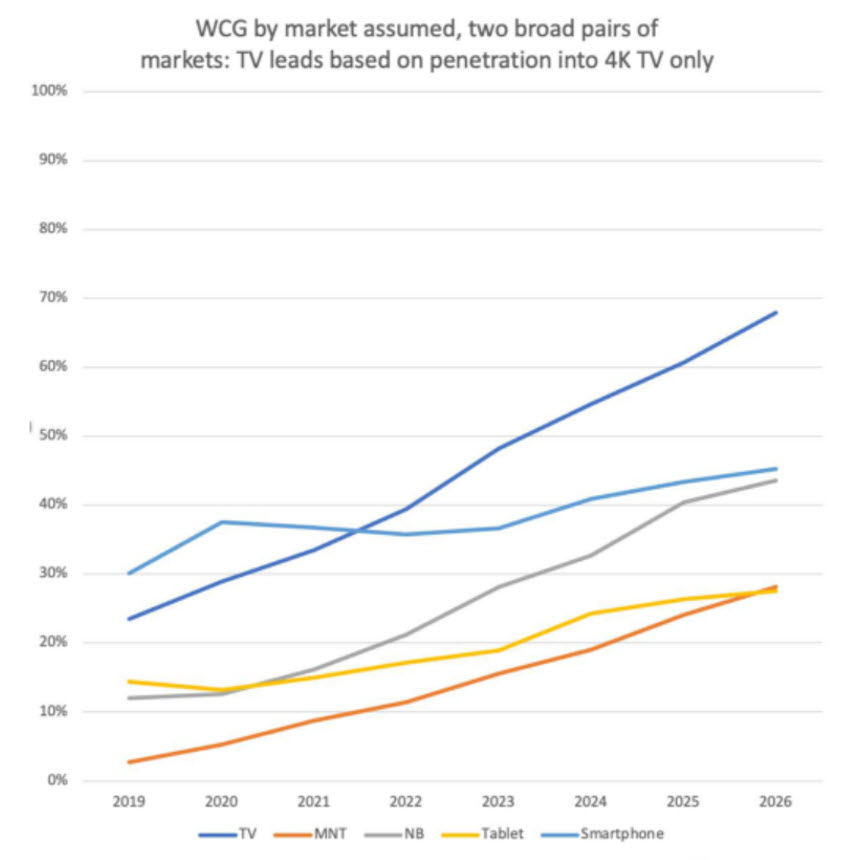

Wide Color Gamut continues adoption cycle across all display types. Source: Hendy Consulting, Phosphor/QD Summit 2022

Wide Color Gamut continues adoption cycle across all display types. Source: Hendy Consulting, Phosphor/QD Summit 2022

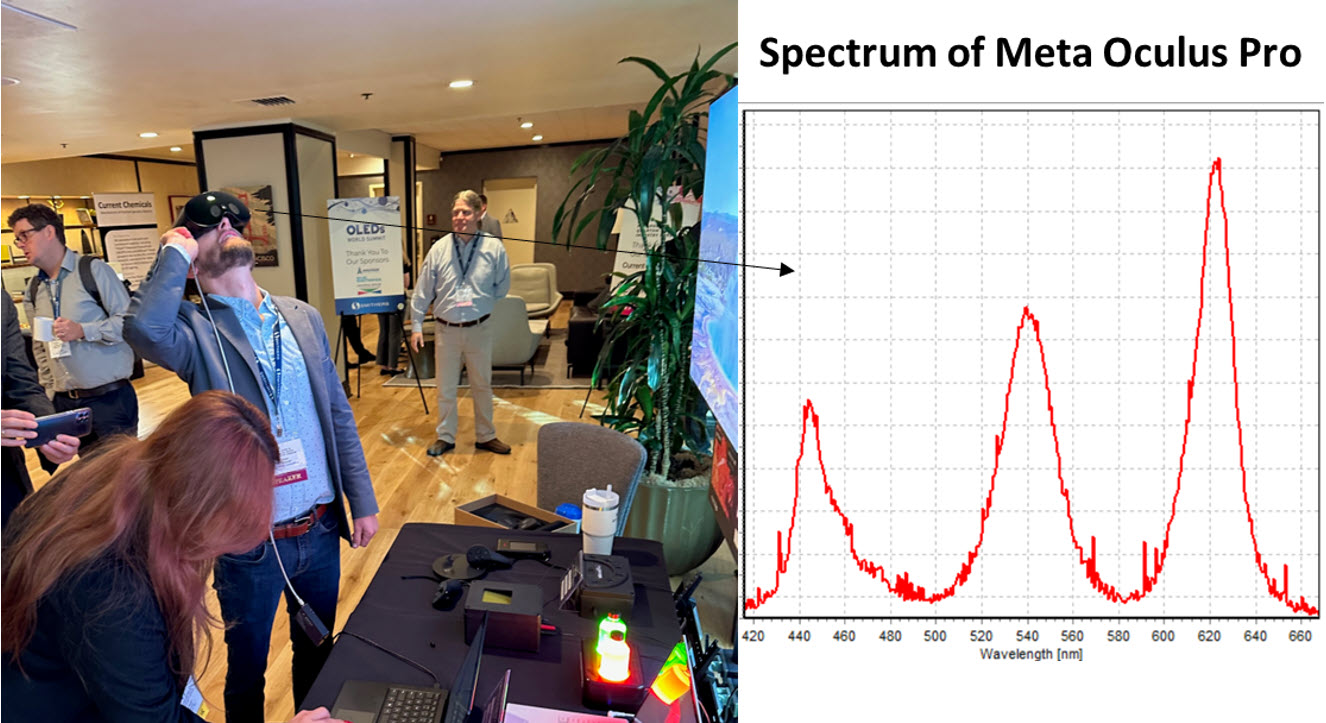

Nanosys had some good-looking demos, including a QD-OLED as well as a Meta Oculus Pro AR/VR headset. I had to confirm that it does, in fact, contain QDs so I had to pull out my spectrometer to test it. The optical spectrum supports the claim!

Measuring the spectrum of an AR/VR headset is not trivial since it will only activate the display with the headset on!

Measuring the spectrum of an AR/VR headset is not trivial since it will only activate the display with the headset on!

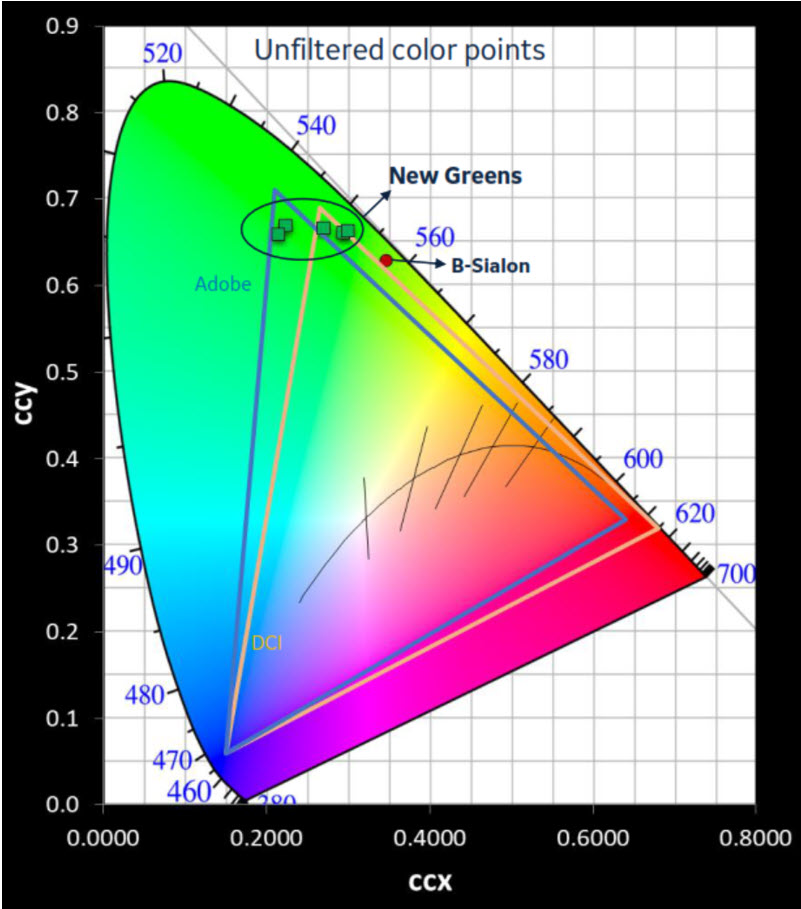

On the phosphor side of things, both GE and Current Chemicals shared their development of green phosphors to complement KSF red. While the performance in terms of color gamut is not quite as good as a green QD, there is something to be said for the stability of some phosphors for on-chip (LED) applications. It should be noted that phosphor developers are not shying away from the film approach either. With mini-LED displays on the rise, it becomes more and more complicated to put phosphors on-chip which means remote parts (films) may be the way to go, even for phosphors. To make the point, there was a demo being shown of a mini-LED LCD car display leveraging a phosphor film.

GE’s series of five “new green” phosphors show good match to DCI-P3 and Adobe RGB color spaces (without color filtering). Source: GE, Phosphor/QD Summit 2022

GE’s series of five “new green” phosphors show good match to DCI-P3 and Adobe RGB color spaces (without color filtering). Source: GE, Phosphor/QD Summit 2022

Non-display applications

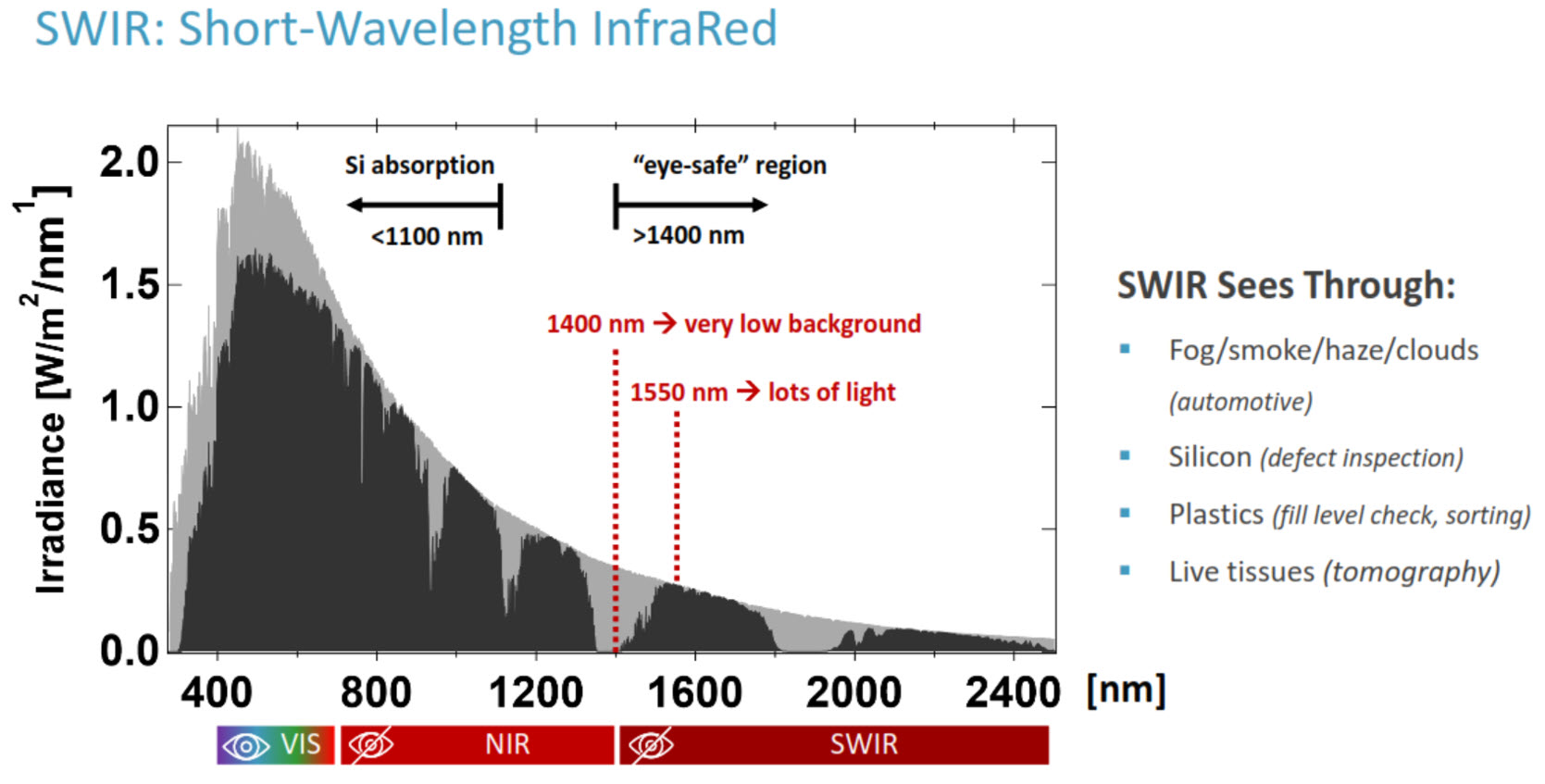

Believe it or not, for many people involved in QD technology development the world does not revolve around displays. Infrared detection has become one of the next big commercial application for QDs. While the size (area) of this application may be small compared to displays, the value-add from QDs is quite clear. Four companies presented on infrared photodetectors enabled by QD technology to make high-resolution, low-cost photodetectors for applications such as industrial inspection, vision, and ultimately autonomous vehicles. The QDs used in these applications are cousins of the CdSe and InP used in displays. PbS and InAs are the two most often utilized since their bandgaps can be tuned to absorb in the useful region of near-infrared (NIR) and short-wave infrared (SWIR). There are already detector products on the market containing PbS QDs, and I expect InAs is not too far behind.

Explanation of SWIR spectrum and why we need to be able to detect photons there. Source: Imec, Phosphor/QD Summit 2022

Explanation of SWIR spectrum and why we need to be able to detect photons there. Source: Imec, Phosphor/QD Summit 2022

QD company UbiQD would argue their QDs are already penetrating the next big market(s) for QDs. Their two major products currently are security inks and greenhouse light conversion films. The greenhouse films work in much the same way a QD film works in a display, but in this case the QDs convert UV and blue energy from the sun into red wavelengths which can benefit crop growth (yields, fruit size, etc.). As for security inks, their recent announcement of a collaboration with security company SICPA indicates that we may soon (already?) be interacting with QDs in our daily lives without even knowing it! Keep an eye out for their solar power-generating windows too.

It was a good return to in-person for the Phosphor/QD/OLED Summit. While attendance was down (not surprising), the networking and community-building factors remain a strong selling point for attending. (PP)

Peter Palomaki is the owner and chief scientist at Palomaki Consulting, a firm specializing in helping companies solve big problems at the nanoscale. His utilizes his expertise in quantum dots and materials chemistry to solve challenging problems with clients large and small.