Mirrorcle Technologies Inc. (Richmond, CA) recently provided public demonstrations of a prototype MEMS-based programmable light source. The purpose of the demonstrations was to illustrate the qualities of the image that can be projected usng the company’s MEMS technology. More specifically, the purpose was to demonstrate that the projected image could be arbitrarily shaped and have a high contrast ratio.

The basis of the demonstration was the company’s gimbal-less two-axis scanning MEMS mirror device. This device can provide optical beam steering across two axes. The Mirrorcle Technologies prototype uses so-called ‘bias-differential quad-channel electrostatic MEMS drivers’. Some features and specifications of the device include:

- The ability to deflect laser beams or images to optical scanning angles of up to and, in some operating modes, even greater than 32 degrees.

- Continuous full speed operation of the actuators that drive mirror tip – tilt rotation dissipates less than 1 mW of power.

- MEMS mirrors are made entirely of monolithic single crystal silicon, resulting in excellent repeatability and reliability.

- Smaller and medium mirror sizes are manufactured as integrated parts of the silicon MEMS chip. Larger mirrors are bonded onto actuators, allowing for custom mirror sizes.

- Flat, smooth mirror surfaces are coated with a thin film of metal with high broadband reflectance.

Mirrorcle Technologies MEMS can operate in three different modes as follows:

- Point-to-point or quasi-static mode: Both axes use the wide bandwidth of operation of the device from dc to some frequency. In this mode, the mirror can hold a dc position, move at a uniform velocity or perform vector graphics.

- Mixed mode: One axis is used in quasi-static mode and the other axis is used in resonant mode. A typical use case is to run one axis very fast (e.g. few kHz,) to create horizontal lines and to run the other axis with a sawtooth-like waveform to create a raster pattern that covers a rectangular display or imaging area.

- Resonant mode: Both axes use the narrow, high gain resonance to obtain large angles of deflection, relatively low voltages and high speeds. Motion is limited to very narrowband, sinusoidal trajectories with a phase lag to the applied voltage. Resulting 2D motion describes circles, ellipses and various higher order Lissajous patterns and can be modulated at some rate.

Mirrorcle Technologies offers a variety of MEMS products having different sizes and device packaging. Specifications typical to all model MEMS devices offered by the company include:

- Surface roughness:less than 10 nm rms

- Mirror radius of curvature:greater than 5 m

- Mirror coating:aluminum or gold

- Positional repeatability: better than 0.001 degree at room temperature

- Operating temperature: -40°C to 125°C

- Fused silica optical window: windows are removable and come with an antireflection coating that can be optimized for several different wavelength ranges.

- Optical power handling: up to 2W any mirror, any wavelength. Above 2W depends on mirror size, coating, and wavelength.

- First resonant rotation frequency:greater than 3 kHz for both axes for small mirror sizes, greater than 1.2 kHz for 2.0 mm size and etc.

The prototype device used in the demonstration included a high power laser beam having a wavelength of about 450 nm. The beam was programmably directed onto a 10 mm x 10 mm phosphor plate where it created a very high brightness and luminance image. This image was projected by a projection lens in a desired direction.

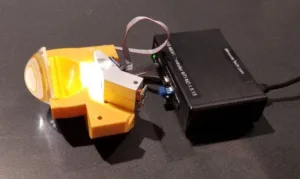

A video discussing Mirrorcle Technology’s product line and technologies can be found at the end of this article. The photograph below shows Mirrorcle’s programmable light source.

The prototype programmable light source used in Mirrorcle’s demonstrations.

The outgoing beam is fully programmable in terms of shape, brightness and direction by use of MirrorcleDraw software available from Mirrorcle Technologies or from a customers’ own applications built with Mirrorcle’s SDKs. -Arthur Berman

Mirrorcle Technologies, Christian Thiel, 510-524-8820, [email protected]